Precise intelligent winding machine and winding control method thereof

A winding machine, intelligent technology, applied in the field of dyeing machinery, can solve problems such as uneven shrinkage, color flower, etc., and achieve the effect of simple and easy control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

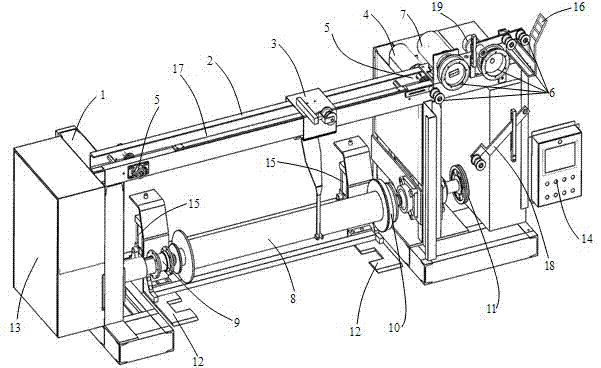

[0034] Such as Figure 1 to Figure 2 As shown, a precision intelligent winding machine includes a bracket 1, a guide rail 2 horizontally arranged on the bracket 1, a pressing arm assembly 3 that translates back and forth along the guide rail 2, and a roller group 6 that is sequentially arranged at one end of the guide rail 2 to drive the fabric. And feed support 16, send tape servomotor 7, reel 8 and pneumatic equipment, be arranged on belt pulley 11 and reel drive motor at one end of reel 8, described send tape servomotor 7 is connected with the driving roller in the roller group 6,

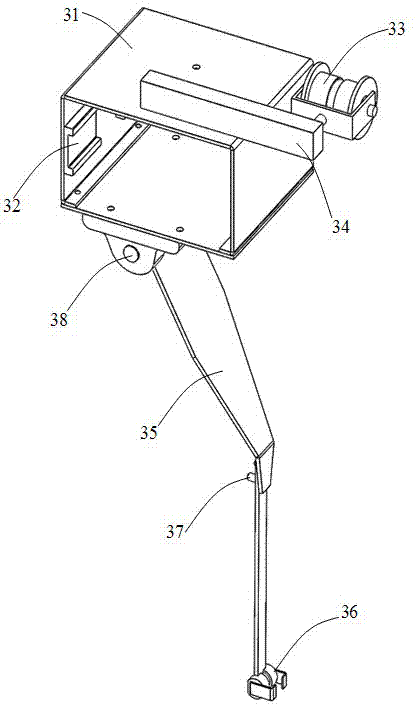

[0035] It also includes a tension resistance device 19 arranged on the roller set 6 and a central controller 14 arranged on one side of the frame 1, a first tension sensor 34 is arranged on the pressing arm assembly 3, and a tension sensor 34 is arranged under the roller set 6 The second tension sensor 18 with gravity wheel fixed on the support 1 is used to sense the tension of the fabric, and t...

Embodiment 2

[0043] A coil material control method for a precision intelligent winding machine, comprising the steps of:

[0044] A. Start the winding machine, the lifting bracket 12 lifts the reel 8 to a predetermined position under the action of the lifting cylinder 15, and the pneumatic box 13 controls the locking cylinder 9 to connect the reel 8 with the locking pan head 10;

[0045] B. Start the tape feeding servo motor 7 and the reel drive motor, and obtain the tension value of the rolled fabric through the tension sensor;

[0046] C. When the tension value monitored by the central controller 14 is less than the lower limit of the preset tension value range, the speed of the tape feeding servo motor 7 is reduced, or the speed of the reel drive motor is accelerated, or the tension resistance device 19 is controlled to increase the tension;

[0047] When the tension value monitored by the central controller 14 is greater than the upper limit of the preset tension value range, the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com