Preparation method and application of pimenta officinalis extract

An allspice fruit and extract technology, applied in the field of flavors and fragrances, can solve the problems of reducing the extraction efficiency of effective components in the allspice fruit, and the effective components are difficult to be extracted, and achieves the advantages of short heating time, fast heating speed, and avoiding structural damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

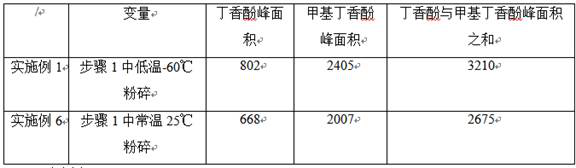

Examples

Embodiment 1

[0041] The present invention provides a kind of method for the preparation of allspice fruit extract, and its steps are as follows:

[0042] Step 1: After washing and drying the dried allspice, perform low-temperature crushing treatment to 200 mesh, set the action temperature of low-temperature crushing to -60°C, and the action time to 2 minutes;

[0043] Step 2: Use 95% ethanol solvent to seal and soak the allspice powder, wherein the solid-liquid ratio of ethanol solvent to allspice powder is 1:5, stir for 30 minutes and then soak for 3 hours;

[0044] Step 3: Place the soaked allspice mixed solution in a microwave extraction device, set the microwave extraction temperature to 15°C, the microwave power to 150W, and the extraction time to 10min, and collect the filtrate A after filtering through a 200-mesh filter cloth;

[0045] Step 4: Put the allspice powder filter residue in step 3 into 50% ethanol solvent, then add graphene oxide and stir evenly, wherein the mass ratio of...

Embodiment 2

[0049] The present invention provides a kind of method for the preparation of allspice fruit extract, and its steps are as follows:

[0050] Step 1: After washing and drying the dried allspice, perform low-temperature crushing treatment to 250 mesh, set the action temperature of low-temperature crushing to -45°C, and the action time to 2.5 minutes;

[0051] Step 2: Use 95% ethanol solvent to seal and soak the allspice powder, wherein the solid-liquid ratio of ethanol solvent to allspice powder is 1:6, stir for 40 minutes and then soak for 4 hours;

[0052] Step 3: Place the soaked allspice mixed solution in a microwave extraction device, set the microwave extraction temperature to 20°C, the microwave power to 200W, and the extraction time to 20min, and collect the filtrate A after filtering through a 200-mesh filter cloth;

[0053] Step 4: Put the allspice powder filter residue in step 3 into 60% ethanol solvent, then add graphene oxide and stir evenly, wherein the mass ratio ...

Embodiment 3

[0057] The present invention provides a kind of method for the preparation of allspice fruit extract, and its steps are as follows:

[0058] Step 1: After washing and drying the dried allspice, carry out low-temperature crushing treatment to 300 mesh, set the action temperature of low-temperature crushing to -30°C, and the action time to 3 minutes;

[0059] Step 2: Use 95% ethanol solvent to seal and soak the allspice powder, wherein the solid-liquid ratio of ethanol solvent to allspice powder is 1:7, stir for 30 minutes and then soak for 5 hours;

[0060] Step 3: Place the soaked allspice mixed solution in a microwave extraction device, set the microwave extraction temperature to 25°C, the microwave power to 250W, and the extraction time to 30min, and collect the filtrate A after filtering through a 200-mesh filter cloth;

[0061] Step 4: Put the allspice powder filter residue in step 3 into 70% ethanol solvent, then add graphene oxide and stir evenly, wherein the mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com