Preparation method of high-strength quartz optical fiber

A quartz fiber, high-strength technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problem that the strength of quartz fiber cannot meet the needs of high-strength applications, and achieve the effects of preventing micro-cracks from expanding and increasing, enhancing strength, and eliminating temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is a comparative example. The polished quartz preform in step 2) is directly left to cool down, instead of gradually reducing the heating temperature in step 3) by gradually reducing the hydrogen flow rate in the oxyhydrogen flame.

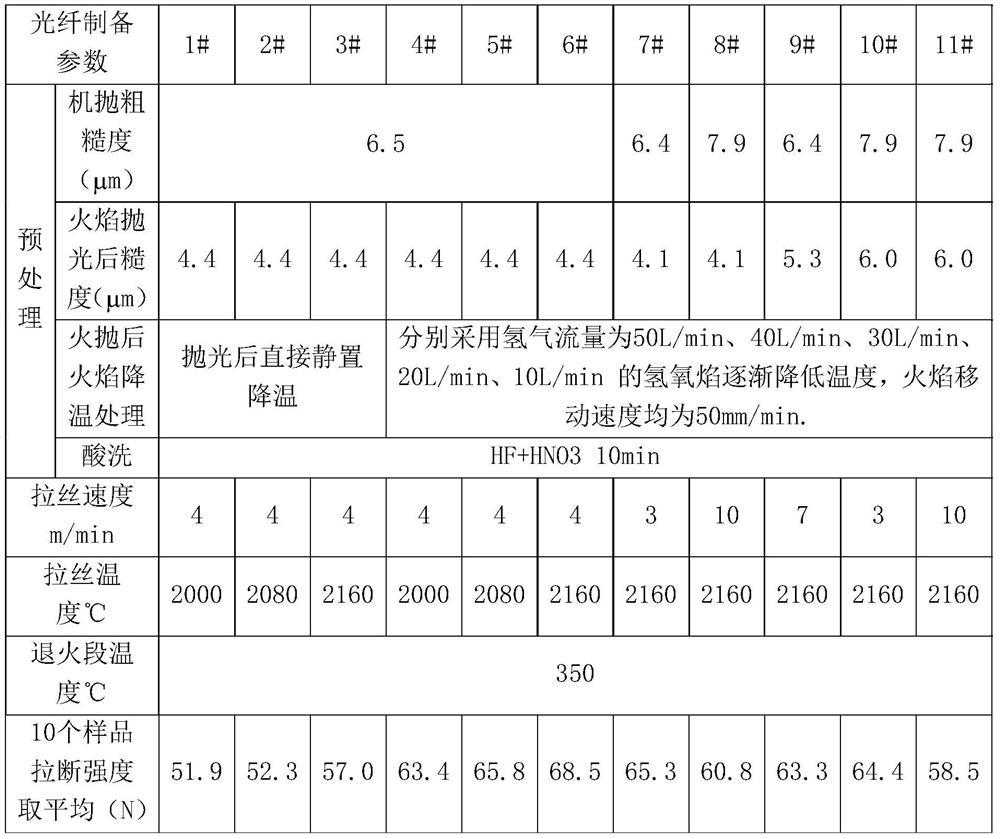

[0028] Using 1 in Table 1 # Parameters Quartz preforms are pretreated and drawn.

[0029] Step 1), select a quartz preform with a diameter of 30 mm, firstly perform mechanical polishing on the quartz preform, the surface roughness of the polished quartz preform is 6.5 μm;

[0030] Step 2), carry out flame polishing to quartz prefabricated rod again, wherein H 2 The flow rate is 80L / min, the flame moving speed is 50mm / min, the number of times is 2 times, and the roughness of the polished quartz preform is 4.4μm;

[0031] Step 3), the quartz preform is directly placed at room temperature;

[0032] Step 4), using HF acid and HNO acid mixed solution to pickle the quartz preform for 10 minutes, and then use deionized water to ...

Embodiment 2

[0037] This embodiment is a comparative example. The polished quartz preform in step 2) is directly left to cool down, instead of gradually reducing the heating temperature in step 3) by gradually reducing the hydrogen flow rate in the oxyhydrogen flame.

[0038] Using 2 in Table 1 # Parameters Quartz preforms are pretreated and drawn.

[0039] The wire-drawing temperature in step 5) in this embodiment is 2080° C., and the rest of the methods are the same as in Embodiment 1.

[0040] After the completion, ten optical fiber samples were selected to test the tensile strength of the optical fiber. The results are shown in Table 1. The average tensile strength of the optical fiber is 52.3N.

Embodiment 3

[0042] This embodiment is a comparative example. The polished quartz preform in step 2) is directly left to cool down, instead of gradually reducing the heating temperature in step 3) by gradually reducing the hydrogen flow rate in the oxyhydrogen flame.

[0043] Using 3 in Table 1 # Parameters Quartz preforms are pretreated and drawn.

[0044] The wire-drawing temperature in step 5) in this embodiment is 2160° C., and the other methods are the same as in embodiment 1.

[0045] After completion, select ten optical fiber samples to test the tensile strength of the optical fiber. The results are shown in Table 1. The average tensile strength of the optical fiber is 57.0N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com