Lithium iron phosphate material, and preparation method and application thereof

A lithium iron phosphate and lithium source technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of complex modification process and inability to industrialize production, and achieve easy repetition and amplification, easy control, and energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of lithium iron phosphate material comprises the steps:

[0065] (1) Lithium hydroxide, ferrous oxalate, phosphoric acid, water, urea and ethylenediaminetetraacetic acid are mixed uniformly to obtain a raw material mixed solution, the lithium element in the lithium hydroxide, the iron element in the ferrous oxalate, The mol ratio of phosphorus element in phosphoric acid and water is 3:1:1:51, and the content of described urea is 1wt% of lithium hydroxide, ferrous oxalate and phosphoric acid total amount, and the content of described ethylenediaminetetraacetic acid is 0.5wt% of the total amount of lithium hydroxide, ferrous oxalate and phosphoric acid;

[0066] (2) The raw material mixed solution is subjected to a hydrothermal reaction at 140° C. under a pressure of 5 atm, and the reaction time is 5 hours to obtain a pre-product;

[0067] (3) After aging the pre-product for 5 hours, filter it, and then dry it at 80°C for 18 hours to obtain a lithium...

Embodiment 2

[0069] The difference from Example 1 is that the pressure in step (2) is 1 atm.

Embodiment 3

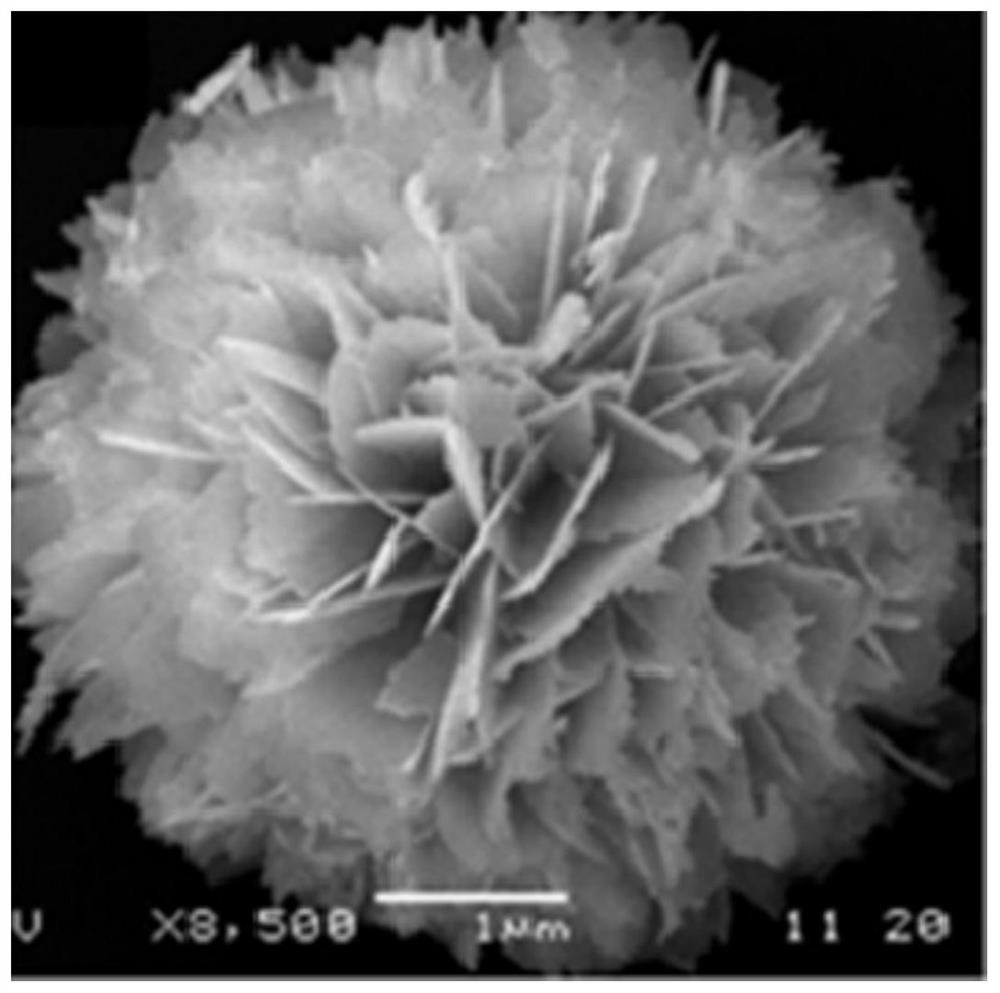

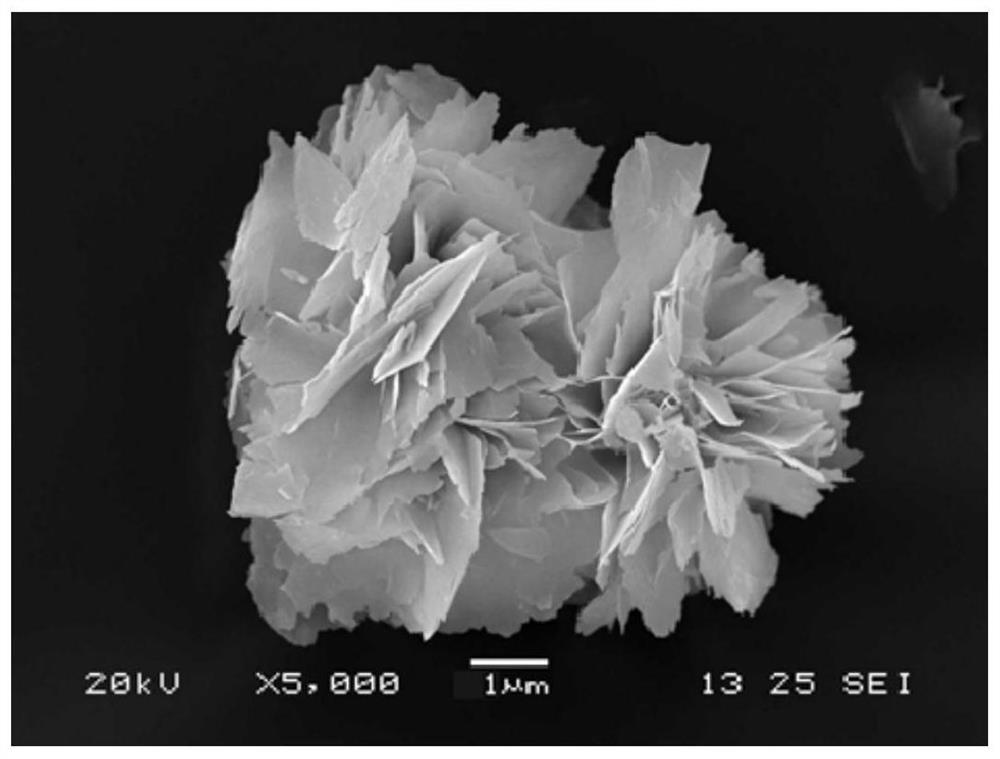

[0071] The difference with Example 1 is that the pressure in step (2) is 35 atm, and the obtained lithium iron phosphate material such as figure 2 As shown, it can be seen from the figure that the morphology of the obtained lithium iron phosphate is a three-dimensional spherical flower structure formed by stacking sheet-like structures, and the sheet-like structures of lithium iron phosphate are not bonded. Compared with the phosphoric acid obtained in Example 1 The pore size of the iron-lithium material is small and the packing density is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com