Green and environment-friendly chromium-removing ceramic water reducing agent

A ceramic water reducer, a green and environmentally friendly technology, applied in the field of ceramic production additives, can solve the problems of hexavalent chromium pollution, no hexavalent chromium removal improvement, etc., and achieve the effects of reducing potential hazards, good synergy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

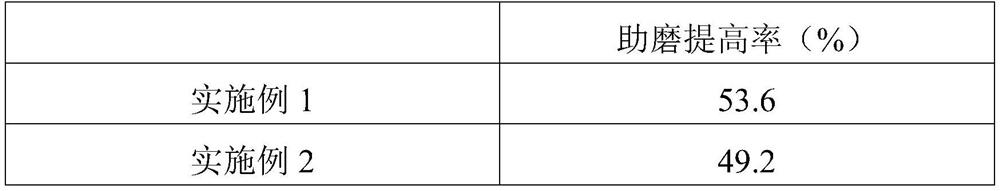

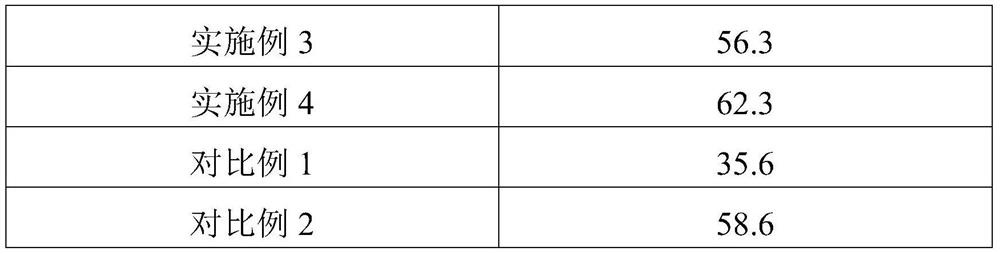

Embodiment 1

[0032] A green and environment-friendly chromium-removing ceramic water-reducer, the raw materials and proportions are: 500g of polycarboxylate mother liquor, 100g of triethanolamine, 100g of sodium carboxymethylcellulose, and 20g of graphene.

[0033]The preparation method of described polycarboxylic acid mother liquor is: at 50 ℃, with 15g poly(ethylene glycol) methyl ether methacrylate, 5g sodium allyl sulfonate, 0.4g ammonium persulfate, in rotating speed 350r Dissolve in 150g water at 1 / min to obtain mixed system I; then add 10g acrylic acid, 0.15g mercaptoacetic acid, and 1g tri(ethylene glycol) divinyl ether to mixed system I, stir at 50°C at 350r / min , After 4 hours of polymerization reaction, cool naturally at 25°C to obtain a mixed system II; adjust the pH of the mixed system II to 7.5 with 30% aqueous sodium hydroxide solution and water to obtain a polycarboxylate mother liquor.

Embodiment 2

[0035] A green and environment-friendly chromium-removing ceramic water-reducer, the raw materials and proportions are: 500g of polycarboxylate mother liquor, 100g of triethanolamine, 100g of sodium carboxymethylcellulose, and 20g of sodium alginate.

[0036] The preparation method of described polycarboxylic acid mother liquor is: at 50 ℃, with 15g poly(ethylene glycol) methyl ether methacrylate, 5g sodium allyl sulfonate, 0.4g ammonium persulfate, in rotating speed 350r Dissolve in 150g water at 1 / min to obtain mixed system I; then add 10g acrylic acid, 0.15g mercaptoacetic acid, and 1g tri(ethylene glycol) divinyl ether to mixed system I, stir at 50°C at 350r / min , After 4 hours of polymerization reaction, cool naturally at 25°C to obtain a mixed system II; adjust the pH of the mixed system II to 7.5 with 30% aqueous sodium hydroxide solution and water to obtain a polycarboxylate mother liquor.

Embodiment 3

[0038] A green and environment-friendly chromium-removing ceramic water-reducer, its raw materials and proportions are: 500g of polycarboxylate mother liquor, 100g of triethanolamine, 100g of sodium carboxymethylcellulose, 4g of graphene, and 16g of sodium alginate.

[0039] The preparation method of described polycarboxylic acid mother liquor is: at 50 ℃, with 15g poly(ethylene glycol) methyl ether methacrylate, 5g sodium allyl sulfonate, 0.4g ammonium persulfate, in rotating speed 350r Dissolve in 150g water at 1 / min to obtain mixed system I; then add 10g acrylic acid, 0.15g mercaptoacetic acid, and 1g tri(ethylene glycol) divinyl ether to mixed system I, stir at 50°C at 350r / min , After 4 hours of polymerization reaction, cool naturally at 25°C to obtain a mixed system II; adjust the pH of the mixed system II to 7.5 with 30% aqueous sodium hydroxide solution and water to obtain a polycarboxylate mother liquor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com