Welding strip annealing device and annealing method

A technology of annealing device and welding strip, applied in the direction of coating, furnace type, furnace, etc., can solve the problems of insufficient annealing, unstable contact, easy overheating and burnout, etc. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

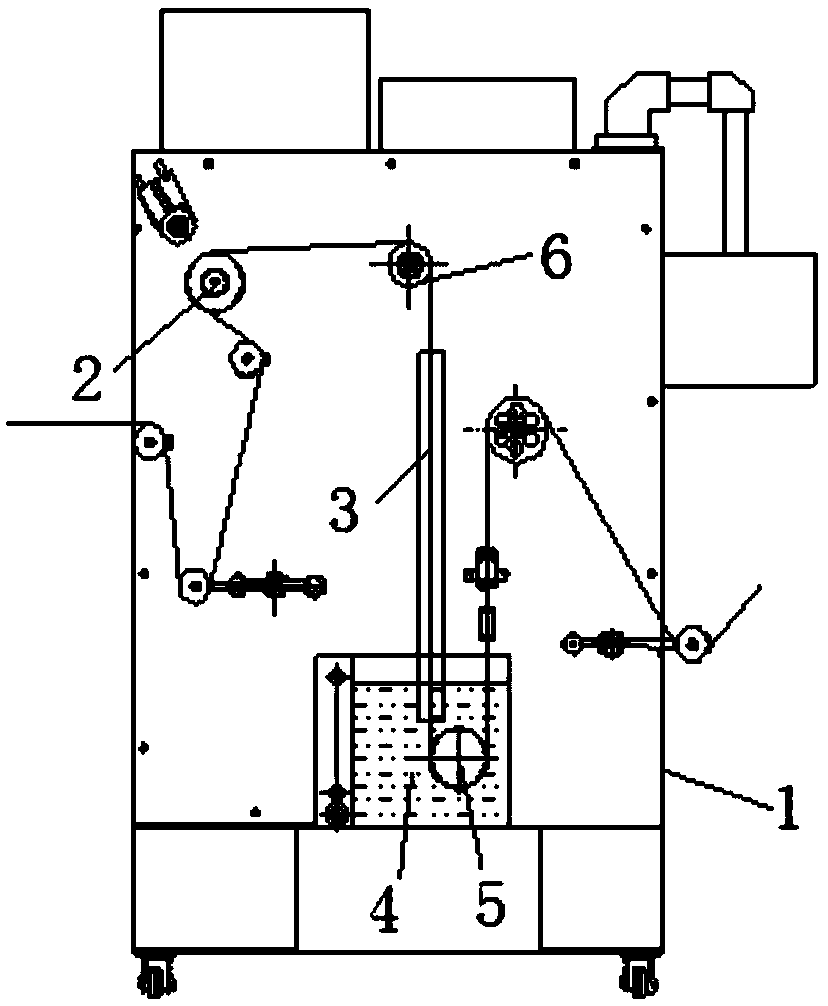

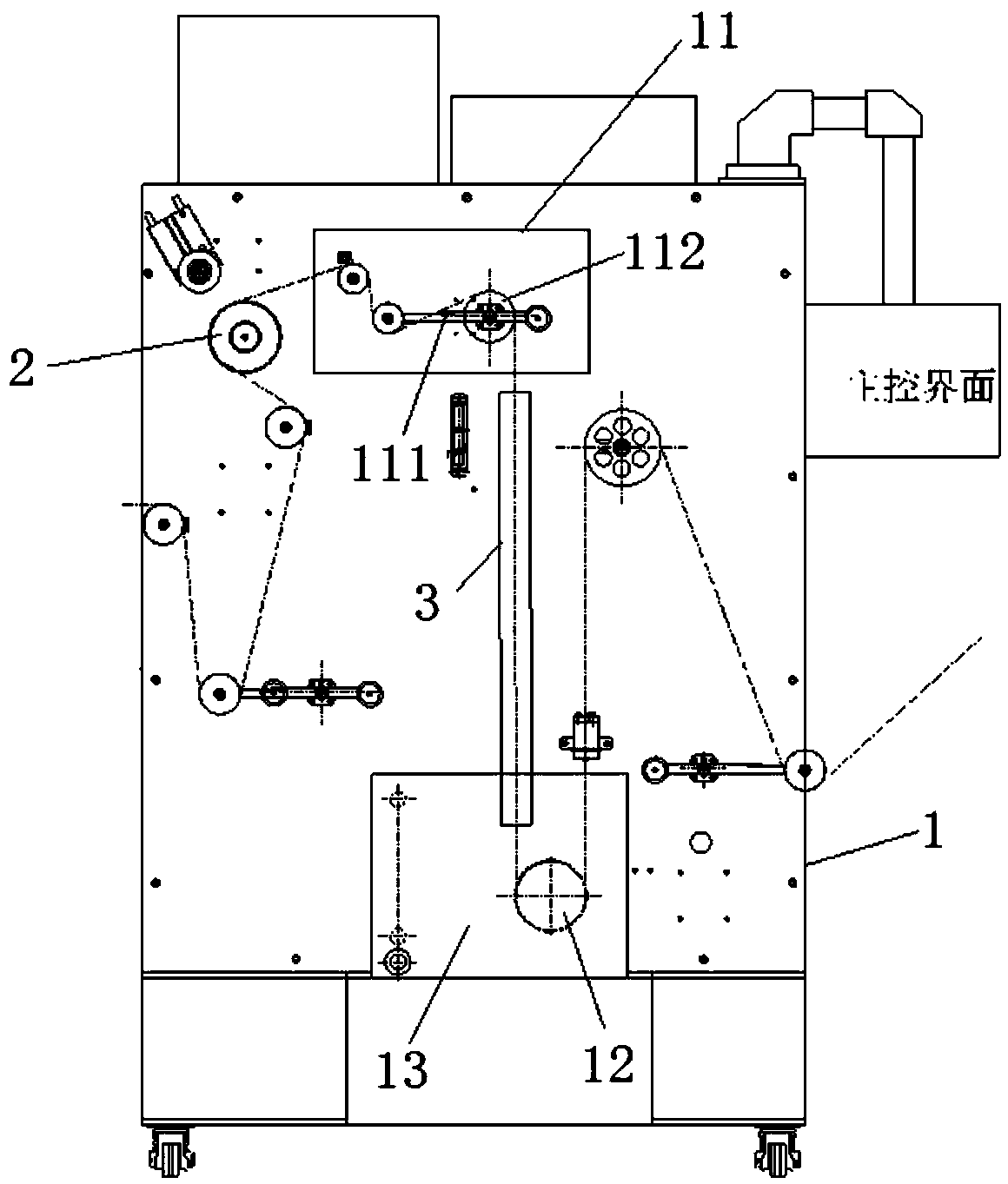

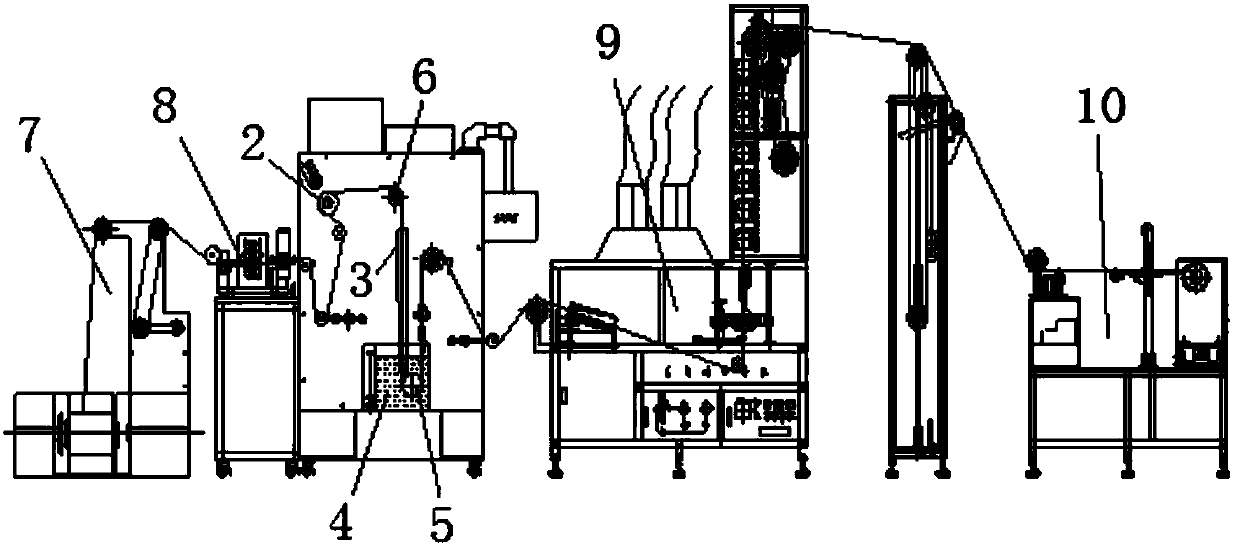

[0030] refer to figure 2 , figure 2 It is a conventional ribbon annealing device, which includes an upper annealing wheel 2 and a lower annealing wheel 12 arranged in a cooling water tank 13. A cycloidal mechanism 11 is arranged between the annealing wheel 2 and the lower annealing wheel 12, and the cycloidal mechanism 11 has a swing lever 111 and a driving wheel 112 in the majority, and the swing lever 111 can adjust the speed of the lower annealing wheel 12. When triangular, circular, embossed, reflective and other welding ribbons and wires adopt conventional welding ribbon annealing devices, because the welding ribbons and wires pass through too many swing bars...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com