Method for removing calcium and magnesium ions in manganese sulfate solution by low temperature crystallization

A technology of manganese sulfate solution and calcium and magnesium ions, which is applied in the direction of manganese sulfate, etc., can solve the problems of single production process, high production cost, and low product purity, so as to simplify the process flow, reduce energy and water consumption, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 100mL of manganese sulfate solution leached from manganese ore into the reaction vessel, then add 1M sulfuric acid to adjust the acidity to pH 2;

[0028] Next, 100 mL of absolute ethanol was added, and the mixed solution was stirred (temperature 25°C, speed 100 rpm, time 2 hours), and after the precipitation of manganese sulfate crystals was completed, stand at room temperature for 1 hour;

[0029] Filter and separate the precipitated manganese sulfate crystals from the solution, use the filtrate for later use, and dry the manganese sulfate crystals in an oven (at a temperature of 40°C for 12 hours) to obtain high-purity manganese sulfate crystals.

[0030] Distill the filtrate of step to separate the organic solvent therefrom for recycling.

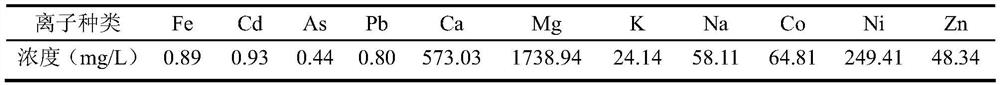

[0031] This example manganese sulfate solution is obtained from Chongzuo Branch of CITIC Dameng Mining Co., Ltd. by sulfuric acid leaching manganese ore, wherein the content of manganese is 130g / L, and other ion concentra...

Embodiment 2

[0035] Add 100mL of manganese sulfate solution leached from manganese ore into the reaction vessel, then add 1M hydrochloric acid to adjust the acidity to pH 1;

[0036] Then add 300 mL of propanol, stir the mixed solution (temperature 30°C, speed 150 rpm, time 0.1 hour), after the precipitation of manganese sulfate crystals is complete, let stand at room temperature for 2 hours;

[0037] Filter and separate the precipitated manganese sulfate crystals from the solution, use the filtrate for later use, and dry the manganese sulfate crystals in an oven (at a temperature of 80°C for 2 hours) to obtain high-purity manganese sulfate crystals.

[0038] Distill the filtrate of step to separate the organic solvent therefrom for recycling.

Embodiment 3

[0040] Add 200mL of manganese sulfate solution leached from manganese ore into the reaction vessel, then add 1M nitric acid to adjust the acidity to pH 3;

[0041] Then add 300mL of methanol, stir the mixed solution (temperature 40°C, speed 200 rpm, time 0.5 hours), after the precipitation of manganese sulfate crystals is complete, let stand at room temperature for 3 hours;

[0042] Filter and separate the precipitated manganese sulfate crystals from the solution, and use the filtrate for later use. Dry the manganese sulfate crystals in an oven (at a temperature of 60° C. for 8 hours) to obtain high-purity manganese sulfate crystals.

[0043] Distill the filtrate of step to separate the organic solvent therefrom for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com