Spring steel and manufacturing and thermal treatment method thereof

A heat treatment method and spring steel technology, applied in temperature control, electric furnace, furnace, etc., can solve the problems of low production efficiency, large thermal stress, increased process and energy consumption, and achieve high production efficiency, strong cold forming ability, and reduced The effect of process and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

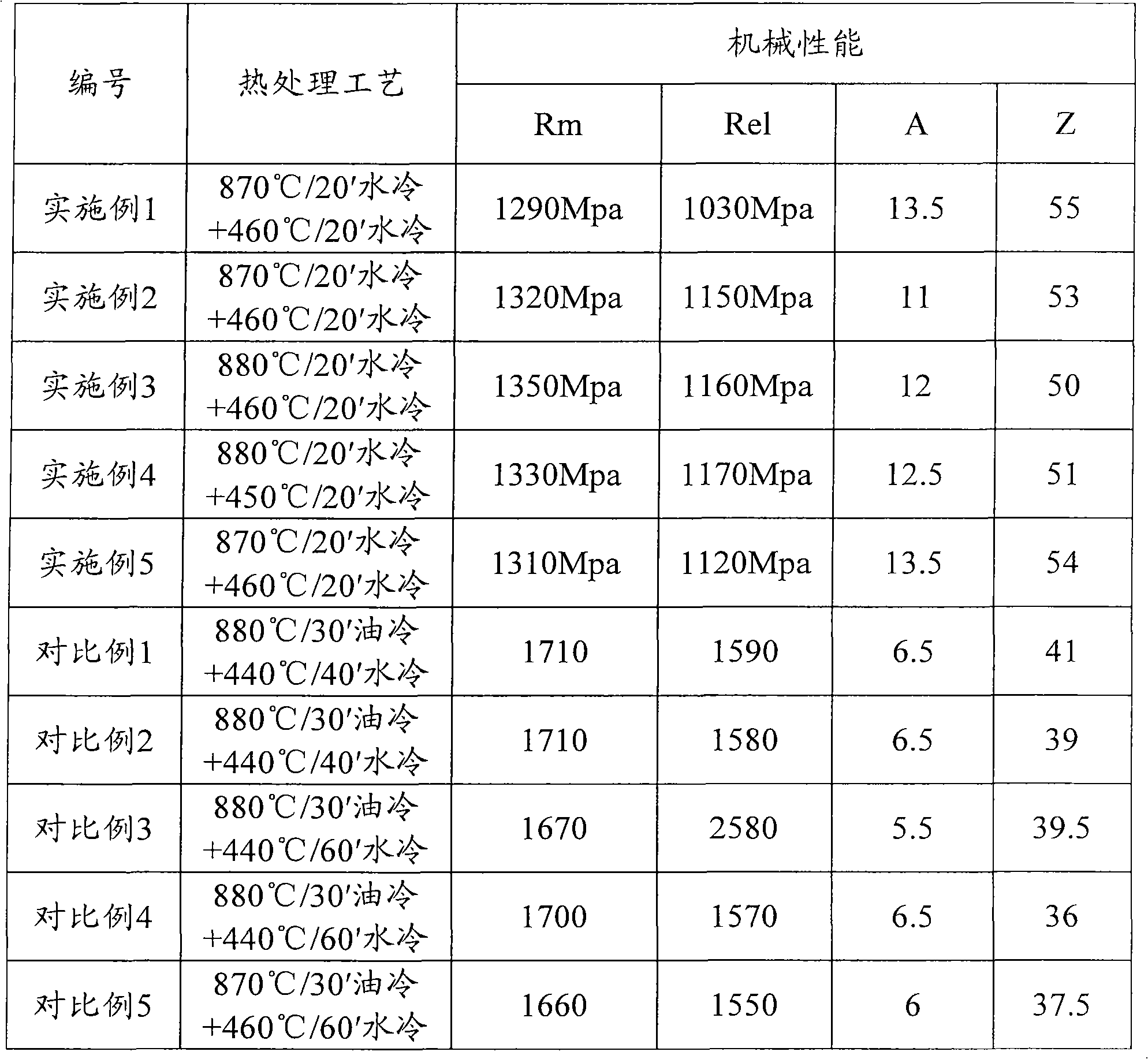

Examples

Embodiment Construction

[0045] The present invention will be described through examples below, and it should be noted that these examples are only exemplary and do not constitute any limitation to the present invention.

[0046] Preparation of spring steel

[0047] The chemical composition of embodiment and comparative example is shown in Table 1, and its preparation process is as follows:

[0048] The first step, electric arc furnace smelting - ladle refining - continuous casting pouring

[0049] Primary smelting of molten steel in a 60-ton electric arc furnace; refining in a 60-ton ladle; continuous casting; production of 90×90mm 2 ~360×360mm 2 Qualified continuous casting slabs with section dimensions:

[0050] (1) Initial smelting: Low P and S scrap steel, cut ends and high-quality pig iron are used as charge materials; low-carbon chromium, low-carbon manganese, etc. should be prepared for alloys; reducing agent: calcium carbide, carbon powder, crystalline silicon, etc.; oxidation period: freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com