Process for preparing synthesis gas by gasifying raw materials with different coal quality characteristics by adopting oxygen-enriched circulating fluidized bed

A circulating fluidized bed and coal gasification technology, applied in the field of coal gasification, can solve problems such as easy slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

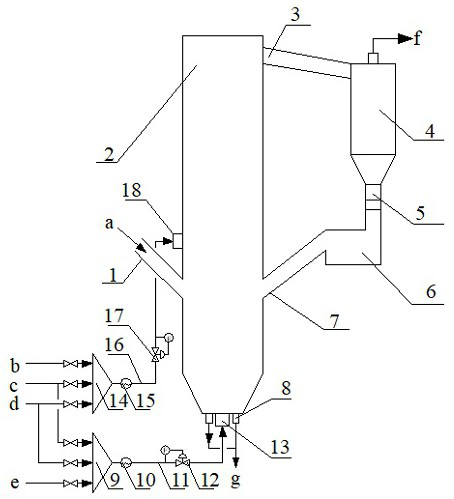

[0032] like figure 1 shown, place 25 o C Oxygen c, 110 o C water vapor d and 25 o C air e is mixed to form a primary oxygen-enriched oxidizing agent with an oxygen concentration of 50 vol.%. After being preheated by the heater, the flow rate is controlled by the flow control valve 12, and the inlet temperature of the primary gasifying agent from the bottom of the gasifier is 900 o In the gasifier around C, a flow field with a gas velocity of 2 m / s is formed in the gasifier. will 25 o C Oxygen c, 110 o C water vapor d and 25 o The carbon dioxide b of C is mixed to form a secondary oxygen-enriched oxidizing agent with an oxygen concentration of 50 vol.%. After being preheated by the heater, the flow rate is controlled by the flow control valve 17. The entry temperature is 900 oIn the gasifier around C. At the same time, the raw coal a is added to the circulating fluidized bed gasifier and reacts with the gasification agent at high temperature to generate crude synthesis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com