A kind of lightweight high specific strength modified polypropylene material and its preparation method

A polypropylene material, high specific strength technology, applied in the field of polymer materials, can solve the problems of difficult implementation, low cost performance, high density of modified polypropylene materials, etc., to prevent glass fiber leakage, high cost performance, and ensure structural integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

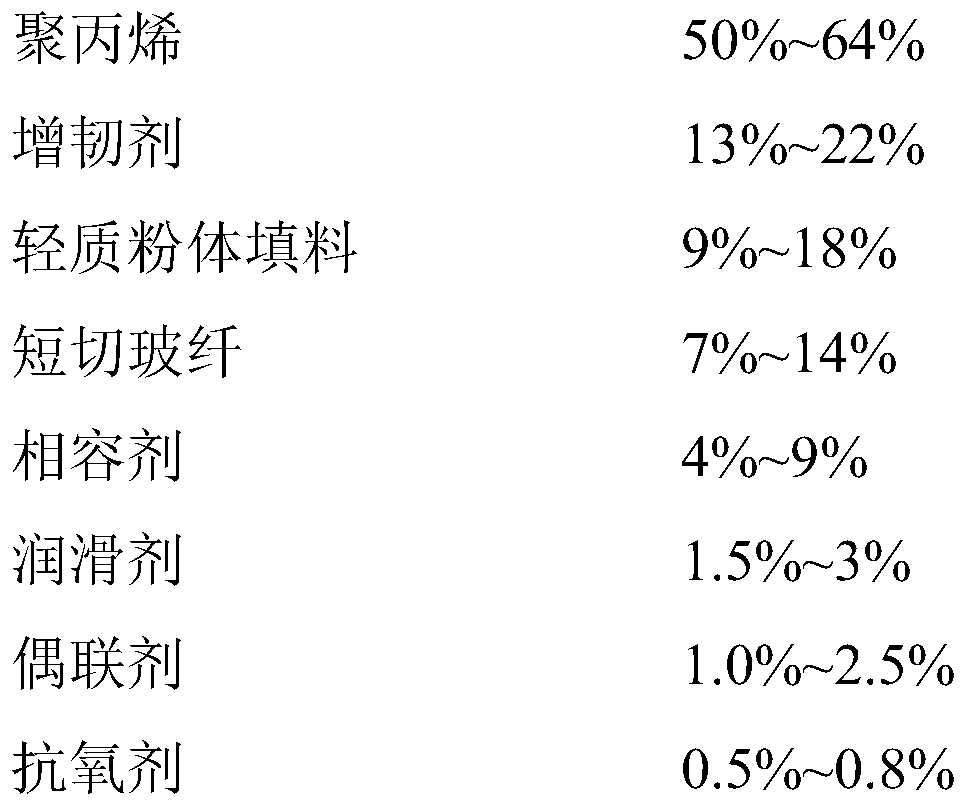

[0033] A light weight high specific strength modified polypropylene material, its formula is as follows:

[0034]

[0035] Its preparation method comprises the following steps:

[0036] a. Mix the amount of M2600R, EPDM3745P, maleic anhydride grafted polypropylene, polyethylene wax and antioxidant 1010 in a high-speed mixer. The speed of the high-speed mixer is controlled at 500rpm-1500rpm, and the final material temperature is controlled at 70°C ~80°C, the materials are mixed evenly and unloaded for later use;

[0037] b. Add the formulated amount of GS60 and KH-550 into the high-speed mixer for activation and modification. The speed of the high-speed mixer is controlled at 500rpm-1000rpm, and the final material temperature is controlled at 85°C-95°C;

[0038] c. Mix the material prepared in step b with T438 evenly at room temperature in a high-speed mixer, and the speed of the high-speed mixer is controlled at 300rpm-500rpm;

[0039] d. The material prepared by step a a...

Embodiment 2

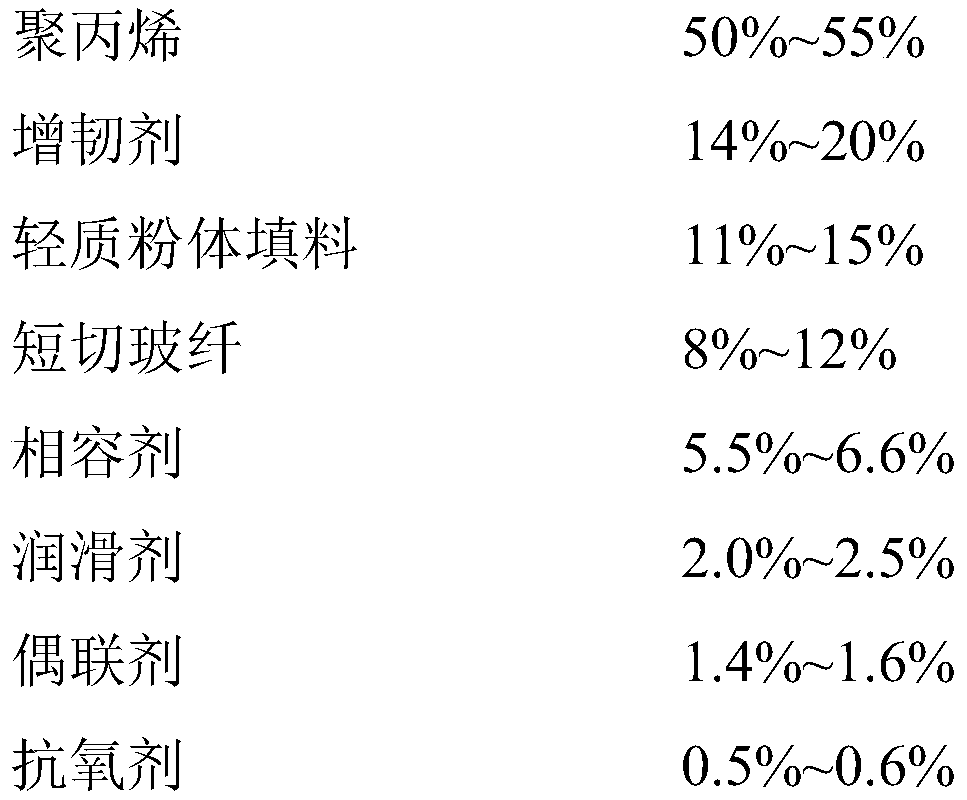

[0041] A light weight high specific strength modified polypropylene material, its formula is as follows:

[0042]

[0043] Its preparation method comprises the following steps:

[0044] a. Mix Y3000, POE5371, maleic anhydride grafted polypropylene, polyethylene wax and antioxidant 1010 in a high-speed mixer. The speed of the high-speed mixer is controlled at 500rpm-1500rpm, and the final material temperature is controlled at 70°C ~80°C, the materials are mixed evenly and unloaded for later use;

[0045] b. Add the formulated amount of GS60 and KH-550 into the high-speed mixer for activation and modification. The speed of the high-speed mixer is controlled at 500rpm-1000rpm, and the final material temperature is controlled at 85°C-95°C;

[0046] c. Mix the material prepared in step b with S508A evenly at room temperature in a high-speed mixer, and the speed of the high-speed mixer is controlled at 300rpm-500rpm;

[0047]d. The material prepared by step a and step b and S50...

Embodiment 3

[0049] A light weight high specific strength modified polypropylene material, its formula is as follows:

[0050]

[0051] Its preparation method comprises the following steps:

[0052] a. Mix K9920, K2420, POE5371, maleic anhydride-grafted polypropylene, polyethylene wax and antioxidant 1010 in a high-speed mixer. The speed of the high-speed mixer is controlled at 500rpm-1500rpm, and the final material temperature is controlled at 70 ℃ ~ 80 ℃, the material is mixed evenly and unloaded for later use;

[0053] b. Add the formulated amount of GS60 and KH-550 into the high-speed mixer for activation and modification. The speed of the high-speed mixer is controlled at 500rpm-1000rpm, and the final material temperature is controlled at 85°C-95°C;

[0054] c. Mix the material prepared in step b with S508A evenly at room temperature in a high-speed mixer, and the speed of the high-speed mixer is controlled at 300rpm-500rpm;

[0055] d. The material prepared by step a and step b ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com