Preparation method of density-controllable B10-rich boron carbide ceramic

A technology of boron carbide ceramics and boron carbide, applied in the field of preparation of density-controllable B10-rich boron carbide ceramics, can solve the problems of increased manufacturing costs, processing difficulties, waste of raw materials, etc., to reduce processing and production costs, facilitate industrial production, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

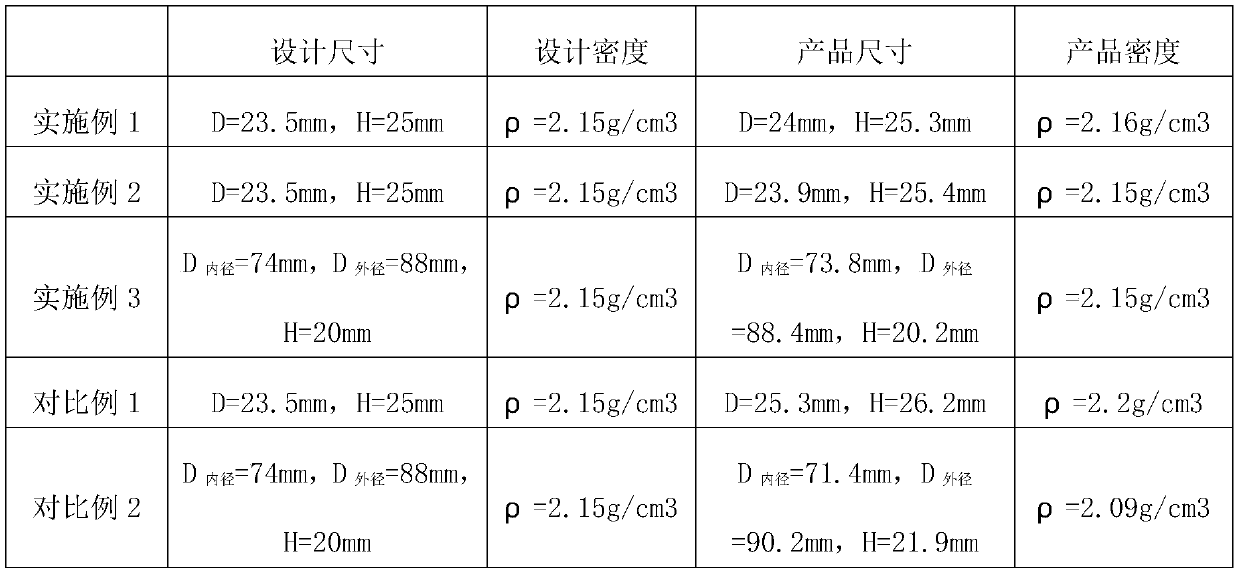

Embodiment 1

[0019] Design a kind of D=23.5mm, the columnar abundance of H=25mm is 92 rich B10 boron carbide ceramics, the design density is Including the following steps:

[0020] 1) Dry B10-rich boron carbide ceramic powder with an abundance of 92 and a particle size of 3-5 μm in a vacuum oven at 80°C-110°C for 8-24h;

[0021] 2) Weigh the dried B10-rich boron carbide ceramic powder and put the B10-rich boron carbide ceramic powder into a special high-strength, high-density graphite mold. The design is divided into two parts, the end cover is designed to have grooves, and a layer of graphite paper with a thickness of 0.1-0.5mm is pasted on the contact part between the graphite mold and the B10-rich boron carbide powder;

[0022] 3) Put the graphite mold filled with B10-rich boron carbide ceramic powder in step 2) into a hydraulic press for holding pressure for 3-10 minutes, with a holding pressure of 3-5 tons;

[0023] 4) Put the graphite mold maintained under pressure in step 3) in...

Embodiment 2

[0026] Design a D=23.5mm, H=25mm columnar abundance of 80 rich B10 boron carbide ceramics, the design density is Including the following steps:

[0027] 1) Dry B10-rich boron carbide ceramic powder with abundance 80 and particle size 0.5-2 μm in a vacuum oven at 80°C-110°C for 8-24h;

[0028] 2) Weigh the dried B10-rich boron carbide ceramic powder and put the B10-rich boron carbide ceramic powder into a special high-strength, high-density graphite mold. The design is divided into two parts, the end cover is designed to have grooves, and a layer of graphite paper with a thickness of 0.1-0.5mm is pasted on the contact part between the graphite mold and the B10-rich boron carbide powder;

[0029] 3) Put the graphite mold filled with B10-rich boron carbide ceramic powder in step 2) into a hydraulic press for holding pressure for 3-10 minutes, with a holding pressure of 3-5 tons;

[0030] 4) Put the graphite mold maintained under pressure in step 3) into a hot-press furnace f...

Embodiment 3

[0033] Design a kind of D inner diameter=74mm, D outer diameter=88mm, H=20mm annular abundance is the rich B10 boron carbide ceramics of 85, the design density is Including the following steps:

[0034] 1) Dry B10-rich boron carbide ceramic powder with abundance 85 and particle size 0.7-2 μm in a vacuum oven at 80°C-110°C for 8-24h;

[0035] 2) Weigh the dried B10-rich boron carbide ceramic powder and put the B10-rich boron carbide ceramic powder into a special high-strength, high-density graphite mold. The design is divided into two parts, the end cover is designed to have grooves, and a layer of graphite paper with a thickness of 0.1-0.5mm is pasted on the contact part between the graphite mold and the B10-rich boron carbide powder;

[0036] 3) Put the graphite mold filled with B10-rich boron carbide ceramic powder in step 2) into a hydraulic press for holding pressure for 3-10 minutes, with a holding pressure of 3-5 tons;

[0037] 4) Put the graphite mold maintained unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com