Sample production method for disturbed soil for conventional triaxial test, and method thereof

A triaxial test, a conventional technology, applied in the measurement device, preparation of test samples, sampling, etc., can solve the problems of flexible adjustment of soil sample height-diameter ratio, inaccurate control of compactness, uneven soil sample preparation, etc. Real and reliable test results, precise control of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

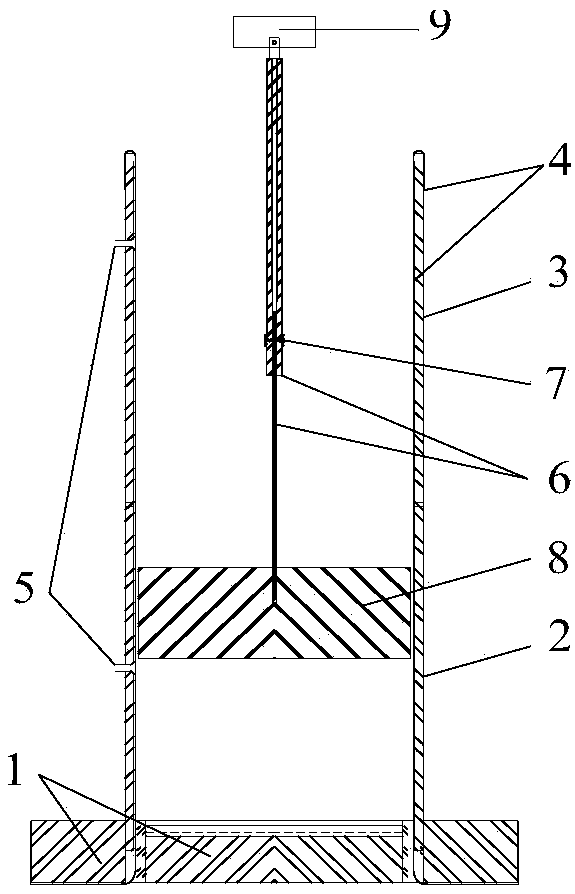

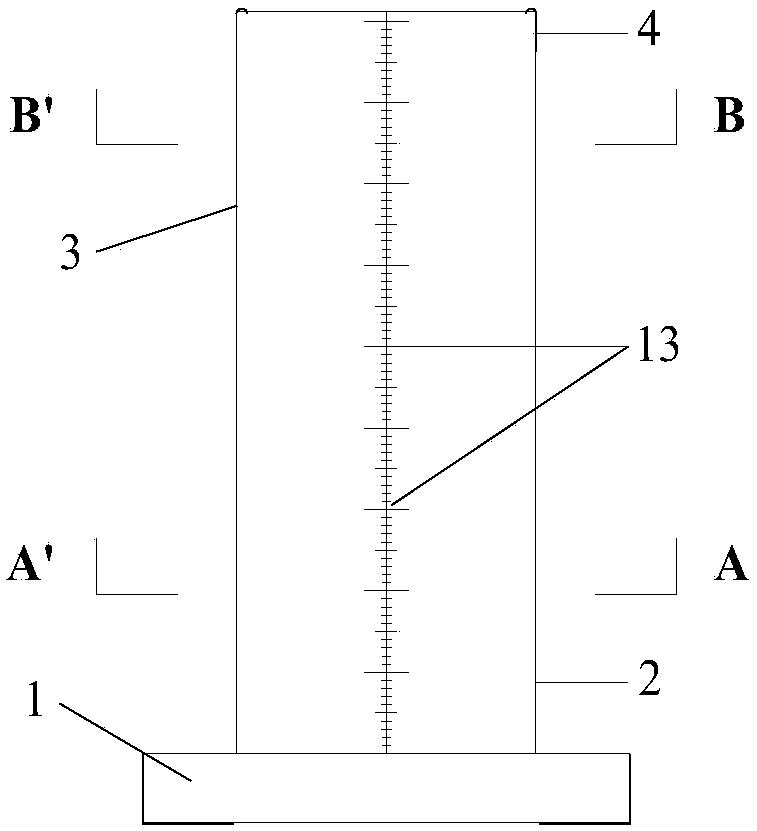

[0056] Such as Figure 1-Figure 10 As shown, the conventional triaxial test disturbs the soil sample device, including the sample preparation cylinder and the compaction equipment set in the sample preparation cylinder.

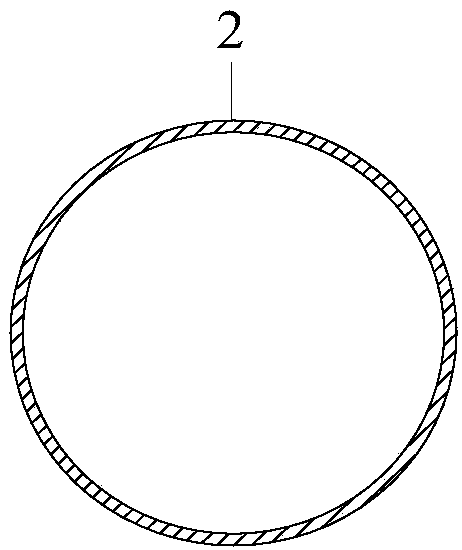

[0057] The sample preparation cylinder includes a base 1, a lower casing 2, an upper casing 3, and a rubber mold 4. The lower casing 2 is placed on the base 1, and the upper part of the lower casing 2 is connected with the upper casing 3 to form the casing main body. Casing 3 can be stretched up and down along the lower casing 2 to adjust the total height of the casing main body. The front and back outer walls of the casing main body are provided with uniform scale lines 13 with a unit length of 1 mm. The zero scale line is located at the lower casing 3 At the lower end, the material of the sample preparation cylinder is transparent tempered glass. After the rubber mold 4 passes through the casing, it is close to the inner wall of the cylinder and the two end...

Embodiment 2

[0060] Taking disturbed cohesive soil as an example, the operation process of the triaxial test disturbed soil sample method using the conventional triaxial test disturbed soil sample device described in Example 1 is described:

[0061] Step 1: Equipment Installation

[0062] ① First, calculate the sample preparation height according to the sample height-to-diameter ratio and the soil sample diameter. If the height of the soil sample is less than or equal to the height of the lower casing 2, the lower casing 2 can be directly used to prepare the soil sample; otherwise, it should be combined with the upper casing 3. Make soil samples. Here is a more complicated situation, that is, the sample preparation process of the joint use of the upper casing 3 and the lower casing 2 is explained;

[0063] ②Connect the upper end of the lower casing 2 with the lower end of the upper casing 3 through internal and external threads, adjust the total height of the casing according to the sampl...

Embodiment 3

[0082] The structure and connection relationship of each part of the conventional triaxial test disturbed soil sample device described in this embodiment are the same as those in Embodiment 1, and the different technical parameters are:

[0083] 1) The diameter of the exhaust hole 5 is 1.7mm;

[0084] 2) The height of the base 10 is 3cm;

[0085] 3) The diameter of the hole is slightly larger than the outer diameter of the lower casing 2, and the difference between the two is 0.25mm;

[0086] 4) The cross-sectional diameter of the backing plate 11 is the same as that of the permeable stone 12 and slightly smaller than the diameter of the hole in the base 10, with a difference of 0.4 mm;

[0087] 5) The aspect ratio of the lower casing 2 is 2.2;

[0088] 6) The wall thickness of the lower casing 2 is 1.2mm;

[0089] 7) The wall thickness of the upper casing 3 is 0.7mm;

[0090] 8) The lower end of the upper hollow rod 15 of the dowel 6 is slightly above the position to open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com