Method for synthesizing 2, 6-di-tert-butylphenol by using environment-friendly heterogeneous catalyst

A technology of di-tert-butylphenol and heterogeneous catalysts, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as complex operation, unstable pressure, and difficult separation. Achieve the effects of simple preparation process, stable reaction pressure, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

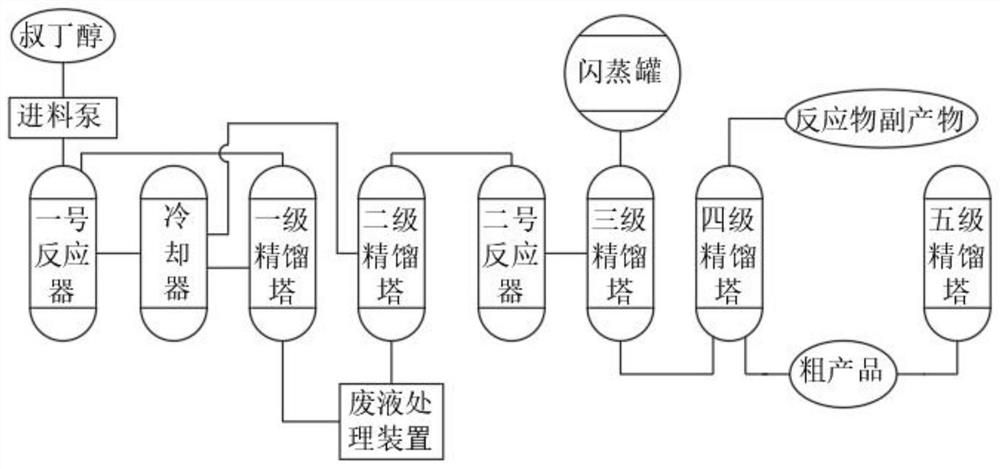

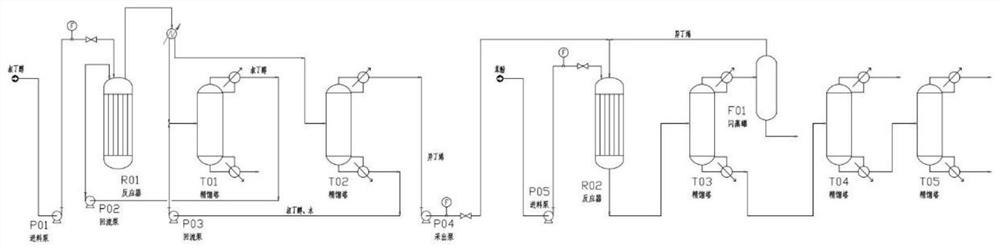

[0043] Such as figure 2 In the process flow shown, take 4kg CD650 resin catalyst and spread it in the No. 1 reactor. The raw material of tert-butanol enters the No. 1 reactor and heats up to 100°C. After catalysis, the reacted liquid enters the cooler and cools The liquid enters the first-stage packing rectification tower, the height of the first-stage packing rectification tower is about 2.5m, the tower diameter is 0.2m, the reflux ratio is 3, the main packing is Raschig ring, and the tert-butanol from the top of the tower is refluxed into No. reactor. The gaseous state in the cooler enters the secondary packing rectification tower, the height of the secondary packing rectification tower is about 2m, the tower diameter is 0.2m, the reflux ratio is 3, the main packing is Raschig ring, and the isobutene product comes out from the top of the tower, the purity reaches 99.99%; about 5kg of ZGC-111 resin solid acid catalyst is laid in the fixed bed reactor, and the isobutene and ...

Embodiment 2

[0045] Such as figure 2 In the process flow shown, take 4kg CD650 resin catalyst and spread it in the No. 1 reactor. The raw material of tert-butanol enters the No. 1 reactor and heats up to 100°C. After catalysis, the reacted liquid enters the cooler and cools The liquid enters the first-stage packing rectification tower, the height of the first-stage packing rectification tower is about 2.5m, the tower diameter is 0.2m, the reflux ratio is 3, the main packing is Raschig ring, and the tert-butanol from the top of the tower is refluxed into No. reactor. The gaseous state in the cooler enters the secondary packing rectification tower, the height of the secondary packing rectification tower is about 2m, the tower diameter is 0.2m, the reflux ratio is 3, the main packing is Raschig ring, and the isobutene product comes out from the top of the tower, the purity reaches 99.99%; about 5kg of CS-N-001 solid acid catalyst is laid in the fixed bed reactor, and the isobutene and pheno...

Embodiment 3

[0047] Such as figure 2In the process flow shown, take 4kg CD550 type resin catalyst and lay it in the No. 1 reactor. The tert-butanol raw material enters the No. 1 reactor. After catalysis, the reacted reaction liquid enters the cooler, and the cooling liquid enters the primary packing. In the rectification tower, the height of the primary packing rectification tower is about 2.5m, the tower diameter is 0.2m, the reflux ratio is 3, the main filler is Raschig ring, and the tert-butanol is refluxed into the No. 1 reactor from the top of the tower. The gaseous state in the cooler enters the secondary packing rectification tower, the height of the secondary packing rectification tower is about 2m, the tower diameter is 0.2m, the reflux ratio is 3, the main packing is Raschig ring, and the isobutene product comes out from the top of the tower, the purity reaches 99.99%; about 5kg of CS-001 resin solid acid catalyst is laid in the fixed bed reactor, and the isobutene and phenol de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com