Environmentally friendly fully enclosed bulk bulk sample preparation system

A sample preparation system, a fully enclosed technology, applied to the sampling and sample preparation system with the function of discarding samples. It has the fields of feeding, shrinking, sample collection, and crushing, and can solve the high level of operating costs of the sample preparation system and increase the labor of the staff. Strength, increase the difficulty of other equipment layout, etc., to achieve the effect of light weight, small footprint, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

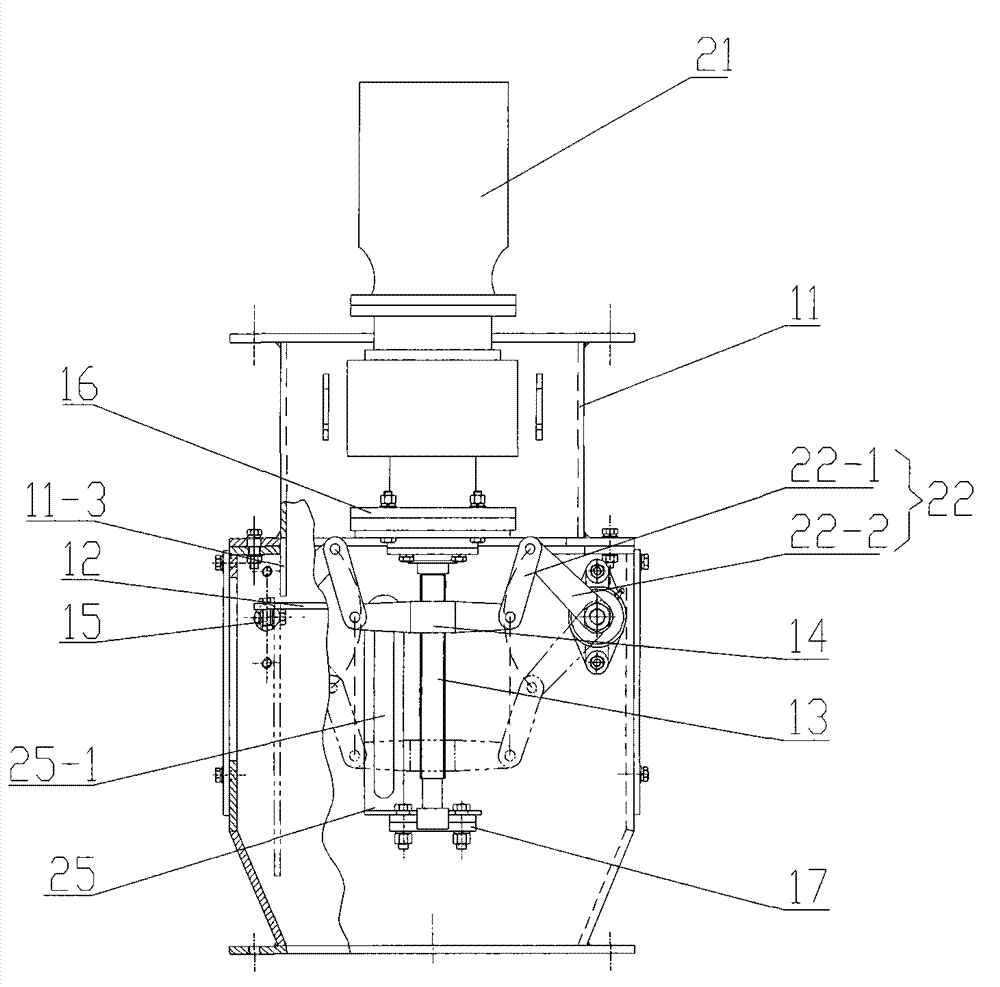

[0052] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

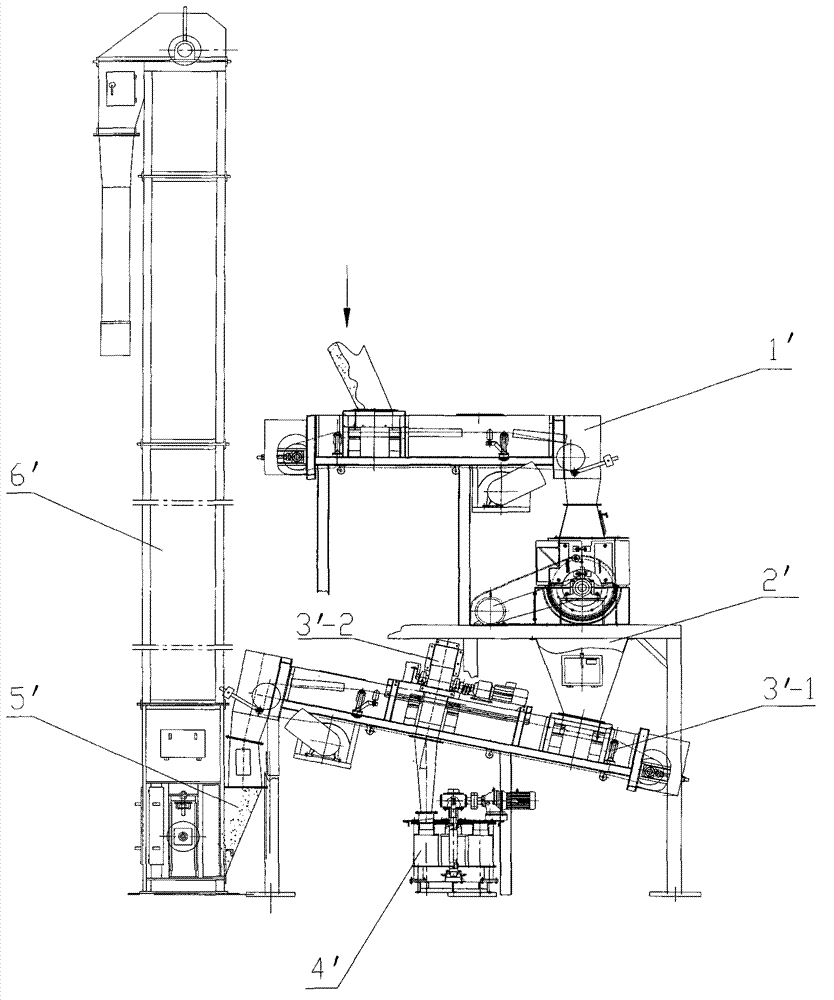

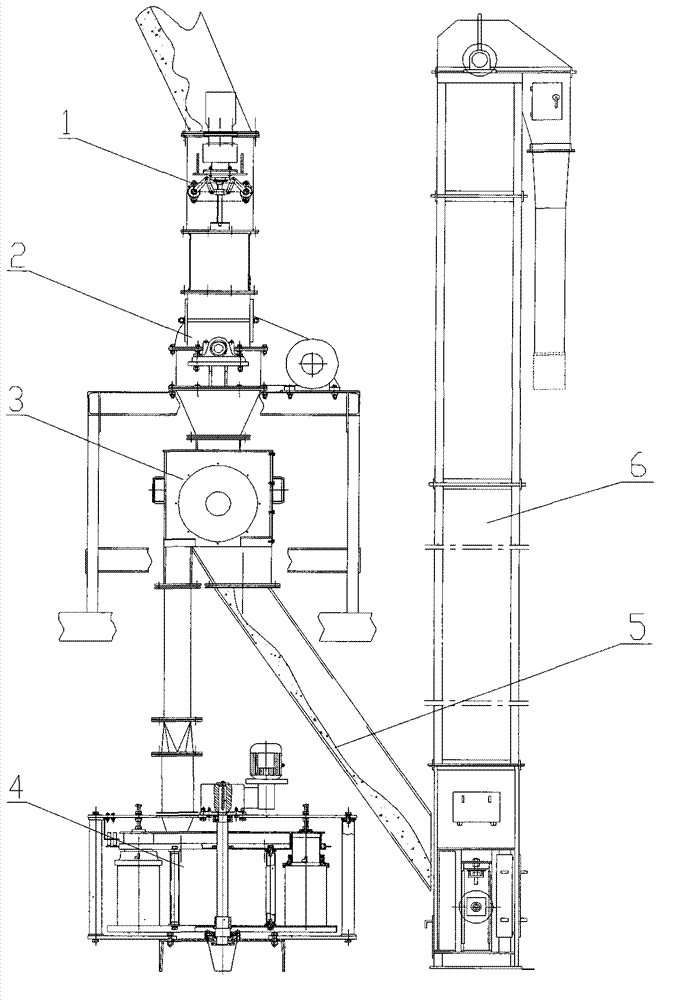

[0053] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a specific embodiment of an environment-friendly fully enclosed bulk material sample preparation system provided by the present invention.

[0054]In a specific embodiment, the sample preparation system provided by the present invention is mainly composed of feeder 1, crusher 2, shrinker 3, sample collector 4 and other equipment, wherein feeder 1, crusher 2, The splitter 3 and the sample collector 4 are vertically arranged from top to bottom, and the discharge port and the feed port are sequentially connected to each other through the flange interface, forming a fully enclosed structure as a whole, and the discharge port of the splitter 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com