Graphene-based heat conducting piece

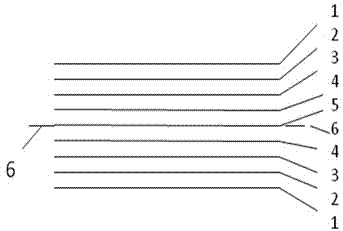

A graphene-based, heat-conducting sheet technology, applied in the direction of cooling/ventilation/heating transformation, layered products, etc., can solve the problems of battery performance stability degradation, power supply and equipment life reduction, combustion, etc., to eliminate temperature gradients, distribution Uniform, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A Cu foil with a thickness of 15 microns was used as the growth substrate. After ultrasonic cleaning with deionized water, ethanol, acetone, and deionized water, it was dried at 60°C and placed in the heating center of the CVD furnace. Using methane as the carbon source and hydrogen as the auxiliary gas, the ratio of methane to hydrogen is 5:1, the growth temperature is 1000°C, the growth time is 30min, the cooling rate is 5min / °C, and the growth pressure is 5000Pa, the obtained graphene for one layer.

[0026] After the graphene-grown copper foil is flattened by a compression molding machine, epoxy resin AB glue is applied to the surface of the copper foil (as a heat-conducting substrate). The coating speed is 30m / min, and the thickness of the heat-conducting glue is 100 microns. Make two slices at the same time. Sprinkle carbon fiber evenly on the surface of one of the thermally conductive adhesives, the coverage of carbon fiber on the adhesive surface is 50%, and th...

Embodiment 2

[0028] The 25-micron copper foil was ultrasonically cleaned with deionized water, ethanol, acetone, and deionized water, and then dried at 60°C. Using nickel with a purity of 99.99% as the target, a layer of nickel is sputtered on the treated copper foil by magnetron sputtering, the sputtering current is 3A, the sputtering time is 30min, and the thickness of the sputtered nickel is 500nm about. Put the copper foil sputtered with a nickel layer into the heating center of a CVD tube furnace, use methane as the carbon source, hydrogen as the auxiliary gas, the ratio of methane and hydrogen is 1:1, the growth temperature is 1020°C, and the growth time is 30min , the temperature was lowered at a cooling rate of 5min / °C, the growth pressure was 10000Pa, and the obtained graphene had 5 layers.

[0029] After the graphene-grown copper foil is flattened by a compression molding machine, epoxy resin AB glue is applied to the surface of the copper foil through a coating machine. The coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com