Mold and method for pressing brick tea

A technology for pressing molds and brick tea, applied in the field of brick tea processing, can solve the problems of inaccuracy, failure to meet the density requirements of brick tea, different density of brick tea, etc., and achieve the effect of precise density control and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

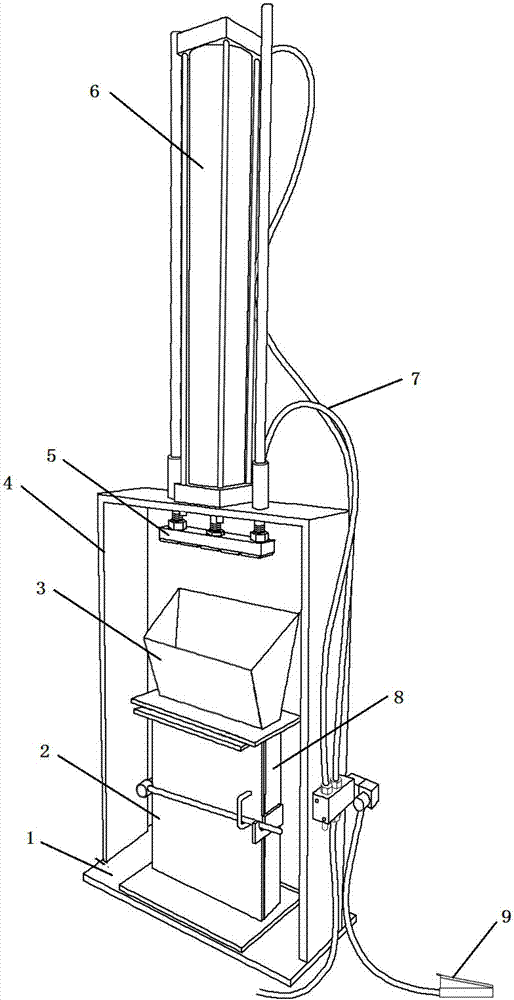

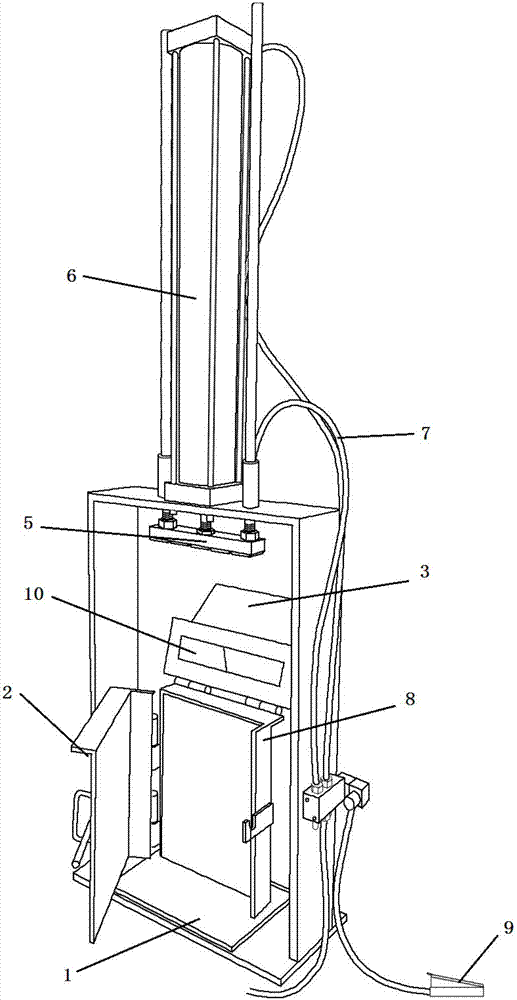

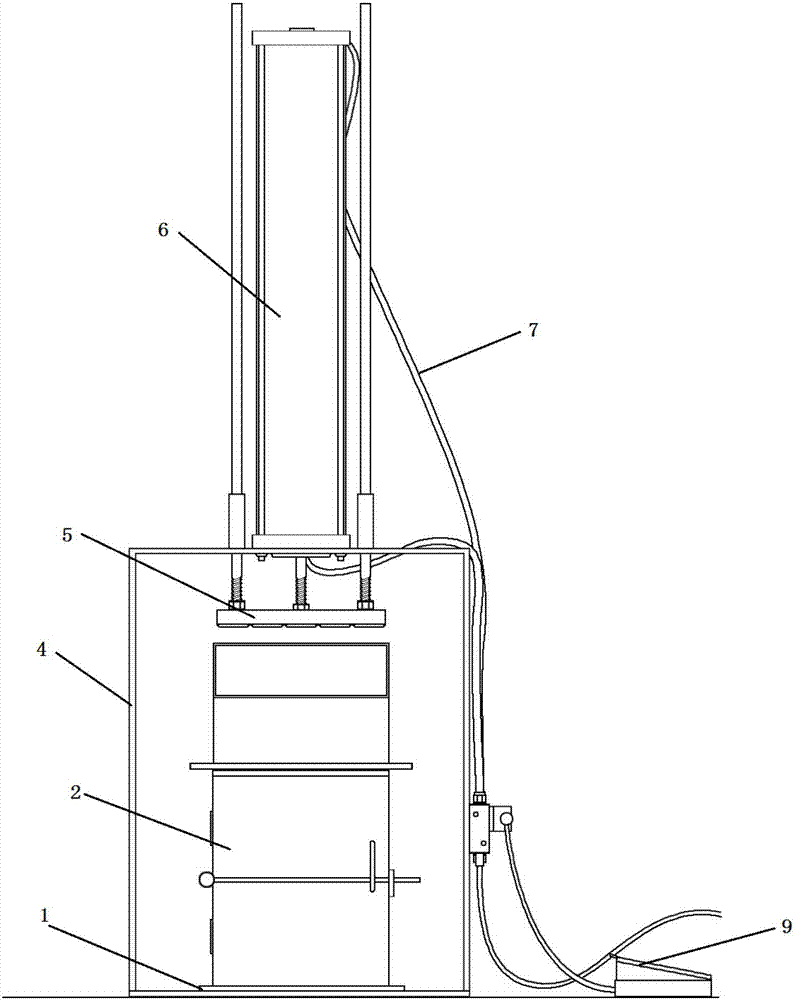

[0025] like figure 1 As shown, this embodiment provides a brick tea pressing mold, including: a base 1 , a brick mold body 8 , a movable plate 2 , and a feed port 10 .

[0026] The base 1 is used to provide support for the pressing of brick tea. In this embodiment, a square aluminum plate is used, and the upper and lower surfaces of the square aluminum plate are flat.

[0027] The brick-shaped mold body 8 is arranged above the base 1, and is used to provide processing space for the pressing and forming of brick tea.

[0028] The movable plate 2 is detachably connected to one side of the brick mold body 8, and is used for opening and closing the brick mold body 8 to take out the pressed brick tea.

[0029] In the traditional brick tea pressing process, the brick tea is generally pressed first and then packaged into a special tea bag. This not only adds additional procedures, but also easily causes subsequent pollution or damage to the brick tea. The present invention is equi...

Embodiment 2

[0037] In order to better control the air pressure plate, this embodiment adds a foot-operated air pressure switch 9 on the basis of Embodiment 1, which is used to control the cylinder 6 to provide power for the air pressure plate 5 .

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 is that the end surface of the air pressure plate 5 in contact with the brick tea raw material is provided with a plurality of grooves at intervals, so that when the brick tea is pressed in layers, each layer of brick tea is tightly occluded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com