Preparation and application of metal organic framework material Ni-based MOF-74

A metal-organic framework, MOF-74 technology, applied in scattering characteristics measurement, color/spectral characteristics measurement, air quality improvement and other directions, can solve the problems of small detection range of the sensor, complicated testing, cumbersome preparation process, etc., to achieve a simple inspection process The effect of easy operation, low preparation cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

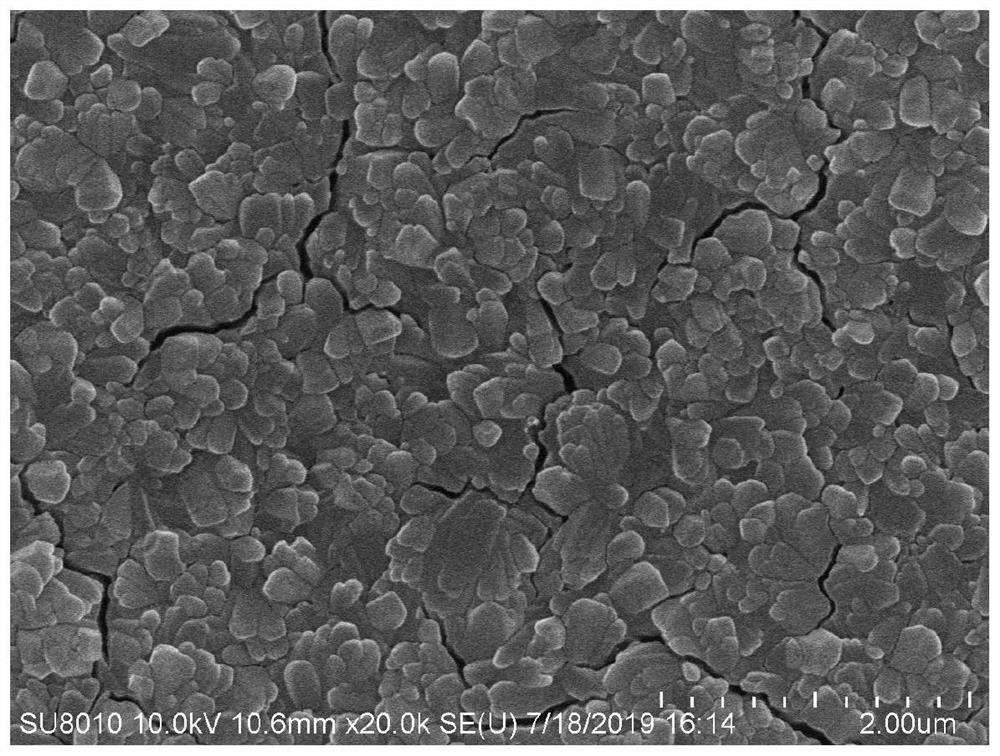

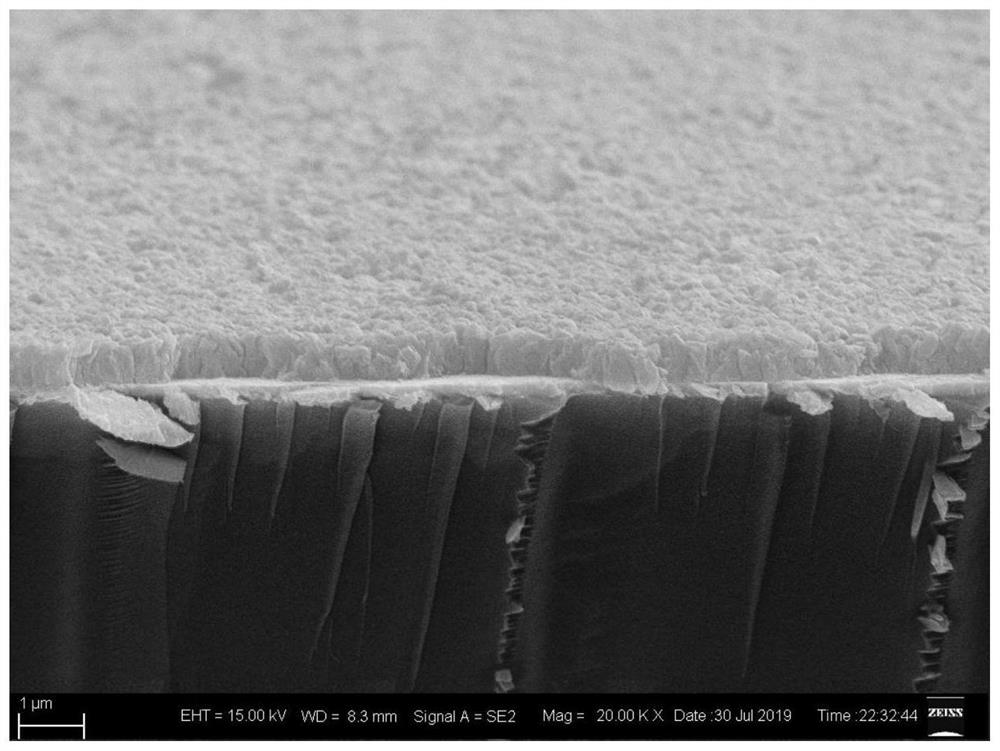

[0019] Embodiment 1: This embodiment is a preparation method of metal organic framework material Ni-based MOF-74, which is realized according to the following steps:

[0020] 1. Use detergent, acetone, deionized water and absolute ethanol to ultrasonically clean the ITO glass in turn, and then perform plasma hydrophilization treatment after drying to obtain the treated ITO glass;

[0021] 2. Using DMF as solvent, prepare 1~10mmol / L Ni(NO) 3 ) 2 ·6H 2 O and 1~10mmol / L 2,5-dihydroxyterephthalic acid solution;

[0022] 3. Take the above Ni (NO 3 ) 2 ·6H 2 O, 2,5-dihydroxyterephthalic acid solution and deionized water were mixed and transferred to a 6 mL round-bottomed glass tube. It is placed in a reaction kettle and reacted at 110-130° C. for 10-14 hours to obtain a metal-organic framework material, which is Ni-based MOF-74, and the preparation method is completed.

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ultrasonic cleaning time in step 1 is 15-25 minutes. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the plasma hydrophilization treatment in step 1: the dried ITO glass is soaked in a 1 mol / L KOH ethanol solution for 30 minutes. Other steps and parameters are the same as in the first or second embodiment.

PUM

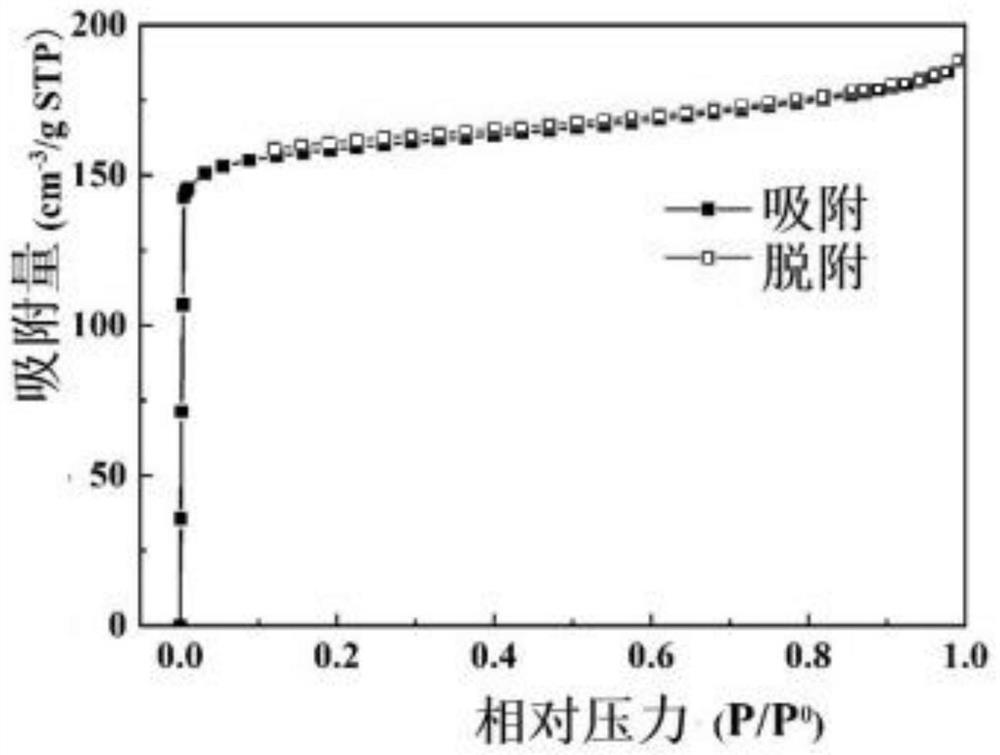

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com