A method of manufacturing an optical fiber preform and its manufacturing equipment

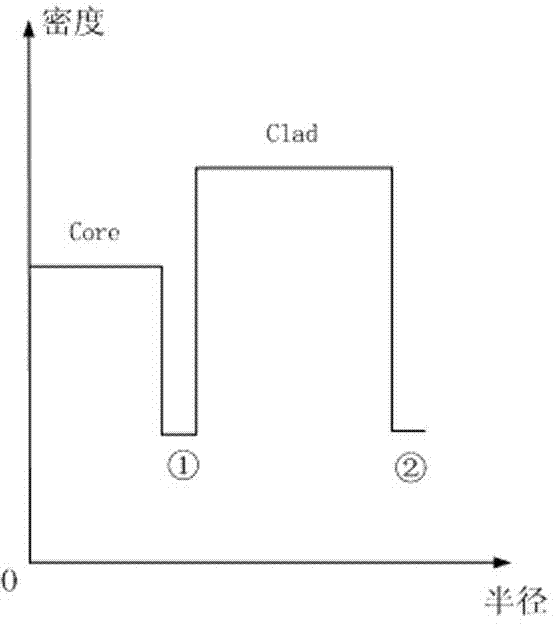

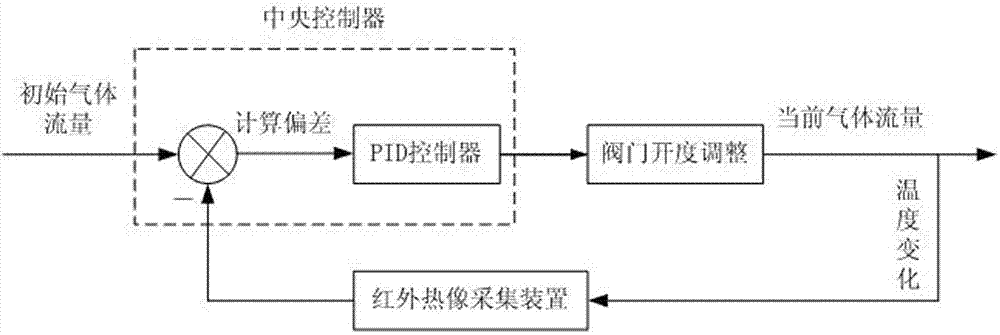

A technology for optical fiber preform and manufacturing equipment, which is applied to the manufacturing method of optical fiber preform and its manufacturing equipment involves the field of optical fiber preform manufacturing, which can solve the problems of inability to adjust the gas flow rate in real time, achieve product quality improvement, reasonable design, and prevent density The effect of a significant change in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

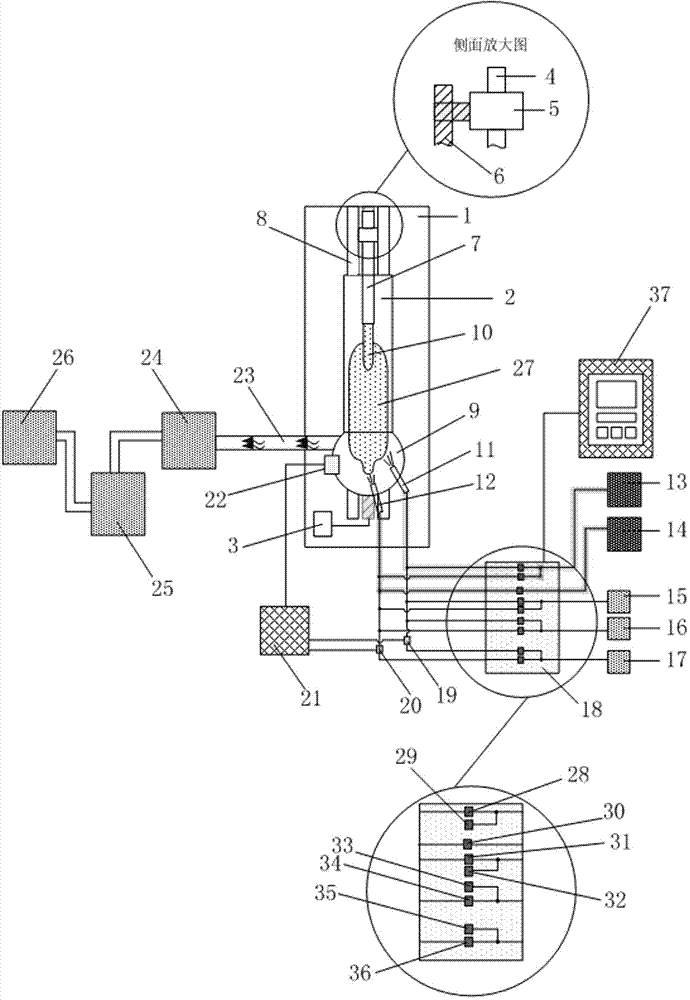

[0066] A quartz target rod 10 with a length of 500 mm is installed on the metal suspender 7, and the SiCl with an initial flow rate of 0.1 g / min 4 , 0.01g / min of GeCl 4 , Ar at 1.0L / min, O at 5.0L / min 2 and 3.0L / min of H 2 Pass into the quartz blowtorch 212 to generate SiO through flame hydrolysis reaction 2 、GeO 2, attached to the lower end of the quartz target rod 10 to form a core layer. Feed SiCl with an initial flow rate of 0.1 g / min into the quartz blowtorch 11 4 , Ar at 1.0L / min, O at 15.0L / min 2 and 10.0L / min of H 2 , to generate SiO by flame hydrolysis 2 , forming the cladding of the preform. The flow settings of each stage are as follows in Table 1:

[0067]

[0068] Table 1

[0069] Such as figure 2 , the rotation of the metal boom 7 is controlled by the chuck 5, and the metal boom 7 pulls the quartz target rod 10 up along the guide rail 8, wherein the rotation speed is controlled at 10rpm, and the lifting speed is controlled at 35mm / h. The internal...

Embodiment 2

[0073] A quartz target rod 10 with a length of 500 mm is installed on the metal suspender 7, and the SiCl with an initial flow rate of 0.1 g / min 4 , 0.01g / min of GeCl 4 , Ar at 1.0L / min, O at 6.0L / min 2 and 4.0L / min of H 2 Pass into the quartz blowtorch 212 to generate SiO through flame hydrolysis reaction 2 、GeO 2 , attached to the lower end of the quartz target rod 10 to form a core layer. Introduce SiCl with an initial flow rate of 0.1g / min into the quartz blowtorch-11 4 , Ar at 1.0L / min, O at 20.0L / min 2 and 15.0L / min of H 2 , to generate SiO by flame hydrolysis 2 , forming the cladding of the preform. The flow setting of each stage is as follows in Table 2:

[0074]

[0075] Table 2

[0076] Such as figure 2 , the rotation of the metal boom 7 is controlled by the chuck 5, and the metal boom 7 pulls the quartz target rod 10 up along the guide rail 8, wherein the rotation speed is controlled at 10rpm, and the lifting speed is controlled at 35mm / h. The inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com