Heat-treating method and device for nanocrystalline alloy strip

A technology of nanocrystalline alloys and heat treatment methods, applied in heat treatment baths, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of no effective methods and equipment, failure to achieve prefabricated crystal nuclei, slow heating and cooling speeds, etc., to achieve convenient Control heat treatment time, facilitate heat treatment time, control the effect of heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

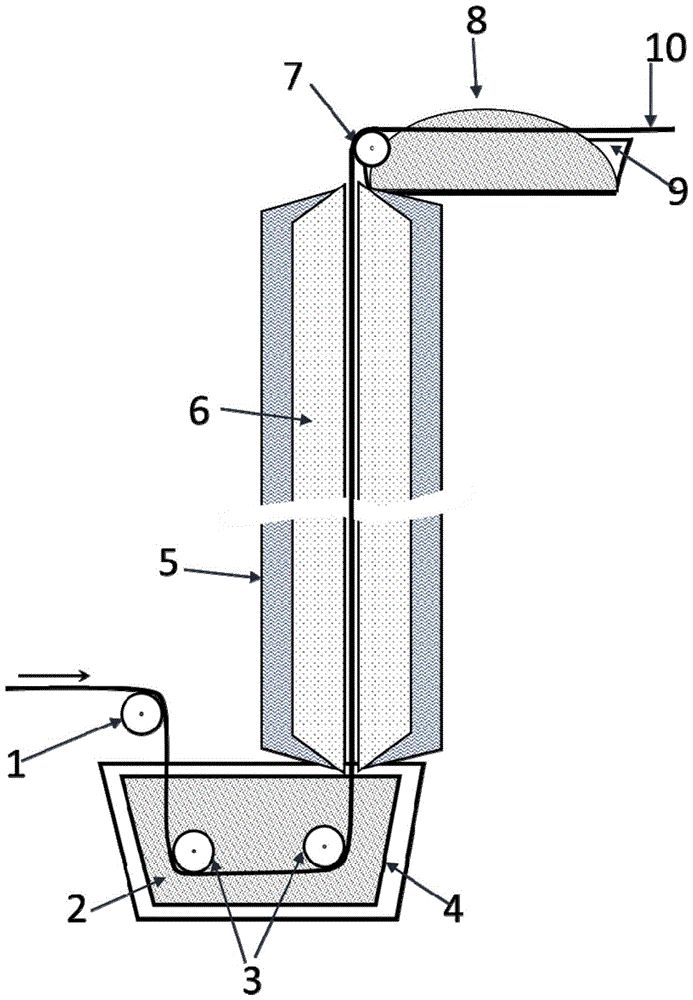

[0041] In order to achieve rapid heating and rapid cooling in one heat treatment process, to achieve the purpose of surface passivation treatment and prefabricated crystal nuclei, this embodiment adopts salt bath soft contact to realize rapid heating and surface passivation, and uses a constant temperature unit to realize possible prefabrication of crystal nuclei. Controlled operation, using the characteristics of good toughness of the strip after short-time heat treatment, designed the heat treatment device

[0042] Such as figure 1 As shown, the heat treatment device of the nanocrystalline alloy strip of the present embodiment includes: a pulley guide roller 1, a salt bath 4, a salt bath 2, two guide rollers 3 arranged at the bottom of the bath salt pool 4, a heat preservation cover 5, a heating Assembly 6, cooling guide roller 7, cooling pool 9, cooling powder 8 and take-up wheel (not shown in the figure). In order to rapidly heat the strip in the salt bath 4, it can quick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com