Car-type annealing furnace

An annealing furnace and trolley-type technology, which is applied in the field of aluminum plate processing, can solve the problems of low feeding efficiency of the trolley feeding device and poor sealing performance of the furnace door, so as to improve the service life, save manpower and material resources, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

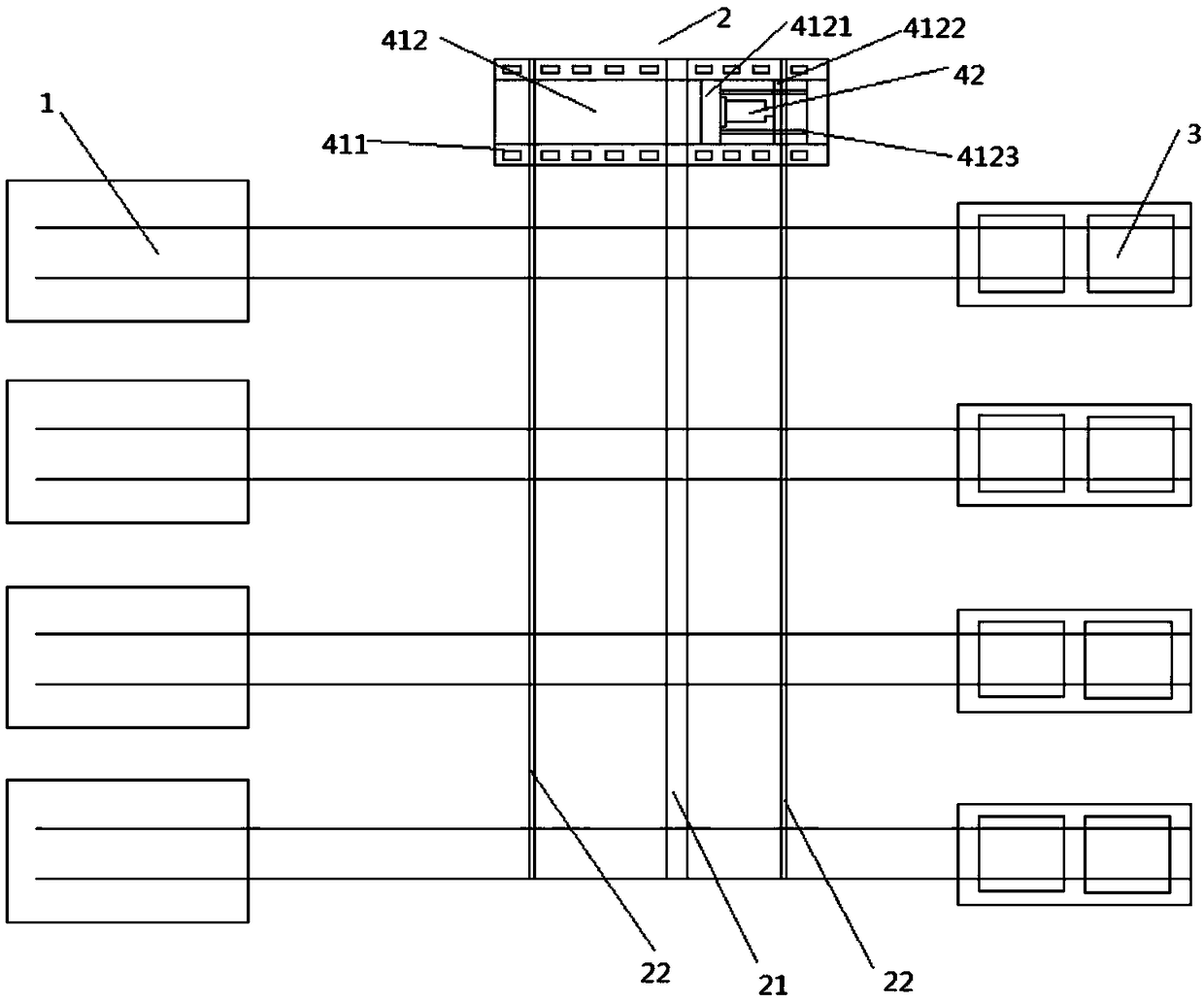

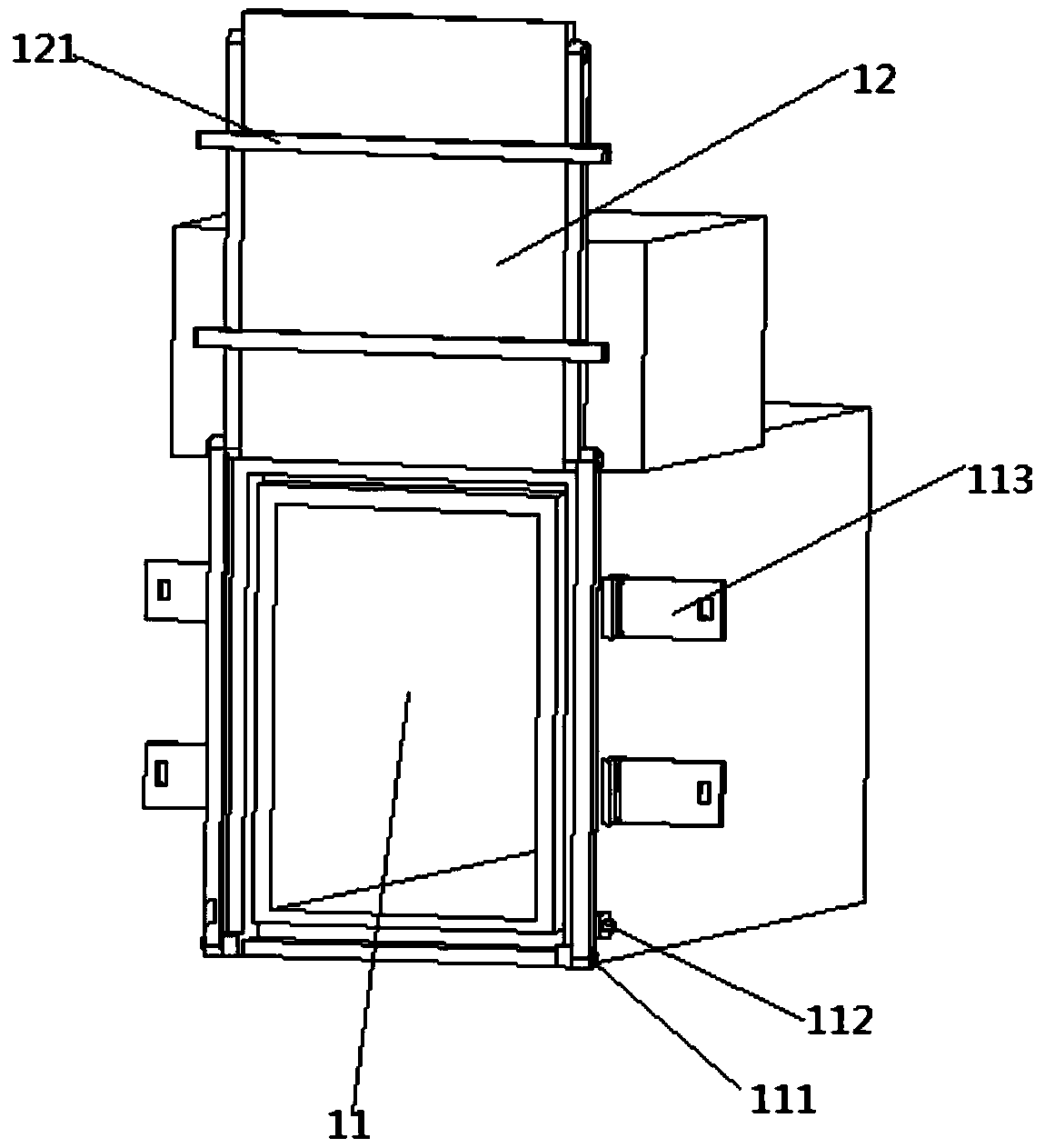

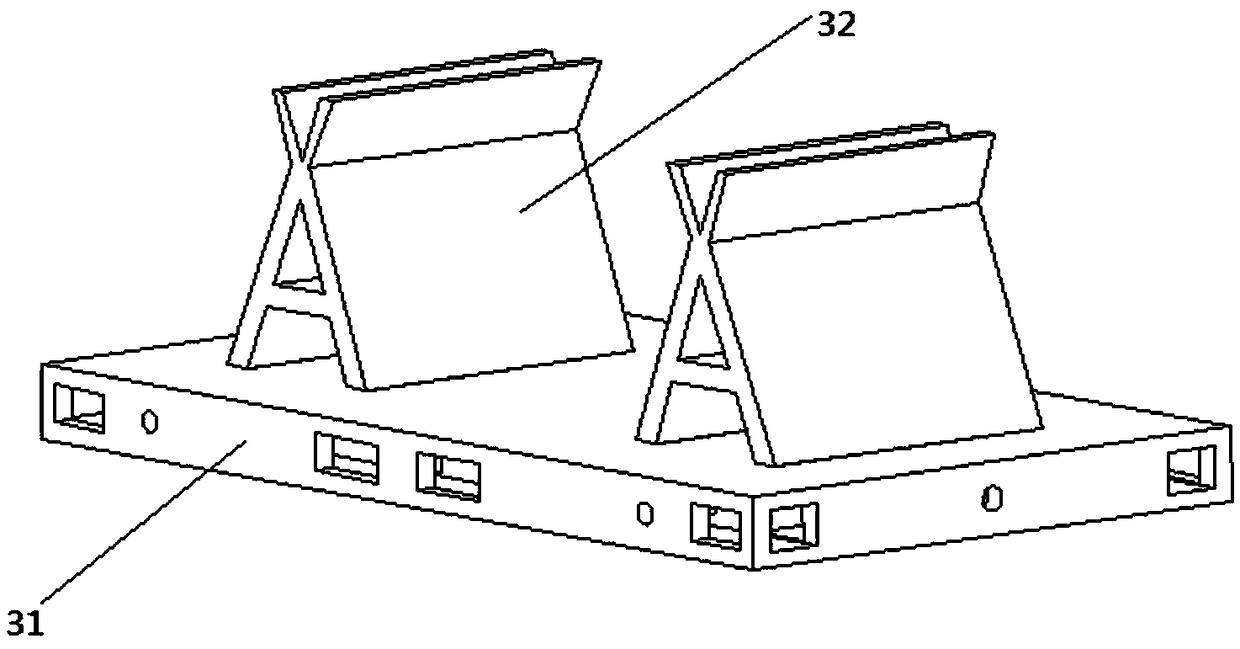

[0031] Such as figure 1Shown: a trolley-type annealing furnace, including an annealing furnace main body 1, a transport track 2, a trolley bracket 3, and a transport trolley 4; the annealing furnace main body 1 includes a furnace body 11 and a furnace door 12, and the transport track 2 includes a limit slot 21. The surface transportation groove 22 and the trolley track 23, the trolley support 3 includes a support bottom plate 31 and an aluminum coil support frame 32 arranged on the support bottom plate 31, and the support bottom plate 31 is movably connected with the aluminum coil support frame 32, and the transport trolley 4 Including a transport frame 41 and a hydraulic pump 42, the annealing furnace main body 1 and the trolley support 3 are placed parallel to each other, and are connected by a trolley rail 23, and the transport trolley 4 is arranged on the surface transport trough between the annealing furnace main body 1 and the trolley support 3 22 and the spacing groove ...

Embodiment 2

[0037] Such as figure 1 Shown: a trolley-type annealing furnace, including an annealing furnace main body 1, a transport track 2, a trolley bracket 3, and a transport trolley 4; the annealing furnace main body 1 includes a furnace body 11 and a furnace door 12, and the transport track 2 includes a limit slot 21. The surface transportation groove 22 and the trolley track 23, the trolley support 3 includes a support bottom plate 31 and an aluminum coil support frame 32 arranged on the support bottom plate 31, and the support bottom plate 31 is movably connected with the aluminum coil support frame 32, and the transport trolley 4 Including a transport frame 41 and a hydraulic pump 42, the annealing furnace main body 1 and the trolley support 3 are placed parallel to each other, and are connected by a trolley rail 23, and the transport trolley 4 is arranged on the surface transport trough between the annealing furnace main body 1 and the trolley support 3 22 and the spacing groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com