Online process for improving impact toughness of welding heat affected zone

A welding heat-affected zone and impact toughness technology, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of strong restrictions, increased production costs, and high costs, and achieve room or low temperature impact toughness. Increase production Cost, good impact toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An in-line process for improving the impact toughness of welded heat-affected zones. During the welding process of steel, the compressed gas is directly injected at the welding joint 900-1200mm away from the welding arc, and the injection time is 80-120s; the distance between the sprayed welding joint and the welding arc remains unchanged. The welding arc moves forward synchronously.

[0021] The compressed gas is air, the pressure of the compressed gas is 2.5-3.0 MPa, and the flow rate of the compressed gas is 25-30 L / min.

[0022] Among them: the steel is Q550 low-carbon steel, the thickness of the steel plate is 40-60mm; the welding joint is a welding joint formed by manual arc welding, and the welding heat input is 40-50kJ / cm.

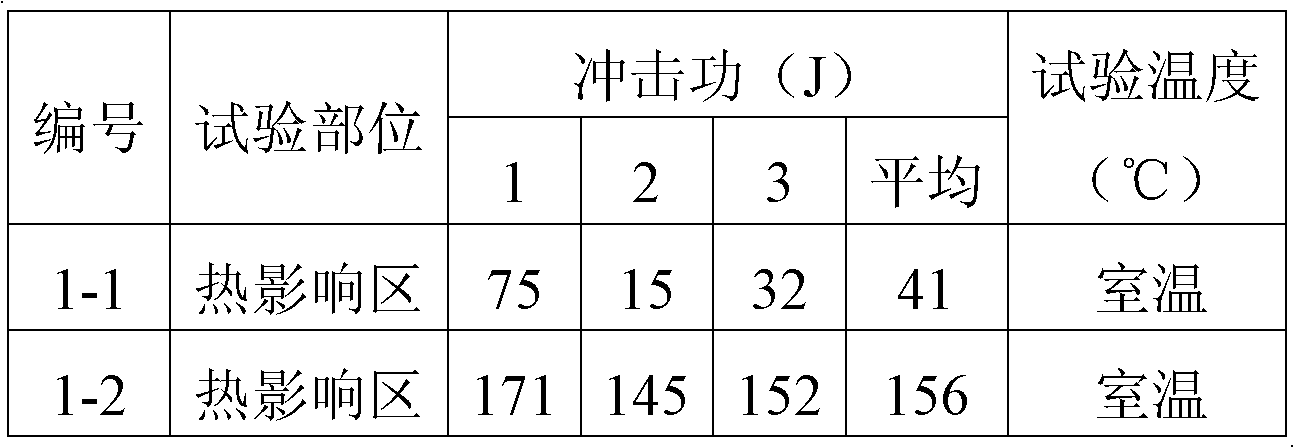

[0023] Table 1 shows the test results of impact toughness at room temperature in the heat-affected zone of this embodiment. Among them, sample 1-2 adopts the process described in this embodiment; sample 1-1 does not use the process describ...

Embodiment 2

[0027] An in-line process for improving the impact toughness of welded heat-affected zones. During the welding process of steel, the compressed gas is directly injected at the welding joint at a distance of 240-600mm from the welding arc, and the injection time is 80-100s; the distance between the sprayed welding joint and the welding arc remains unchanged. The welding arc moves forward synchronously.

[0028] The compressed gas is air, the pressure of the compressed gas is 2.0-2.5MPa, and the flow rate of the compressed gas is 20-25L / min.

[0029] Among them: the steel is Q235 medium carbon steel with a thickness of 20-40mm; the welded joint is a welded joint formed by gas shielded welding, and the welding heat input is 35-40kJ / cm.

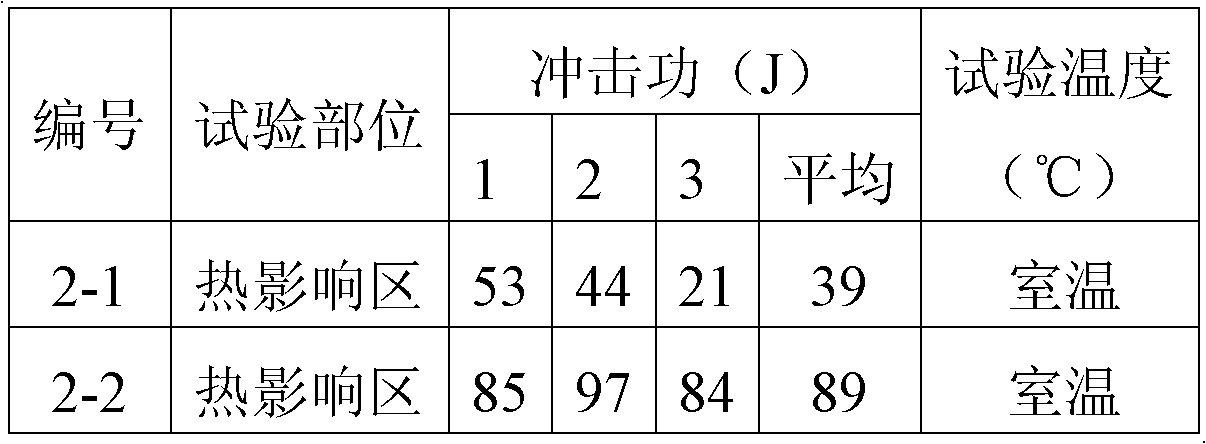

[0030] Table 2 shows the results of the impact toughness test in the heat-affected zone of this embodiment. Among them, sample 2-2 adopts the process described in this embodiment; sample 2-1 does not use the process described in this embodiment...

Embodiment 3

[0034] An in-line process for improving the impact toughness of welded heat-affected zones. During the welding process of steel, the compressed gas is directly injected at the welding joint 600-900mm away from the welding arc, and the injection time is 40-80s; the distance between the sprayed welding joint and the welding arc remains unchanged. The welding arc moves forward synchronously.

[0035] The compressed gas is air, the pressure of the compressed gas is 1.0-2.0 MPa, and the flow rate of the compressed gas is 15-20 L / min.

[0036] The steel in this embodiment is X70 low-alloy steel with a thickness of 15-20 mm; the welded joint is a welded joint formed by submerged arc welding, and the welding heat input is 18-21 kJ / cm.

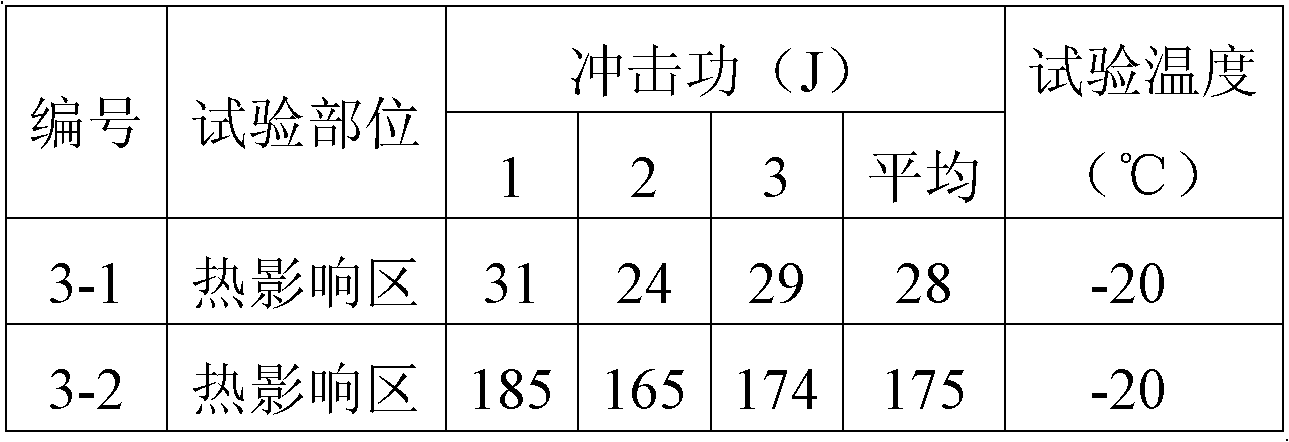

[0037] Table 3 shows the results of the impact toughness test in the heat-affected zone of this embodiment. Among them, sample 3-2 adopts the process described in this embodiment; sample 3-1 does not use the process described in this embodiment. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com