A triaxial sample preparation device for silty soil with low liquid limit

A silty soil, low liquid limit technology, applied in the field of geomechanics triaxial test sample preparation, can solve problems such as high requirements for sample preparation equipment, secondary disturbance of samples, influence of test results, etc., to improve dimensional accuracy The effect of sealing effect, saturation and pressure consolidation speed, and the effect of improving vibration encryption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

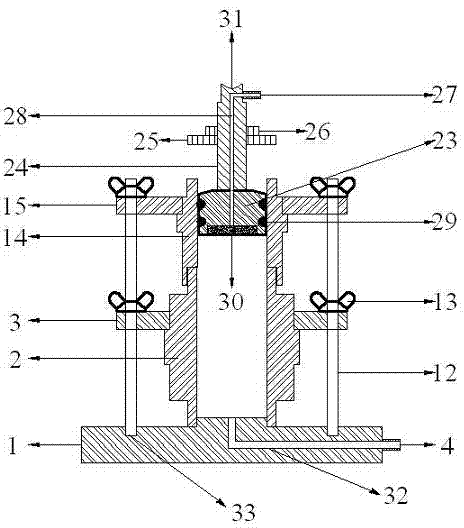

[0023] A triaxial sample preparation device for low liquid limit silty soil of the present invention, comprising: a sample cylinder, a leveler, a vibrator and a loader;

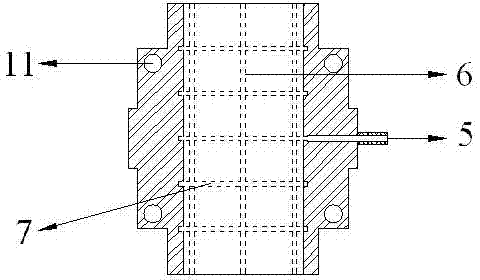

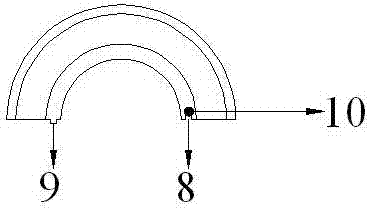

[0024] The sample cylinder further includes: a base 1, a split mold 2, a split mold fixing plate 3, an expansion cylinder 14, and a volume expansion cylinder fixing plate 15; the two ends of the base 1 are provided with threaded circular grooves 33, and the center is provided with a circular groove. Shaped boss, the center vertical line between the circular boss and the side of the base is provided with a first air guide and water guide channel, and the outlet of the first air guide and water guide channel is provided with a first air guide and water guide hole 4; split mold 2 The lower end is matched with the circular boss, the upper end of the split mold 2 is matched with the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com