Ultrasonic vibration assistance laser boring method and device

A technology of ultrasonic vibration and auxiliary laser, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy adhesion of molten material, affecting the appearance of the inner wall of the hole, cracks, etc., so as to reduce internal defects and avoid disadvantages. Function and influence, the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

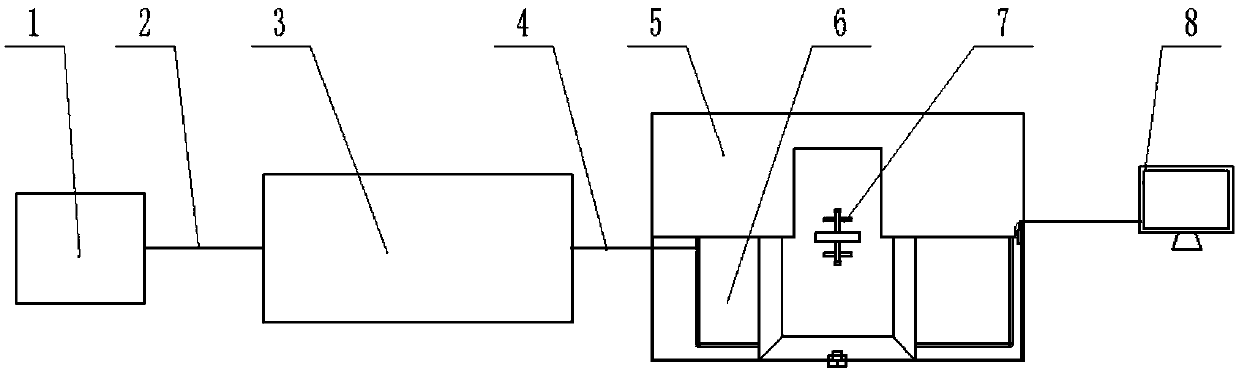

[0045] Such as figure 1 As shown, an ultrasonic vibration assisted laser drilling device according to the present invention includes a power source 1, an ultrasonic generator 3, an ultrasonic vibration auxiliary device clamping unit 5, an ultrasonic vibration generating unit 6, a workpiece clamping unit 7, and a water depth detection The unit 8 and the laser generating unit, the power supply 1 is connected to the ultrasonic generator 3 through the first wire 2, the ultrasonic generator 3 is connected to the ultrasonic vibration generating unit 6 through the second wire 4, the ultrasonic generator 3 and the ultrasonic vibration generating unit 6 generate The ultrasonic power can be adjusted.

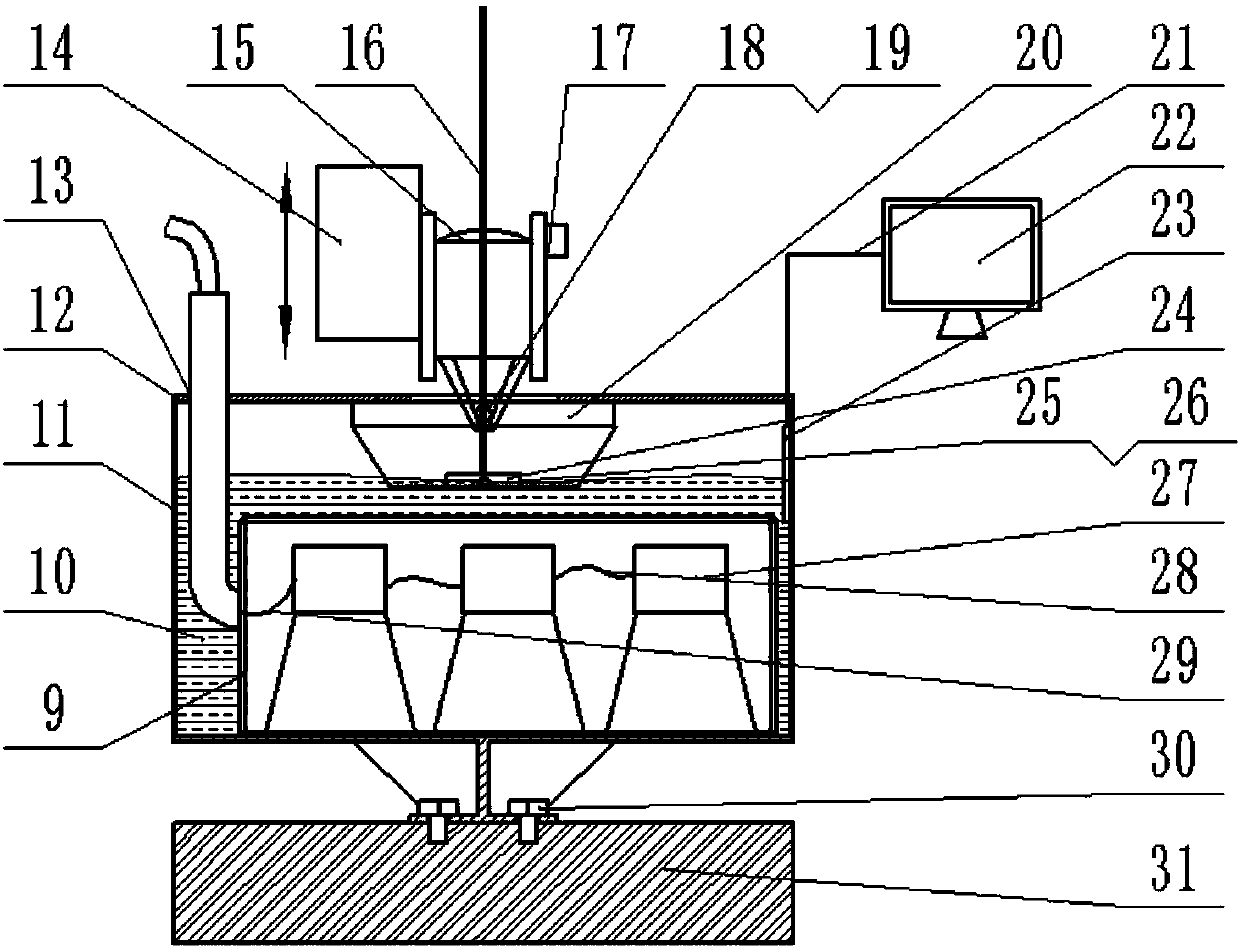

[0046] Such as figure 2 As shown, the function of the ultrasonic vibration generating unit 6 is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com