Supercritical water oxidation industrial salt elimination method and system

A supercritical water oxidation and supercritical technology, applied in chemical instruments and methods, separation methods, oxidized water/sewage treatment, etc., can solve the problem of difficulty in maintaining high pressure in the reaction system, high economic cost, and wear of the sealing surface of the back pressure valve, etc. problems, to achieve the effect of continuous salt discharge, reduce investment and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

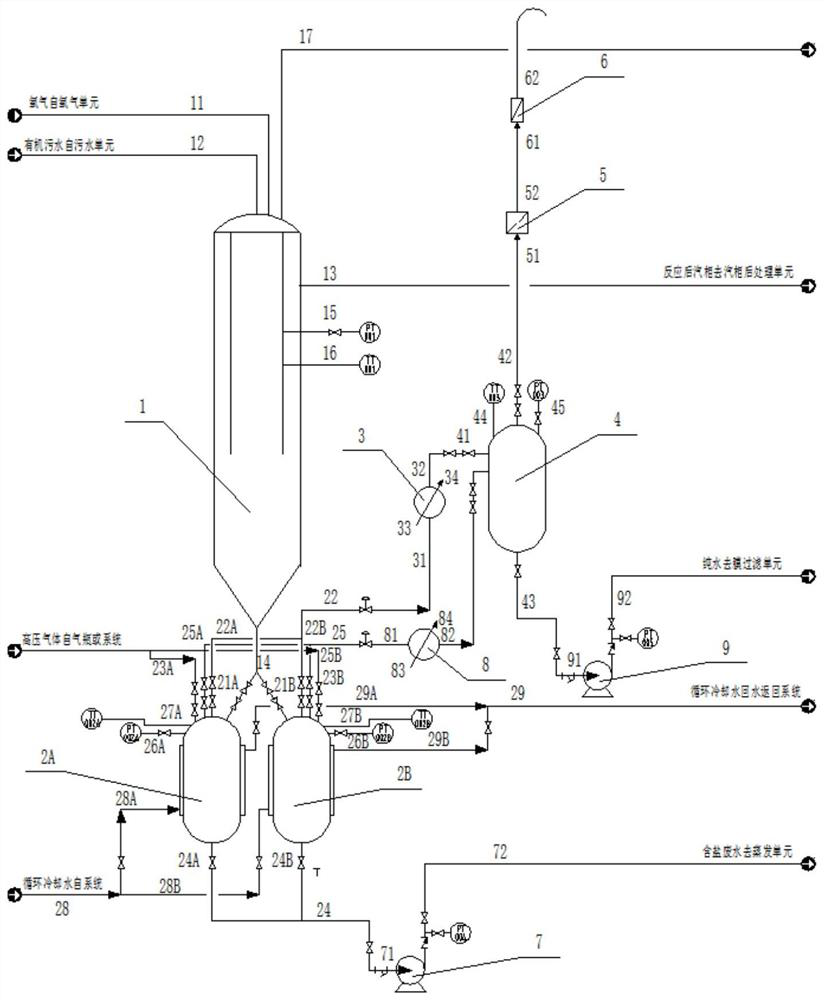

[0042] like figure 1 Shown is the process flow chart of the salt discharge system in the technical field of supercritical water oxidation treatment of sewage such as organic solid waste, organic hazardous waste and radioactive organic waste, wherein the salt discharge system includes supercritical water oxidation reactor 1, lock bucket 2A / B , Water cooler 3, vapor-liquid separator 4, precision filter 5, muffler 6, salt liquid pump 7, water cooler 8, pure water pump 9 and its pipes and valves.

[0043]The supercritical water oxidation reactor 1 is provided with a plurality of inlet pipes, outlet pipes and temperature and pressure monitoring points, an oxygen inlet 11, an organic sewage inlet 12, a post-reaction vapor phase outlet 13, a post-reaction salt discharge outlet 14, and a reactor pressure measurement 15 , reactor temperature measurement 16 , emergency vent 17 . The organic sewage that reaches the supercritical condition enters the reactor through the organic sewage in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com