Method for recovering carbon fibers from waste carbon/carbon composite

A technology of carbon-carbon composite materials and recycling methods, applied in the production of bulk chemicals, etc., can solve the problems of poor quality of recycled fibers, loss of mechanical properties, low production efficiency, etc., achieve uniform heating, fast heating speed, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

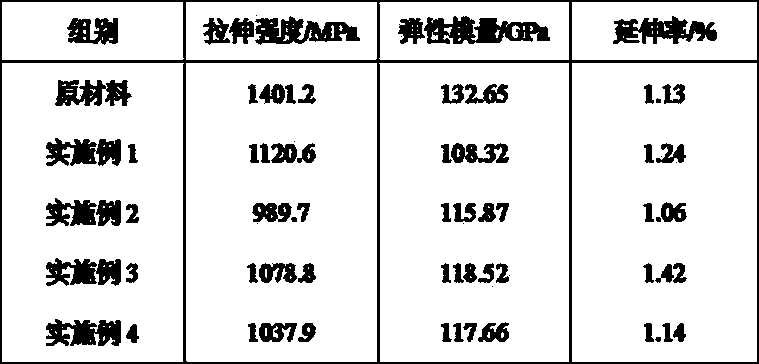

Examples

Embodiment 1

[0029] In this embodiment, the method for microwave-assisted supercritical recovery of carbon fibers in carbon-carbon composite materials includes the following steps:

[0030] (1) Carbon-carbon composite waste pretreatment: cutting resin-based carbon-carbon composite waste into 10cm 3 The left and right blocks are added to the supercritical convection high-pressure hydrothermal reactor; the inner tank of the supercritical convective high-pressure hydrothermal reactor is made of high-density polytetrafluoroethylene;

[0031] (2) Treatment of nitric acid and sodium hydroxide aqueous solution: prepare a nitric acid solution with a mass concentration of 20% and a sodium hydroxide solution with a mass concentration of 20% with deionized water, and combine resin-based carbon-carbon composites equivalent to those described in step (1). Add the nitric acid solution and sodium hydroxide solution 5 times the weight of the material waste into the supercritical convection high-pressure h...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is only:

[0038] Step (2), use deionized water to prepare the mixed acid of hydrochloric acid and acetic acid with mass concentration of 10%, and the mixed alkali solution of potassium hydroxide, sodium carbonate and sodium bicarbonate with mass concentration of 50%, and the weight is the step ( 1) The mixed acid solution of hydrochloric acid and acetic acid and the mixed alkali solution of potassium hydroxide, sodium carbonate and sodium bicarbonate, which are twice the weight of the resin-based carbon-carbon composite material waste, are added to the supercritical convective high-pressure In the hydrothermal reaction kettle, microwave is used to heat the reaction kettle, and the microwave power is adjusted to 10KW to raise the temperature inside the kettle to 120°C, and keep at this temperature for 1min;

[0039] In step (3), a mixture solution of ethanol, propanol, butanol, and benzyl alcohol with a mass concen...

Embodiment 3

[0045] The difference between this embodiment and embodiment 1 is only:

[0046] Step (2), using deionized water to prepare a mixed acid solution of formic acid, sulfurous acid and acetic acid with a mass concentration of 50%, and a mixed alkali solution of ammonium carbonate, ammonium bicarbonate, and sodium bicarbonate with a mass concentration of 10%, Mix the mixed acid solution of the formic acid, sulfurous acid and acetic acid with a weight equivalent to 3.5 times the weight of the resin-based carbon-carbon composite material waste in step (1) and ammonium carbonate, ammonium bicarbonate, and sodium bicarbonate Alkali solution is added into the supercritical convection high-pressure hydrothermal reaction kettle, the reaction kettle is heated by microwave, the power is adjusted to 2KW, the temperature in the kettle is raised to 50°C, and the temperature is kept at this temperature for 15min;

[0047] In step (3), a mixed alcohol solution of ethylene glycol, butanetriol, n-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com