HVAC air distribution system

a technology of air distribution system and conditioned air, which is applied in the direction of ventilation system, lighting and heating apparatus, heating type, etc., can solve the problems of increasing the backpressure of the air distribution system, and the current system lacks the ability to sufficiently change the flow parameters of the room, so as to eliminate the temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

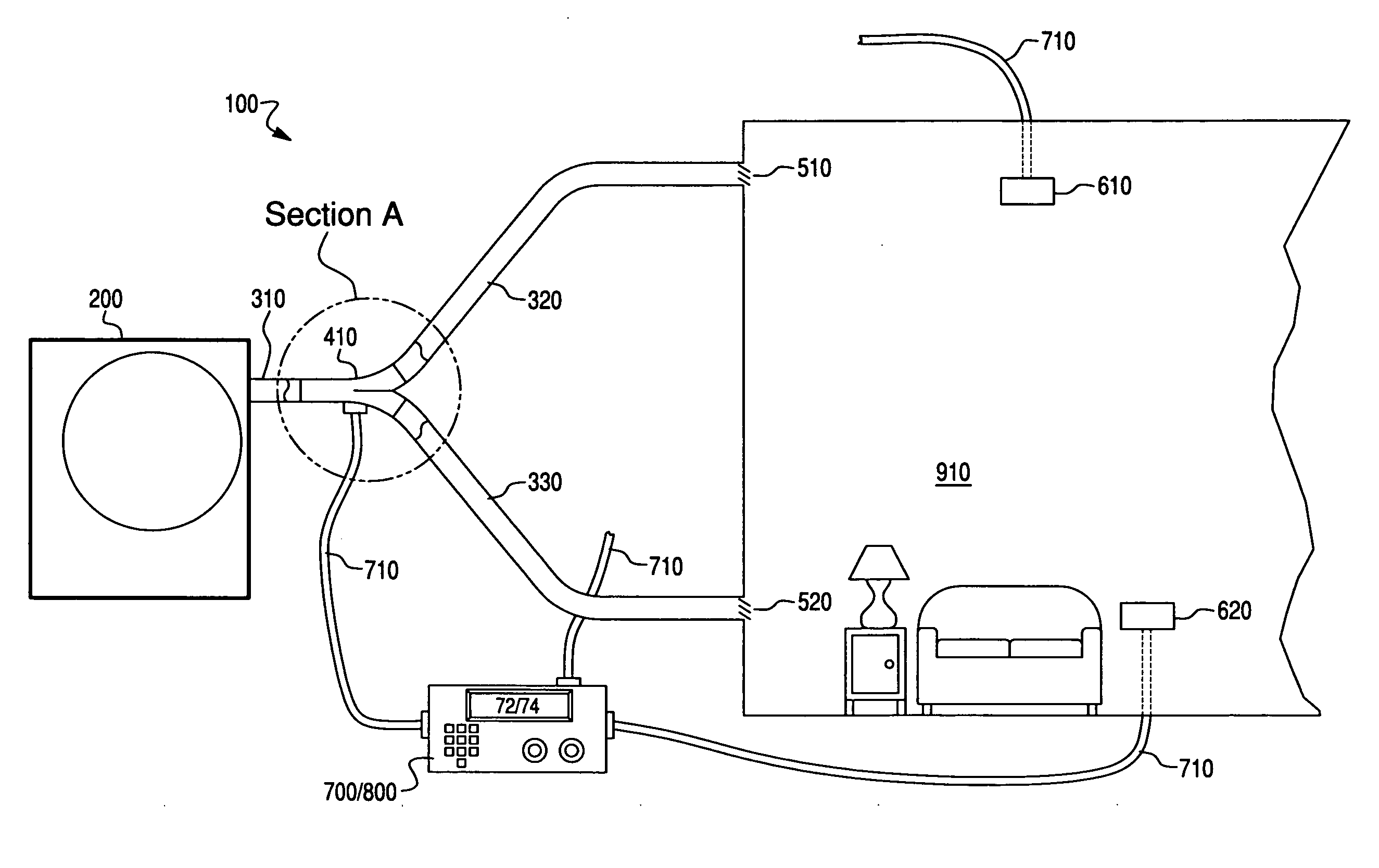

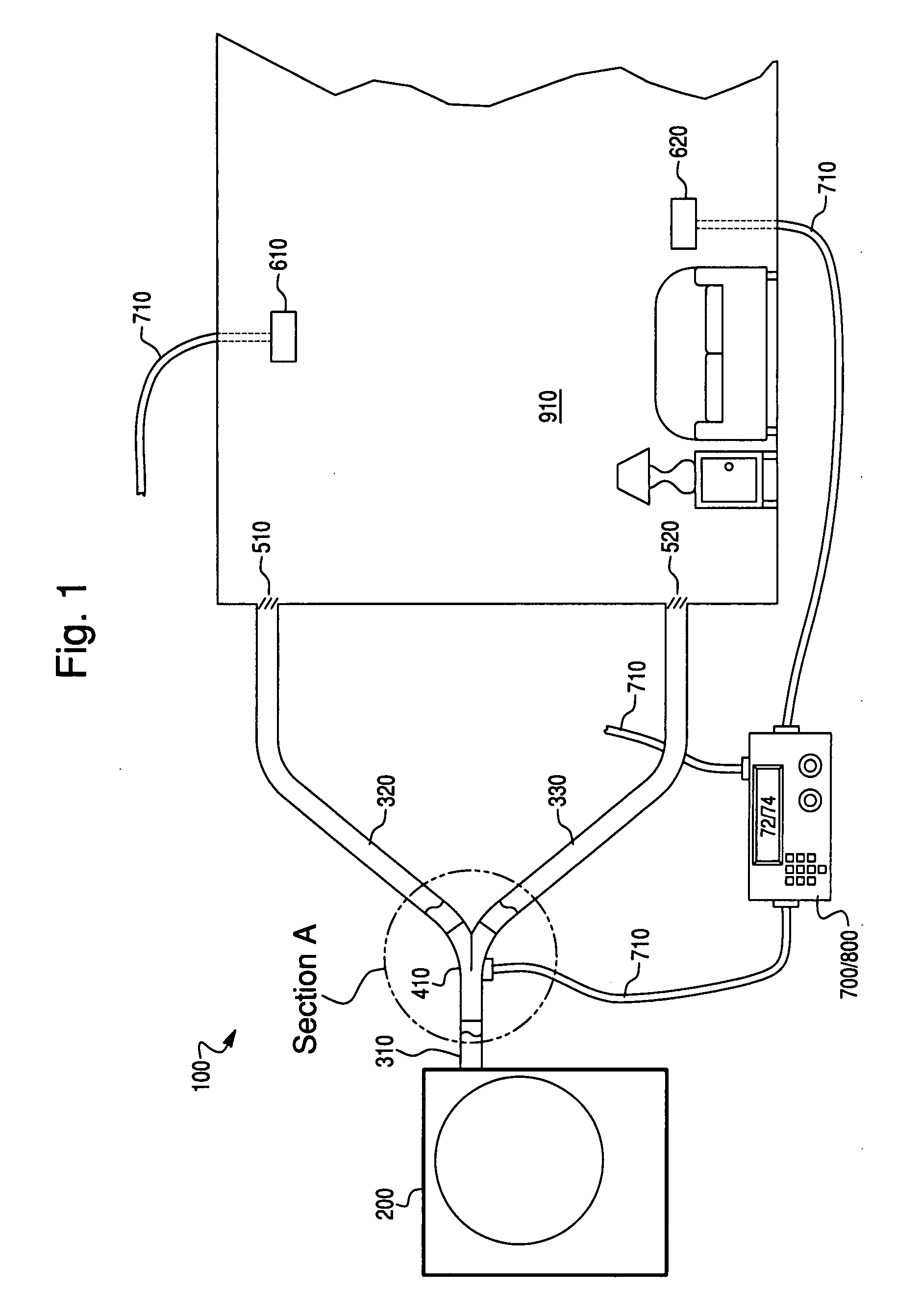

[0016]In a first exemplary embodiment of the present invention, there is a forced-air HVAC system 100 comprising a heater / cooler unit 200 configured to variously heat and cool air (i.e., to output / produce conditioned air). The unit 200 includes a fan or blower (not shown) that generates an airflow out of the unit 200 to move the heated / cooled air through the HVAC system. In some embodiments, the unit 200 may be an integral unit, such as a heat pump, in which one cycle is a cooling cycle and another cycle (a reversed cycle) is a heating cycle. In yet other embodiments, the unit 200 includes a heating element and a separate cooling element such as may be found in a central air system. The HVAC system 100 includes an outlet duct 310 that extends between the heater / cooler unit 200 and a first diverter valve 410.

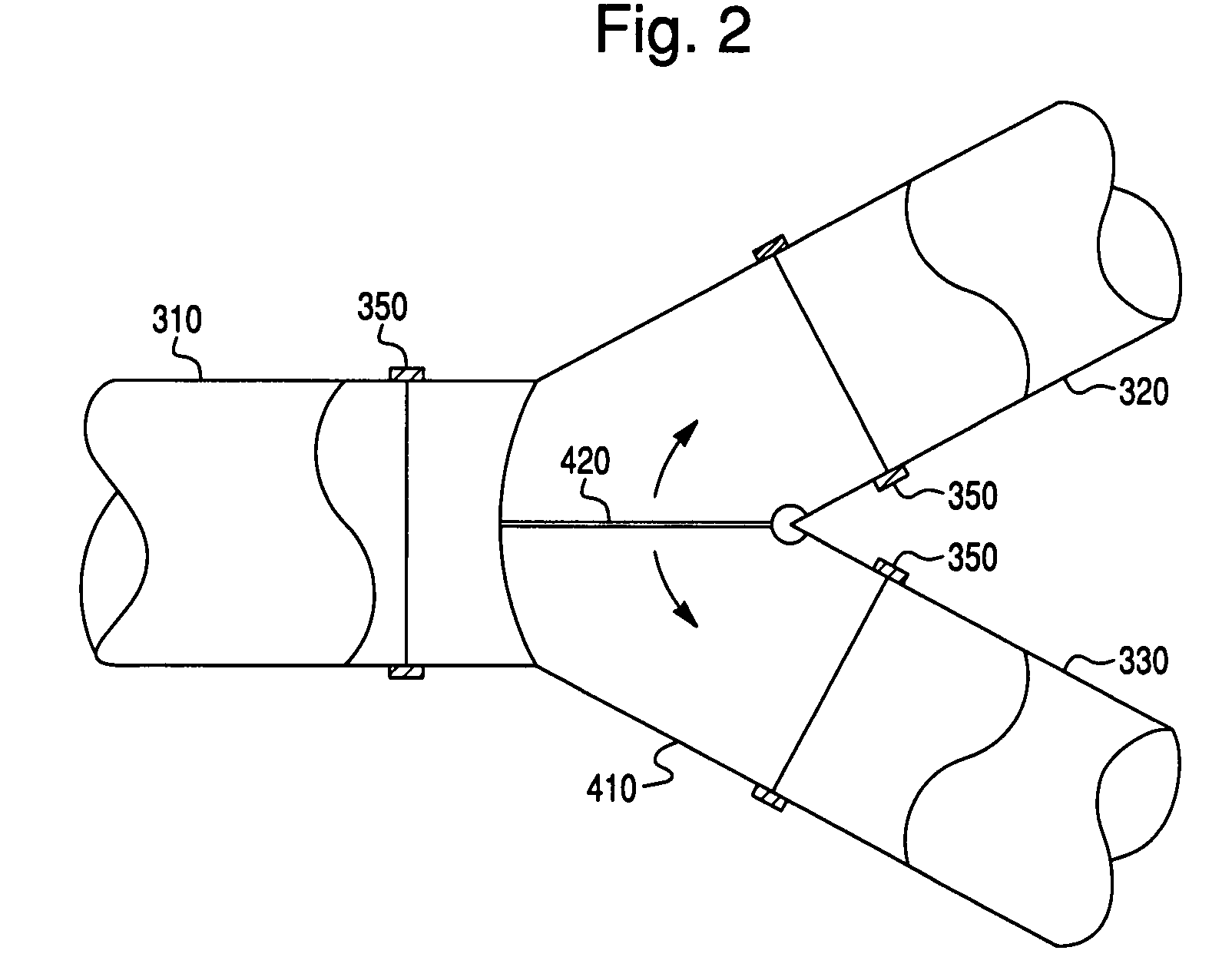

[0017]The diverter valve 410 in the embodiment shown in FIG. 1 is a Y valve, where the valve 410 splits the airflow traveling through duct 310 from heater / cooler unit 200 into tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com