Patents

Literature

40results about How to "To achieve the purpose of increasing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compounded weed killer of glyphosate and glufosinate

InactiveCN101773143AImprove the effect of prevention and controlGood effectBiocideAnimal repellantsOrchardWeed

The invention relates to a pesticide composition, in particular to a compounded weed killer of glyphosate and glufosinate, which can be used for preventing and controlling weeds in farmlands, orchards, tea gardens, vegetable fields, uncultivated areas and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Method for extracting and recovering silver from waste solar cell

InactiveCN102851506ATake advantage ofReduce manufacturing costProcess efficiency improvementElectronic waste recyclingIron powderSilver electrode

The invention provides a method for extracting and recovering silver from a waste solar cell, and relates to a technology of solar material washing. The method comprises the following steps: a, washing the surface of a waste solar cell; b, soaking in hydrochloric acid to remove an aluminum back surface field; c, rinsing a silicon wafer subjected to aluminum back surface field removal with pure water, and then soaking in nitrohydrochloric acid to remove a silver electrode on the silicon wafer; d, adding HF into the nitrohydrochloric acid to remove a silicon nitride blue membrane on the surface, thus obtaining a clean silver extraction wafer; e, rinsing the silver extraction wafer with pure water, soaking in mixed acid, and cleaning to obtain clean fragments; and f, adding high-purity iron powder into the nitrohydrochloric acid solution, stirring, filtering silver powder after the reaction is finished, drying, proportioning, and smelting to obtain a high-quality silver ingot. The invention has the following beneficial effects: through the properties of different kinds of acid, the aluminum, silver and silicon nitride on the cell can be subjected to independent treatment, so that the cell can be fully utilized; meanwhile, the silver can be recovered, and about 0.6kg of silver can be recovered from 50kg of cell; and the silicon ingot production cost can be effectively reduced, thereby achieving the synergy purpose.

Owner:ANYANG PHOENIX PHOTOVOLTAIC TECH

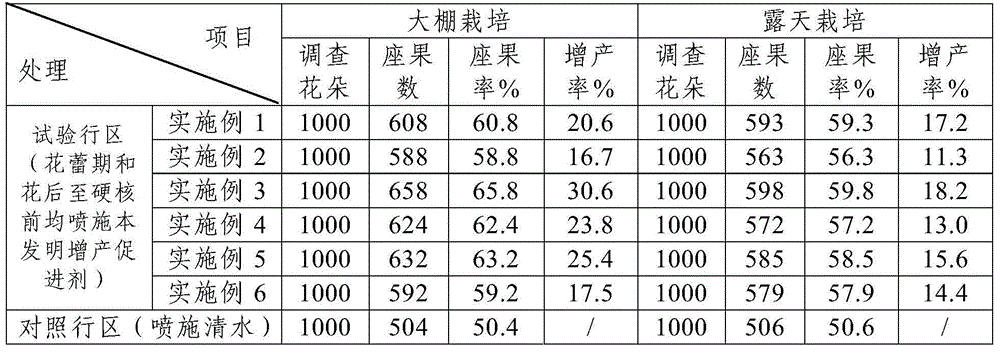

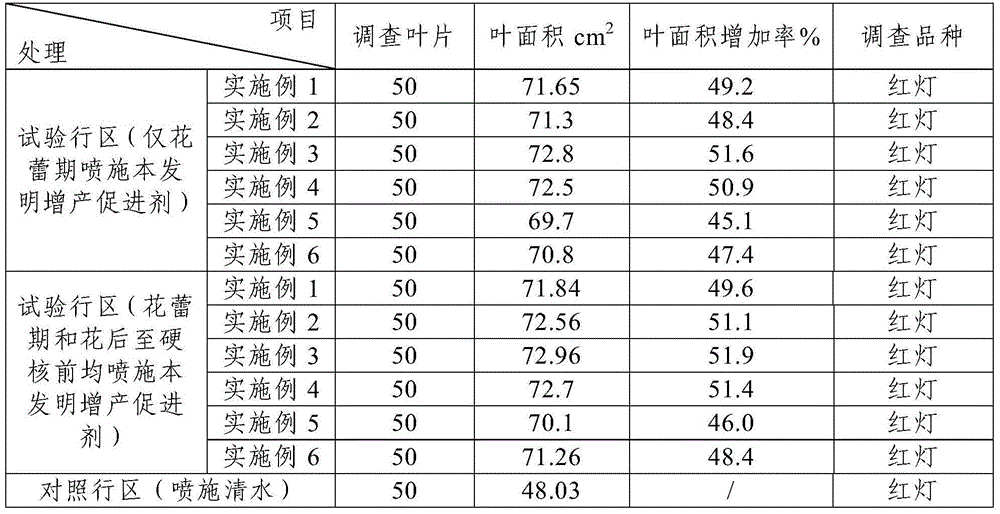

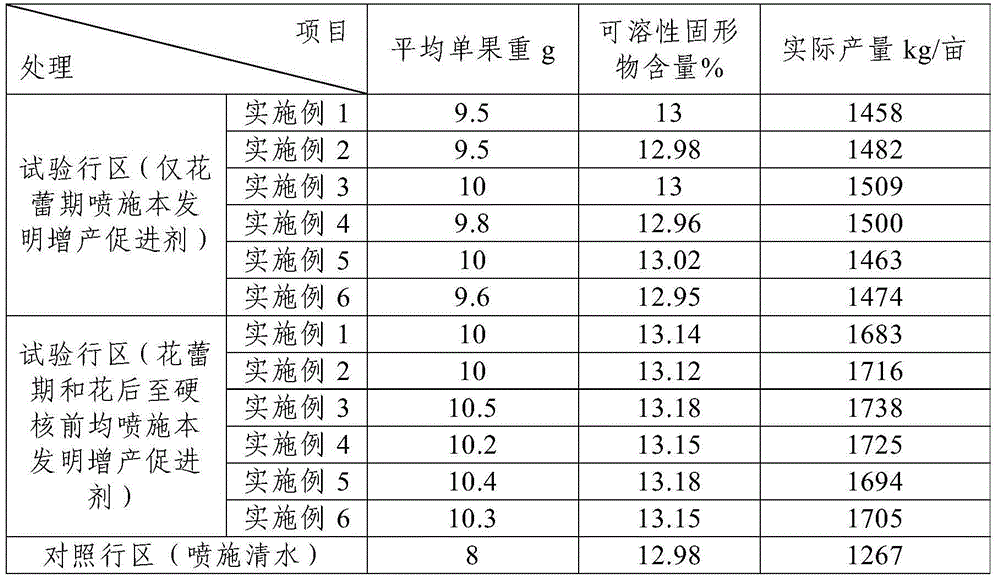

Yield-increase accelerant for preventing flower and fruit dropping of large cherry and preparation method thereof

InactiveCN104823991APromote formationPromote floweringBiocidePlant growth regulatorsCell divisionFruit set

The invention discloses a yield-increase accelerant for preventing flower and fruit dropping of large cherry. The yield-increase accelerant is prepared from the following raw materials by the mass percentage: 0.2%-0.4% of phethalanilic acid, 0.1%-0.35% of 6-benzylaminopurine, 0.08%-0.2% of auxin, 2.8%-4.0% of brassinosteroid, 0.5%-2.5% of a penetrating agent, and the balance dimethylformamide. In addition, the invention also discloses a preparation method of the yield-increase accelerant. The yield-increase accelerant can promote pollination and fertilization of the large cherry, has flower and fruit retention effects, effectively prevents flower and fruit dropping of the large cherry, improves the fruit-setting ratio of the large cherry, induces cell division of large cherry fruits, improves the quality of the large cherry, increases the single fruit weight to the greatest extent, thereby improving the yield and achieving purposes of increasing yield, income and efficiency.

Owner:郭徐澄

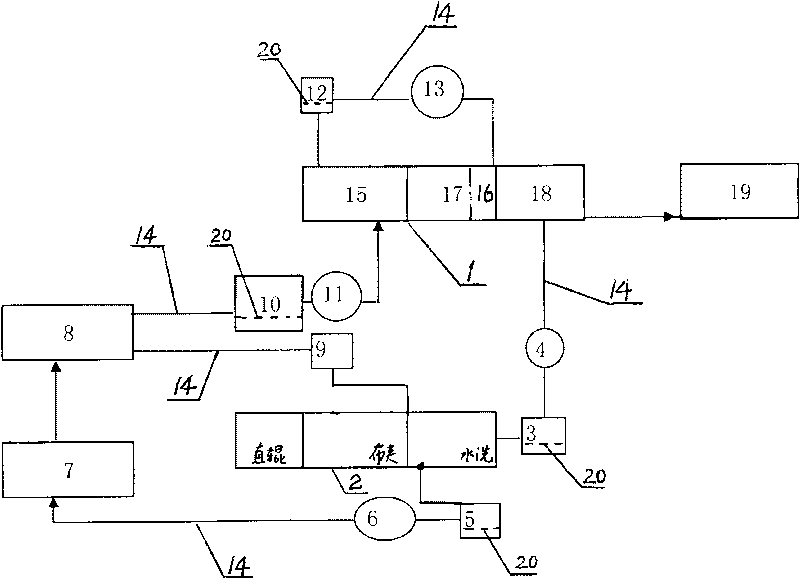

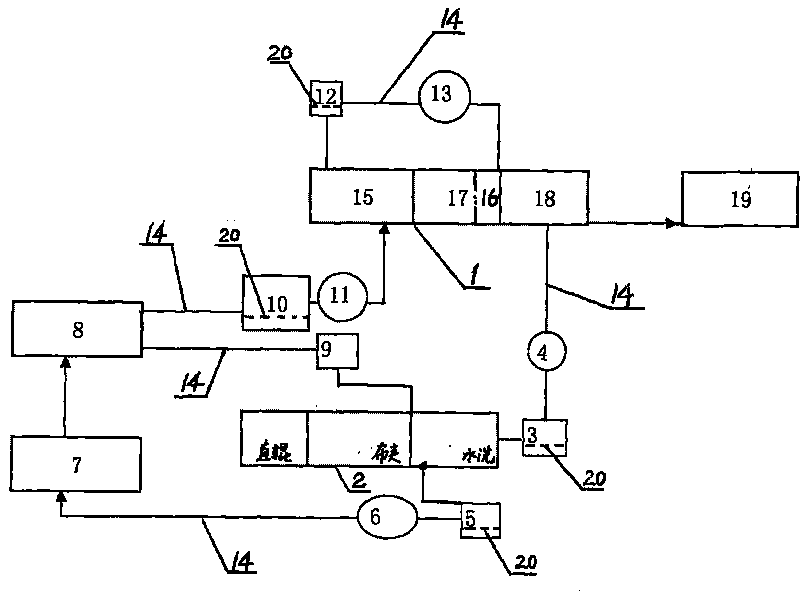

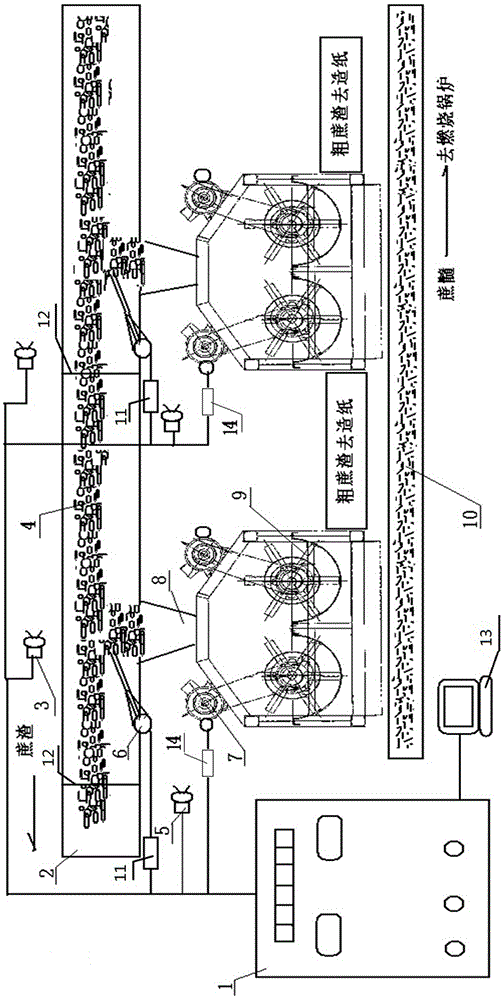

Waste water recycling pad dyeing long machine and waste water recycling method thereof

InactiveCN101748576AEmission reductionReduce dosageTextile treatment machine arrangementsHigh concentrationWater discharge

The invention discloses a waste water recycling pad dyeing long machine and a waste water recycling method thereof. The waste water recycling pad dyeing long machine comprises a desizing, scouring and bleaching combined machine, a mercerizer, a first recovery processing box, a second recovery processing box, a third recovery processing box, a first recovery pump, a second recovery pump, a third recovery pump, a light alkali recovery pool, a dilatation evaporator, an alkali dosing pool, a recovery pool, a recovery pump and connecting pipelines. The method comprises the following steps: a. introducing washing waste water into the first recovery processing box and then pumping into a scouring machine after filtering; b. introducing light alkali with high alkali concentration into the dilatation evaporator for processing through the recovery pool, then introducing processed high-concentration alkali liquor into the mercerizer for reuse and introducing processed water into an oxygen bleaching washing box for use; and c. introducing oxygen bleaching process water into the second recovery processing box and then introducing into a desizing machine washing box for use after filtering. The invention has the advantages of small waste water discharge, high efficiency, energy conservation, etc., saves a large amount of production water and alkali, and meets requirements of energy saving and emission reduction.

Owner:李传海

Slow-acting multifunctional compound microorganism fertilizer and process for producing same

InactiveCN108424272AReduce volatilityExtended shelf lifeBio-organic fraction processingExcrement fertilisersPotassiumPalygorskite

The invention discloses a slow-acting multifunctional compound microorganism fertilizer and a process for producing the same. The slow-acting multifunctional compound microorganism fertilizer comprises, by weight, 15-25 parts of nitrogen, phosphorus and potassium compound fertilizers, 5-10 parts of peony seed cake, 10-20 parts of peony shells / leaves, 10-20 parts of feculae bombycis, 5-10 parts ofmineral palygorskite, 5-10 parts of potassium fulvic acid, 2-5 parts of disease and insect resistant components extracted from traditional Chinese medicinal materials, 1-3 parts of trace elements and5-8 parts of EM (effective microorganism) bacteria. The contents of N+P2O5+K2O in the slow-acting multifunctional compound microorganism fertilizer are higher than or equal to 15-25%, the effective viable bacterial count of the slow-acting multifunctional compound microorganism fertilizer is higher than or equal to 300 hundred million / kg, the moisture content of the slow-acting multifunctional compound microorganism fertilizer is lower than or equal to 30%, and the organic matter content of the slow-acting multifunctional compound microorganism fertilizer is higher than or equal to 20%. The slow-acting multifunctional compound microorganism fertilizer and the process have the advantages that the slow-acting multifunctional compound microorganism fertilizer is in a scientific formula, contains complete nutrients, is lasting in fertilizer efficiency, high in fertilizer utilization rate and free of pollution or public hazards and is antibacterial, green and ecological, multiple effects can be realized by the single slow-acting multifunctional compound microorganism fertilizer, insects can be prevented by the slow-acting multifunctional compound microorganism fertilizer, obvious effects of improving soil environments can be realized by the slow-acting multifunctional compound microorganism fertilizer, the yield of crops can be increased by the slow-acting multifunctional compound microorganism fertilizer, and the quality of the crops can be improved by the slow-acting multifunctional compound microorganism fertilizer.

Owner:四川国康农业科技有限公司

Early-maturing high-yield high-density cultivation method for winter peaches

InactiveCN107409903APrevent compactionFully absorbedBiocideCalcareous fertilisersDiseaseLand resources

The invention discloses an early-maturing high-yield high-density cultivation method for winter peaches. The method includes the steps of field preparation and selection, planting of peach seedlings, daily management and harvesting, wherein during planting of the peach seedlings, deep tillage is conducted on soil, basic fertilizer is applied, and high-quality strong seedlings of the winter peaches are selected for planting; the daily management includes the aspects of management of soil, water and fertilizer, prevention and control of diseases and pests and trimming for shaping; during harvesting, fruits are picked after ripening. According to the early-maturing high-yield high-density cultivation method for the winter peaches, planting density is high, land resources are fully utilized, and meanwhile, the soil fertility is improved, the winter peaches grow fast, the growth period is short, diseases and pests are unlikely to occur, the winter peaches are high in yield and excellent in quality, and the economic benefit of winter peach planting is effectively increased.

Owner:来安县世外桃园生态农业专业合作社

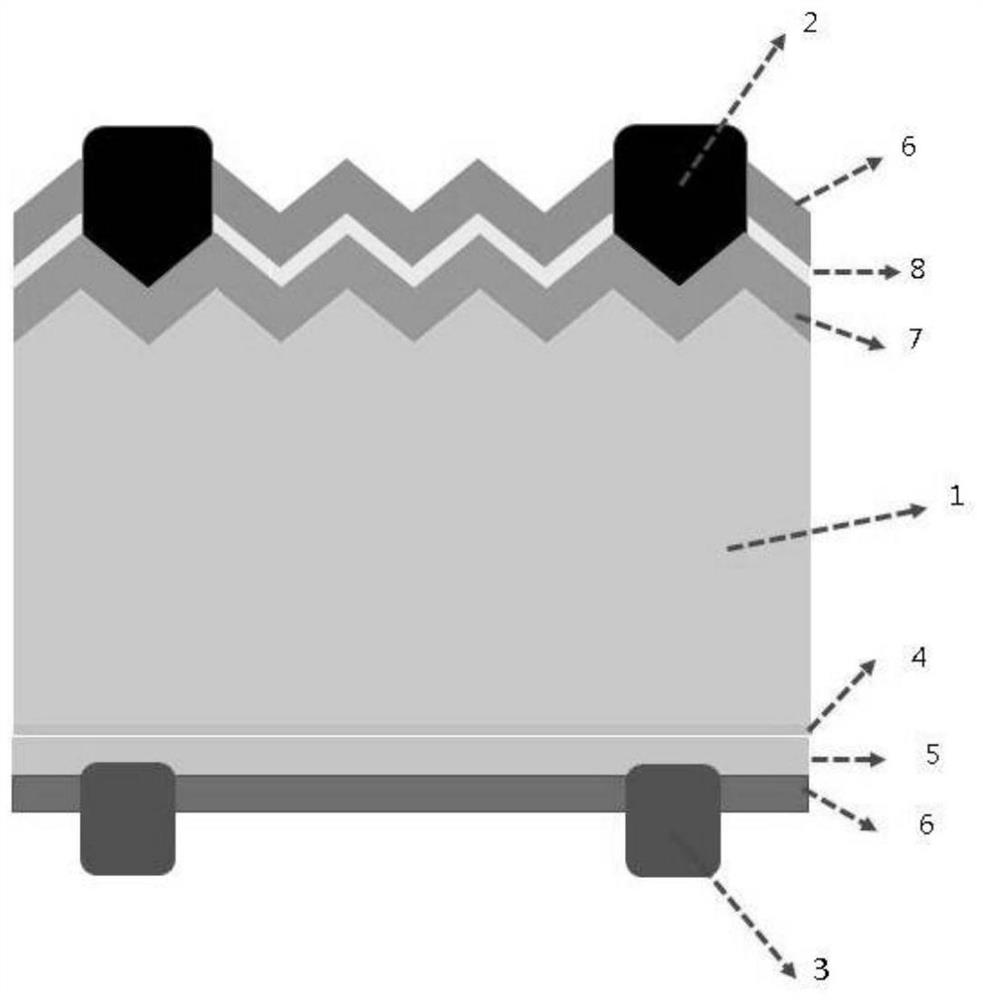

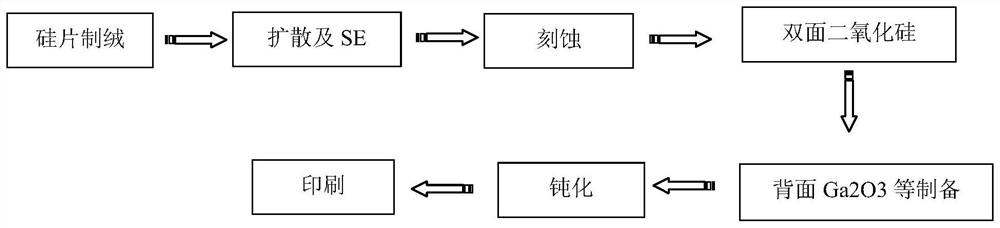

Passivation structure applied to contact passivation battery and preparation method of passivation structure

PendingCN112670352AReduce light absorptionReduce contact resistanceFinal product manufacturePhotovoltaic energy generationPhysicsElectrical battery

The invention relates to the technical field of solar batteries, and discloses a passivation structure applied to a contact passivation battery and a preparation method of the passivation structure in order to solve the problem of high light absorption rate of a contact passivation layer in a TOPCon battery in the prior art. The passivation structure comprises an N-type substrate, two positive electrodes arranged on the front surface of the N-type substrate, and two negative electrodes arranged on the back surface of the N-type substrate, wherein a SiO2 layer is arranged on the back surface of the N-type substrate, and a doped polycrystalline SiOxNy layer is arranged on the SiO2 layer. According to the invention, the doped polycrystalline silicon oxynitride layer is used for replacing a polycrystalline silicon layer, and on the basis of ensuring small change of contact resistance, the light absorption of the contact passivation layer is reduced through doping and annealing under proper conditions, and the efficiency of the contact passivation type cell is improved.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

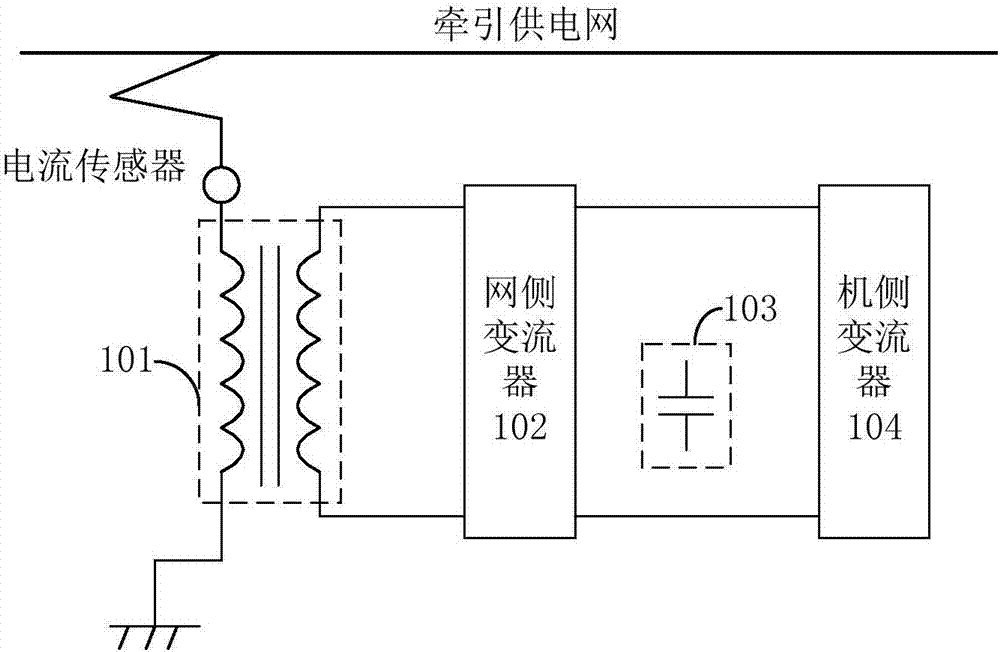

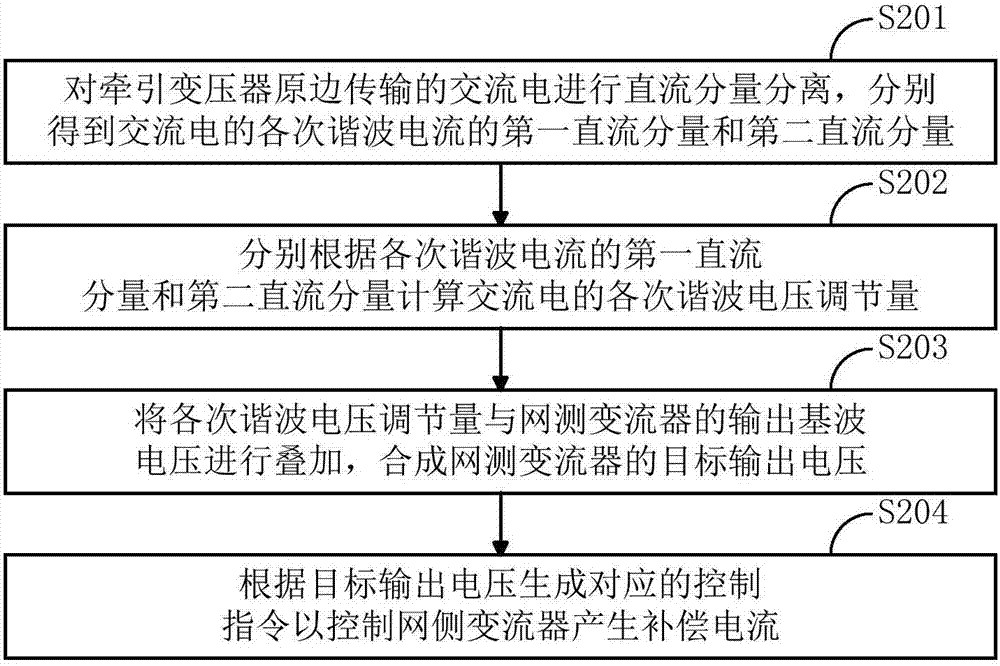

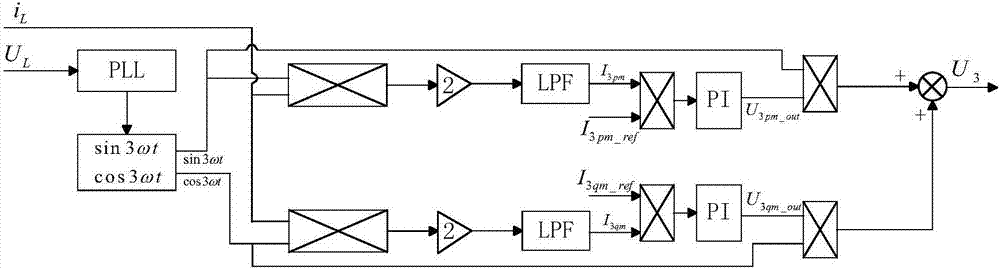

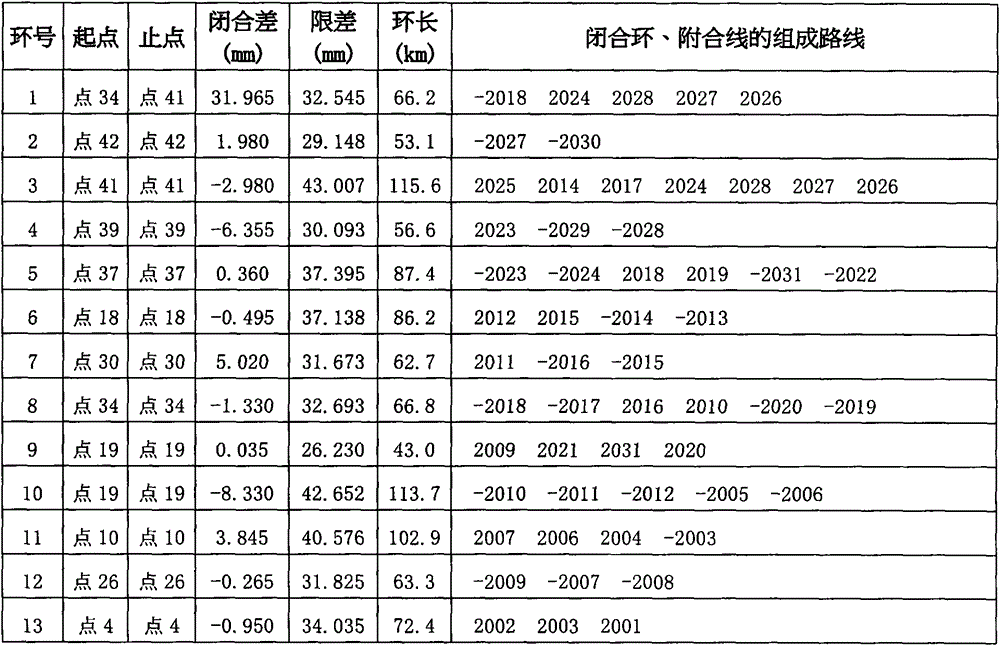

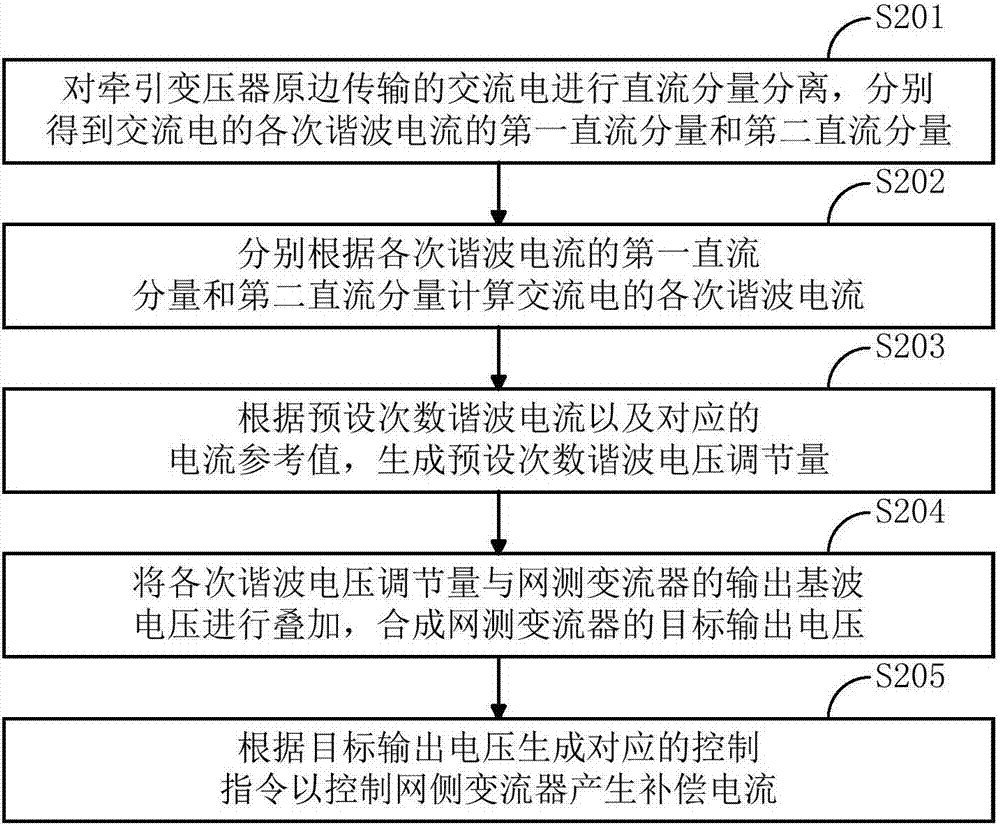

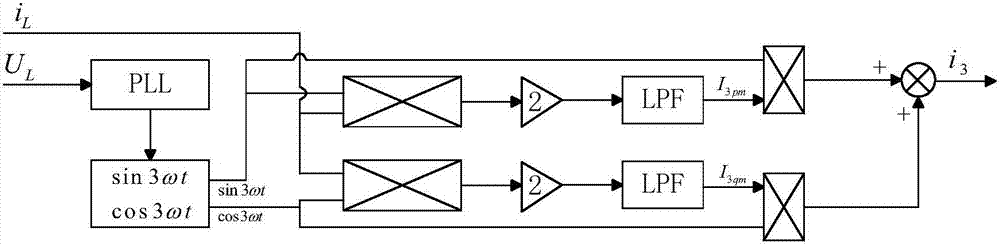

Electric locomotive harmonic suppression method

InactiveCN107546739AAchieve flexibilityImprove safety and reliabilityHarmonic reduction arrangementAc network to reduce harmonics/ripplesDirect componentPower grid

An electric locomotive harmonic suppression method comprises: performing direct current component separation of alternating current transmitted by a primary side of a traction transformer, and obtaining first direct current components and second direct current components of harmonic currents with the preset number of times of the alternating current; employing a PI regulator to generate a harmonicvoltage regulating variable according to the first direct component and the second direct current component of each harmonic current of the alternating current; performing overlapping of the harmonicvoltage regulating variable and an output fundamental wave voltage of a grid-side converter to obtain a target output voltage of the grid-side converter, and outputting a control instruction corresponding to the target output voltage to control the grid-side converter to generate a compensation current so as to offset harmonic currents included in the alternating current. Harmonic currents in a high-voltage electric network are subjected to suppression at a secondary side of a traction transformer, and compared to a current electric locomotive harmonic suppression method, the electric locomotive harmonic suppression method is more flexible in realization and is higher in reliability and safety.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Anti-loosening thread structure

InactiveCN103322007AImprove the coordination effectIncrease self-locking abilityNutsBoltsEngineeringScrew thread

Owner:新疆德坤建材有限责任公司

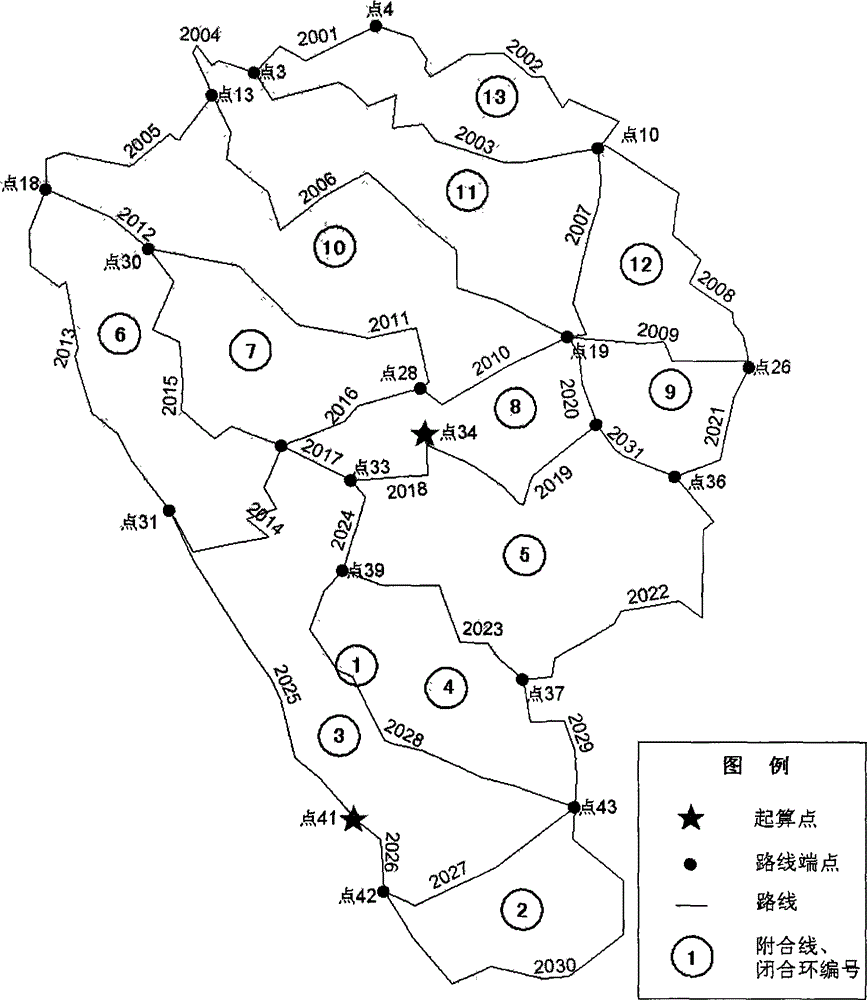

Generation algorithm of least independent closed loops and shortest annexed lines for leveling network

The invention provides a generation algorithm of least independent closed loops and shortest annexed lines for a leveling network. The algorithm includes the step of using ends of each leveling line as nodal points and other middle points as transitional points; storing the leveling lines in a two-dimensional array; distinguishing the different lines identical in nodal point and cumulative-sum distance; uniformly numbering nodal points of the leveling network; dividing the lines into independent connected sub-networks according to the nodal point adjacency feature, searching the sub-networks for the least independent closed loops and the shortest annexed lines; adjusting the directions of the closed loops to ensure that all loops of the leveling network are clockwise or anticlockwise. Compared with the traditional techniques, the algorithm has the advantages that the structure is simple, an algorithm idea is clear, a program developed on the basis of the algorithm runs fast, the closed loops are ensured being least, the annexed lines are ensured being shortest, the closed loops and the annexed lines are mutually independent and complete, closure conditions are omission free and non-redundant, the closed loops are all uniformly clockwise or anticlockwise, efficiency is improved, cost is saved, and synergy is achieved.

Owner:国家测绘地理信息局大地测量数据处理中心

Electric locomotive harmonic suppression method

InactiveCN107546740AImprove flexibilityImprove reliabilityHarmonic reduction arrangementAc network to reduce harmonics/ripplesEngineeringElectric network

An electric locomotive harmonic suppression method comprises: performing direct current component separation of an alternating current transmitted by a primary side of a traction transformer, and respectively obtaining a first direct current component and a second direct current component of harmonic currents with the preset number of times of the alternating current; generating a harmonic voltageregulating variable with the preset number of times through combination of a preset current reference value according to the first direct current component and the second direct current component ofeach harmonic current of the alternating current; and performing overlapping of the harmonic voltage regulating variable with the preset number of times and an output fundamental wave voltage of a grid-side converter to combine a target output voltage of the grid-side converter, and generating a corresponding control instruction according to the target output voltage to control the grid-side converter to generate a compensation current. Harmonic currents (namely harmonic currents existed in the alternating current transmitted by the primary side of the traction transformer) in a high-voltage electric network are subjected to suppression at a secondary side of a traction transformer, and compared to a current electric locomotive harmonic suppression method, the electric locomotive harmonicsuppression method is more flexible in realization and is higher in reliability and safety.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

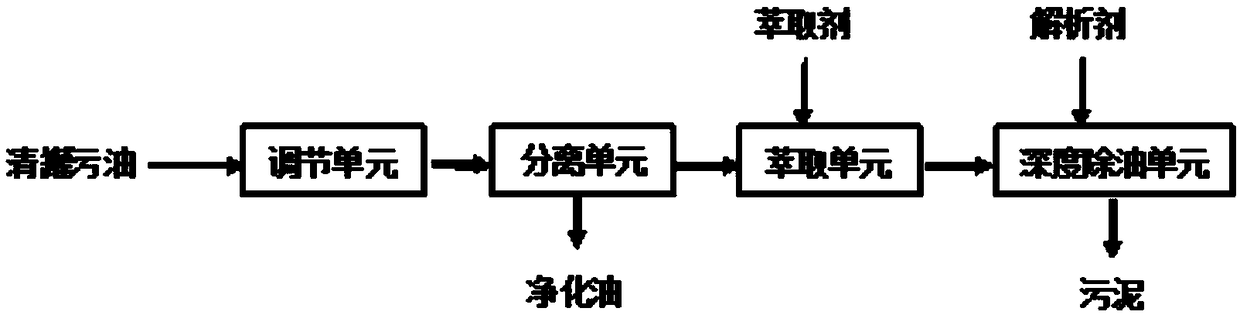

Treatment method and device of tank-cleaning sump oil

ActiveCN109437499AReduce moisture contentEasy to drySludge treatment by thermal conditioningLiquid hydrocarbon mixture productionCatalytic oxidationSewage

The invention provides a treatment method and device of tank-cleaning sump oil. The treatment method comprises the following steps: heating the tank-cleaning sump oil to 60 to 90 DEG C and carrying out adjusting treatment to obtain adjusted sump oil; separating the adjusted sump oil to obtain recycled oil, sewage and oil-containing solid impurities; carrying out extraction and oil removal treatment on the oil-containing solid impurities to obtain extracted oil and oil-containing residues; carrying out resolving, electro-catalytic oxidation and solid-liquid separation on the oil-containing residues to finish the treatment of the tank-cleaning sump oil. The invention further provides the treatment device of the tank-cleaning sump oil. By adopting the treatment method and device provided by the invention, the solid content and moisture content of recycled oil of the treated tank-cleaning sump oil are low; the oil content of the generated residues is low and the residues are easily dried.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

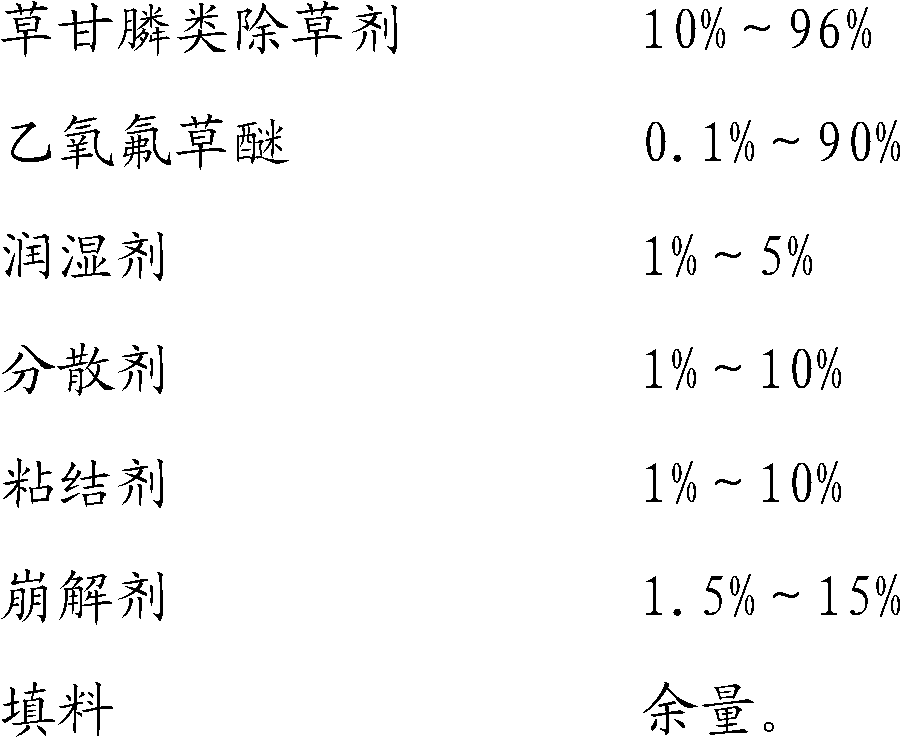

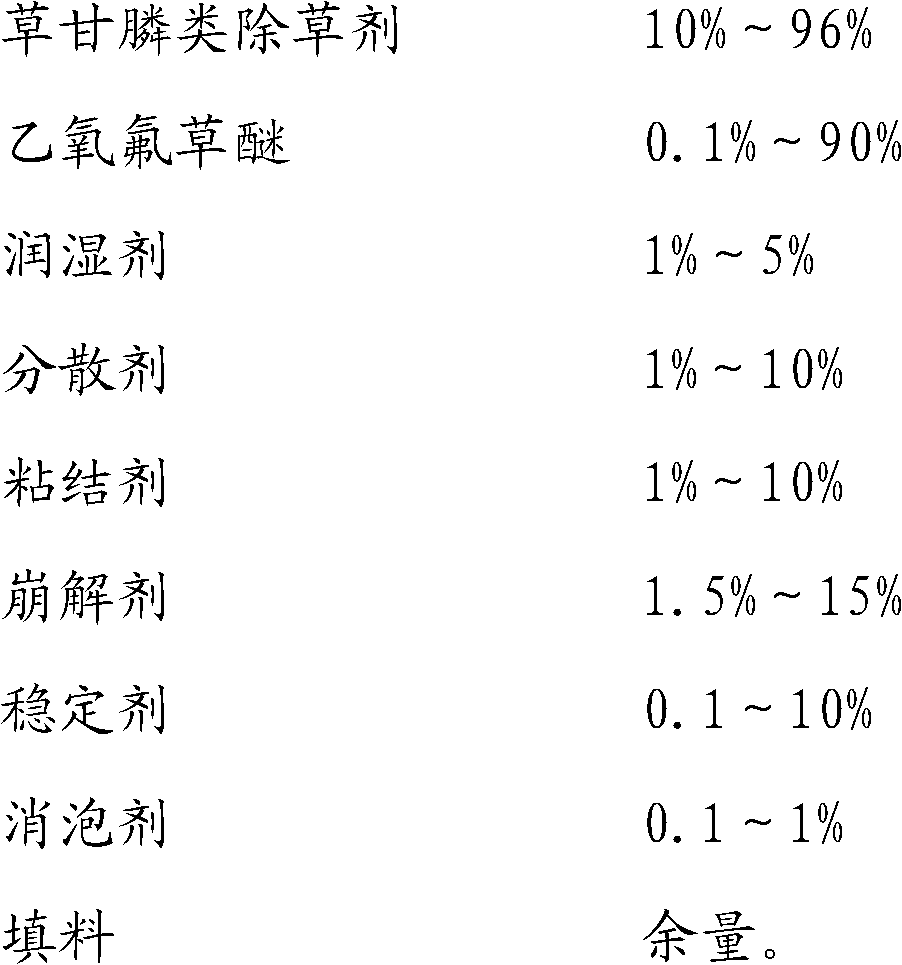

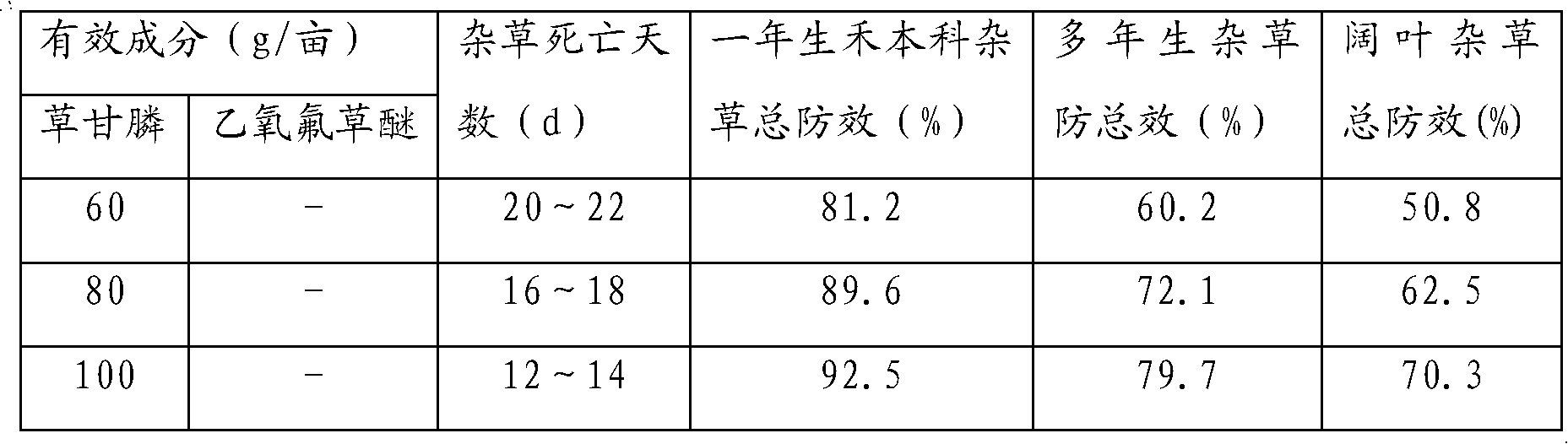

Herbicide mixture preparation

The invention discloses a herbicide mixture preparation, which includes (by wt%) glyphosate herbicide 10-96, oxyfluorfen 0.1-90, wetting agent 1-5, dispersing agent 1-10, binder 1-10, disintegrant 1.5-15, and filler for allowance. The inventive herbicide mixture preparation mixes glyphosate and oxyfluorfen according to reasonable proportions without changing their weeding activity, and realizes synergism through adding adjuvants and fillers; and it greatly improves the effect on controlling annual gramineous weeds, perennial weeds and broad-leaved weeds, while reducing the pesticide use and cost.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Efficient cultivation method for sprout vegetables of Chinese cabbages

InactiveCN106258882AHigh nutritional valueGuaranteed normal growthCultivating equipmentsSoilless cultivationResource recoverySeed treatment

The invention discloses an efficient cultivation method for sprout vegetables of Chinese cabbages. The method comprises the following steps: (1) careful selection of seeds; (2) seed processing; (3) preparation of a seedbed: loading a cultivation medium into a cultivation plate, covering the cultivation medium with gauze, closely attaching the medium to the gauze, and repeatedly spraying water to the seedbed to ensure that the medium is completely wetted; (4) seed sowing; (5) management in a seedling stage; (6) harvesting. According to the method, on the basis of cultivation of the sprout vegetables of the Chinese cabbages on an ordinary medium, the characteristics of the sprout vegetables of the Chinese cabbages are utilized, and an isolator is additionally arranged between the sprout vegetables and the medium, so that growth of the sprout vegetables is ensured, labor cost in harvesting and production resource recovery processes is also reduced, and the aim of synergism is fulfilled.

Owner:NANJING INST OF VEGETABLE SCI

Adjustable reserved hole constructing mold and constructing method

PendingCN107237494ASimple structureReasonable designPipesForms/shuttering/falseworksFloor slabStructural engineering

The invention discloses an adjustable reserved hole constructing mold and constructing method. The adjustable reserved hole constructing mold comprises an outer mold, a horizontal bottom plate and an upper covering plate, wherein the horizontal bottom plate is located at the bottom of the inner side of the outer mold, the upper covering plate is installed on the upper part of the outer mold in a covering mode, and the upper covering plate is a round covering plate; the outer mold comprises a vertical cylinder, a horizontal base plate and an annular covering opening; and an eccentric hole is formed in the horizontal bottom plate for passing through of installed pipelines. The adjustable reserved hole constructing method comprises the following steps of step 1, supporting formwork of a cast-in-place slab; step 2, surveying a line of the pipeline installing position; step 3, fixing of the outer mold; step 4, constructing of the cast-in-place slab; step 5, installing of the horizontal bottom plate; step 6, installing of the pipeline; and step 7, sealing and blocking of a hole opening. According to the adjustable reserved hole constructing mold and constructing method, design is reasonable, construction is simple and convenient, and the using effect is good; and the position of through-floorslab pipeline can be adjusted through the horizontal bottom plate with the eccentric holes to guarantee installing precision of the pipeline, and the problems, existing in current reserved hole construction, that working process is complex, potential safety hazards exist in high altitude formwork supporting, and sealing and blocking quality of the hole opening is hard to be guaranteed can be effectively solved.

Owner:陕西建工第十一建设集团有限公司

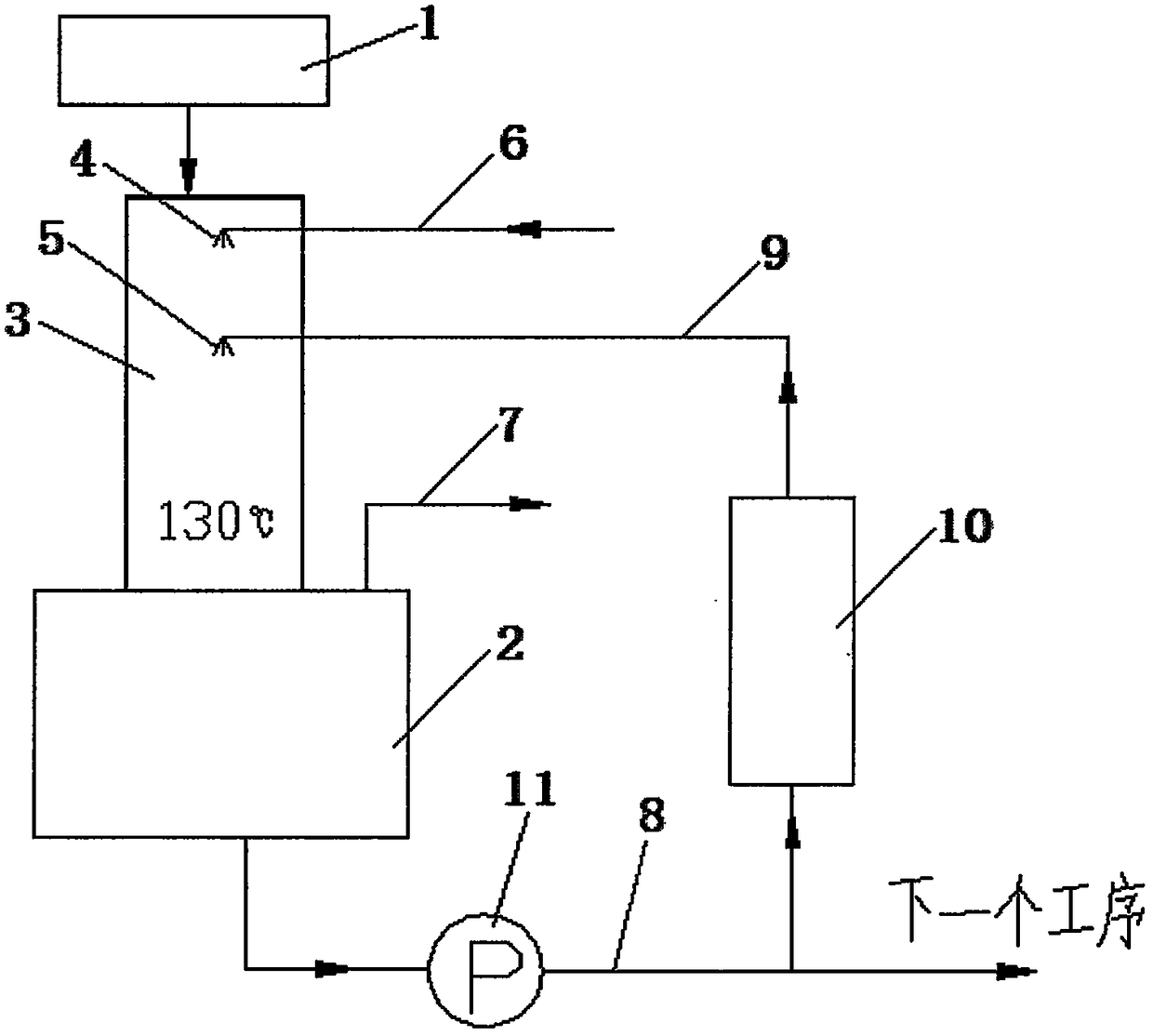

Cooling device and method for preparation of HDI by gas phase process

InactiveCN108246050AReduce the temperatureAvoid cloggingGas treatmentDispersed particle separationChlorobenzeneGas phase

The invention provides a cooling device for preparation of HDI by a gas phase process. The cooling device includes a spray condensation area disposed between a reactor and a reaction collector, a first nozzle is disposed at the upper part of the spray condensation area, the first nozzle is connected to a chlorobenzene conveying pipe, chlorobenzene is sprayed in the spray condensation area throughthe first nozzle to cool and absorb HDI prepared by the reactor, so that HDI can be separated from other gaseous substances, the reaction collector is equipped with a gas outlet pipe and a drain pipe,and the drain pipe sends chlorobenzene containing HDI to a next procedure. Compared with the traditional technology, the device and method provided by the invention can save energy, achieve more thorough absorption of HDI by chlorobenzene, and reduce by-product generation, thus increasing the product yield, are beneficial to normal running of the reaction, also play a cooling role, prolong the normal production time, and reach the purpose of synergy.

Owner:重庆长风生物科技有限公司

Synergetic bisultap

InactiveCN1408225AImprove adhesionImprove permeabilityBiocideAnimal repellantsFatty alcoholPOLYOXYETHYLENE ETHER

The synergetic bisultap is prepared by diluting bisultap with clear water to concentration of 10-35 % and mixing with alkyl aryl polyoxyethylene ether containing emulsifier and / or fatty alcohol polyoxyethylene ether containing emulsifier and has a ratio between the diluted bisultap and emulsifier of 1 to 0.00005-0.002. The addition of the alkyl aryl polyoxyethylene ether containing emulsifier and / or fatty alcohol polyoxyethylene ether containing emulsifier can increase the adhesion and penetration of the bisultap on crop greatly and raise the utilization of bisultap.

Owner:JIANGSU TIANRONG GROUP

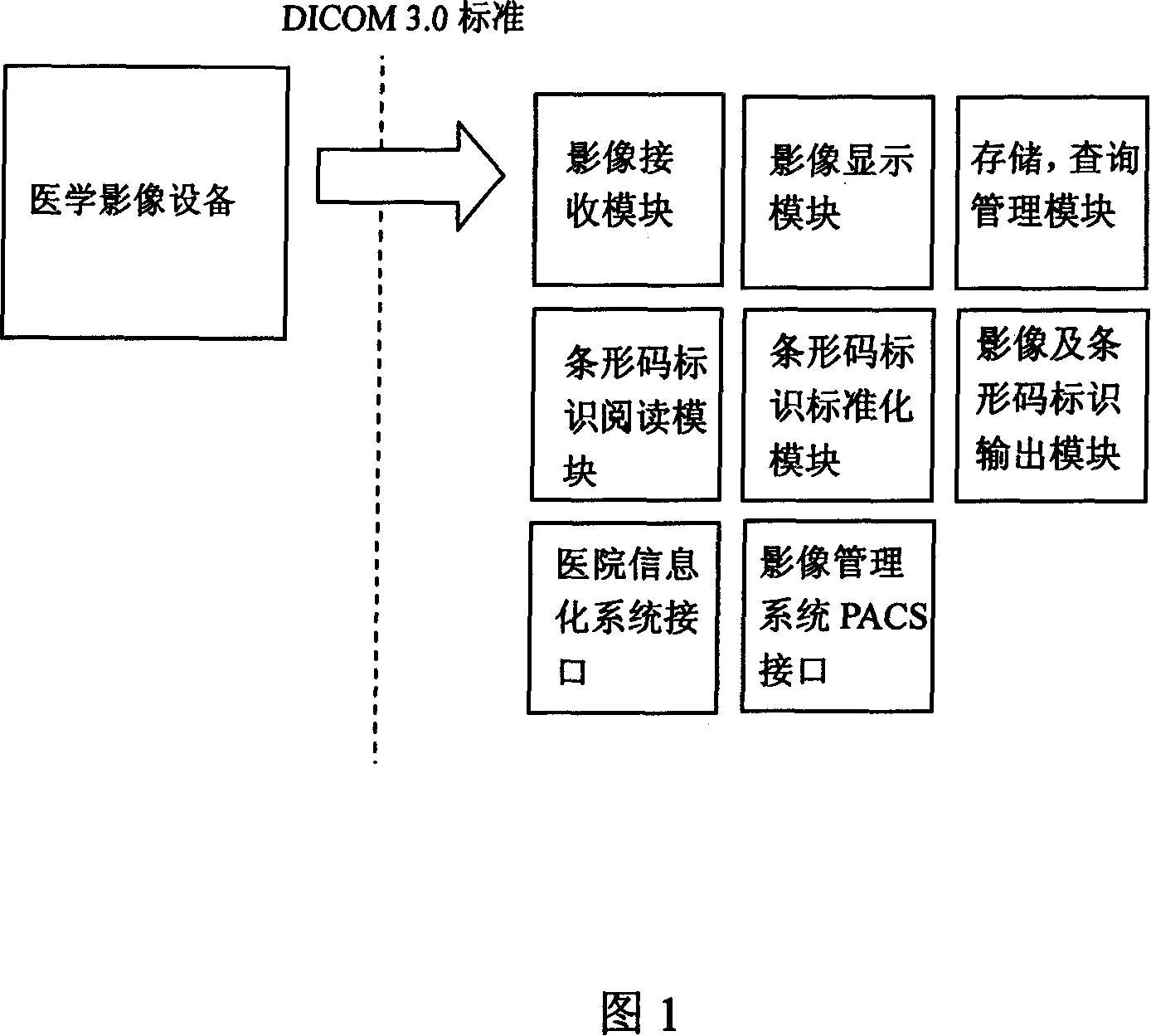

Management method of biological material products transplanted into physical body

InactiveCN101086748ATo achieve the purpose of increasing efficiencySpecial data processing applicationsHuman bodyMedical equipment

The biological material planted to human body is made through medical video equipment, video receiving module, video display module, barcode reading module, barcode standardization module, video and barcode output module, hospital information system interface, storage inquiry management module, video management system PACS interface for the management of biological material planted to human body. It is convenient for management and visual in nature.

Owner:SHANGHAI EBM MEDICAL INFORMATION SYST

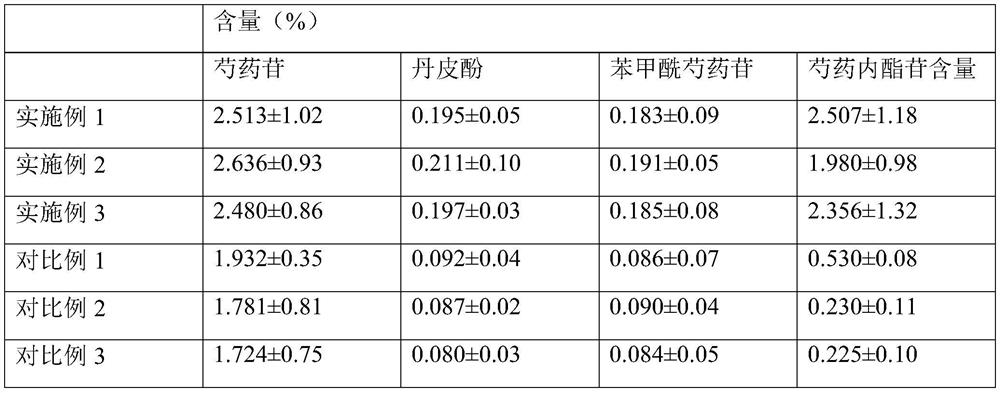

Processing method of radix paeoniae alba and radix paeoniae alba processed product

The invention relates to a processing method of radix paeoniae alba and a radix paeoniae alba processed product. The method comprises the following steps: step 1, selecting fresh radix paeoniae alba, cleaning the fresh radix paeoniae alba, and removing heads, tails and fibrous roots; step 2, soaking the cleaned radix paeoniae alba with water for 3-6 hours; step 3, placing the soaked radix paeoniae alba in a steaming container, and steaming the radix paeoniae alba in the steaming container; and step 4, taking out the steamed radix paeoniae alba, removing the skin, slicing the steamed radix paeoniae alba without skin, and naturally airing the radix paeoniae alba slices to obtain the radix paeoniae alba processed product. The radix paeoniae alba processed product contains paeoniflorin, and the mass content of the paeoniflorin is greater than or equal to 2.4%. According to the radix paeoniae alba processed product prepared by the method, the effective components are obviously improved.

Owner:河北旭宇金坤药业有限公司

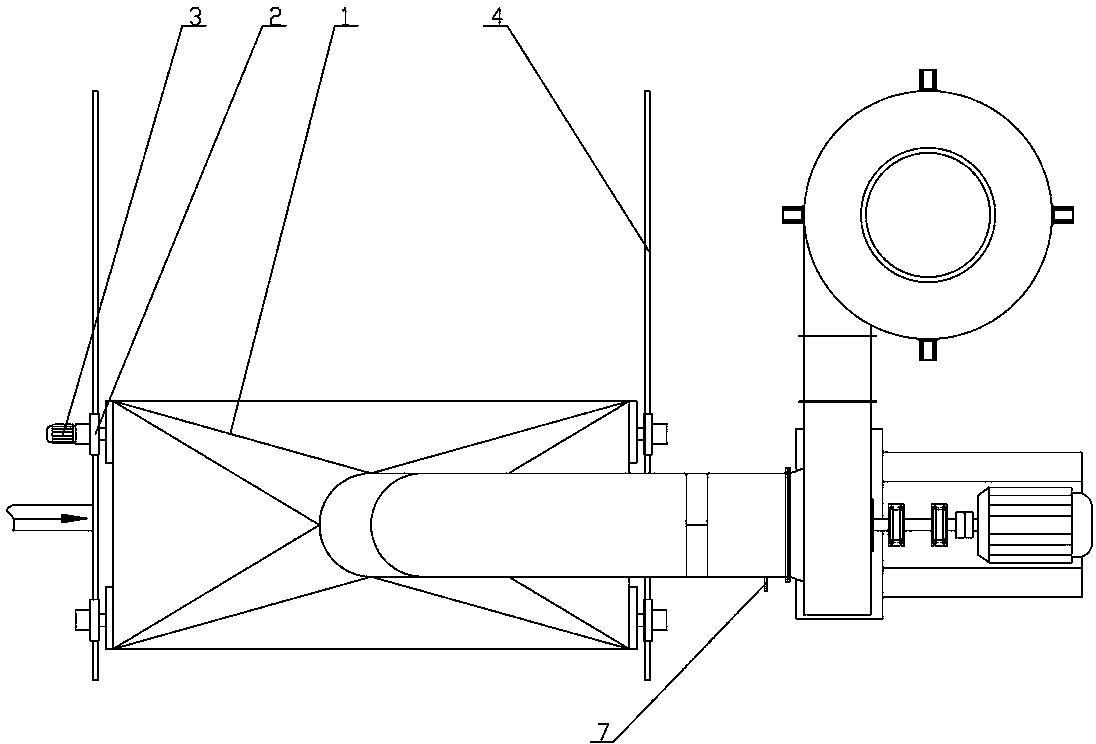

Charging automatic control system of boiling type pith-removing machinery

InactiveCN104597830AEasy to install and connectRun smoothlyProgramme control in sequence/logic controllersAutomatic controlElectro hydraulic

The invention discloses charging automatic control system of boiling type pith-removing machinery. A current sensor is mounted on a motor of the boiling type pith-removing machinery; a material blanking baffle plate is arranged in a bagasse blanking hole of a bagasse conveyor belt before the bagasse enters the boiling type pith-removing machinery; the baffle plate is driven by an electric hydraulic pushing rod; a monitoring system is mounted above the bagasse blanking hole and a spiral blade of the boiling type pith-removing machinery; a PLC (programmable logic controller) is mounted in an operating room, and connected with the display screen; the current sensor is used for transmitting a current value signal of the boiling type pith-removing machinery to the PLC; after being processed by an inner order of the PLC controller, the signal is output to control a motor of the electric hydraulic pushing rod to operate, so that the electric hydraulic pushing rod is driven to work; the opening degree of the blanking baffle plate is regulated to control amount of the bagasse of the bagasse blanking hole, so that the normal dispersing and turning work of the pith-removing machinery to the bagasse is guaranteed; the monitoring system is mounted, so that the operation staff can know the conveying state of the bagasse and the workings tate of the boiling type pith-removing machinery.

Owner:GUANGXI YUEGUI GUANGYE HOLDINGS CO LTD

Method for electrolyzing out aluminum two-man ladle through baking

The invention discloses a method for electrolyzing out an aluminum two-man ladle through baking. The method comprises the steps that a two-man ladle is lifted to a two-man ladle frame through a crown block at first, and cooled carbon residues are poured into the two-man ladle for bedding; a newly swap-out anode scrap is lifted into the two-man ladle through the crown block after being placed and cooled to be 200 DEG C and is covered with a two-man ladle cover plate, and the situation is kept for 90+ / -30mins; the two-man ladle cover plate is opened at last, the other newly swap-out anode scrap is lifted into the two-man ladle through the crown block after being placed and cooled to be 400+ / -50 DEG C and is covered with the two-man ladle cover plate, and baking at 500 DEG C is conducted for 24+ / -1 hours. According to the method for electrolyzing out the aluminum two-man ladle through baking, the existing high temperature conditions of an electrolytic plant are utilized, an electrolytic bath is used for swapping out preheating of the anode scraps to bake the ladle, high efficiency and low consumption are achieved, work load of workers for gathering fuel is greatly reduced, and the environment-friendly and safe operation is really achieved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

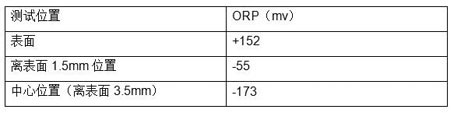

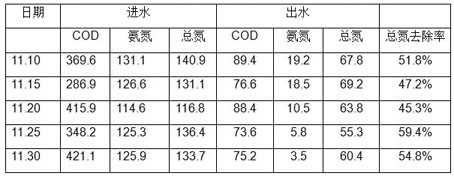

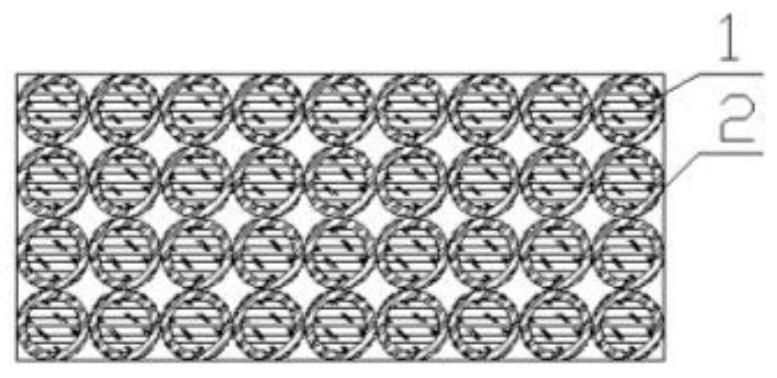

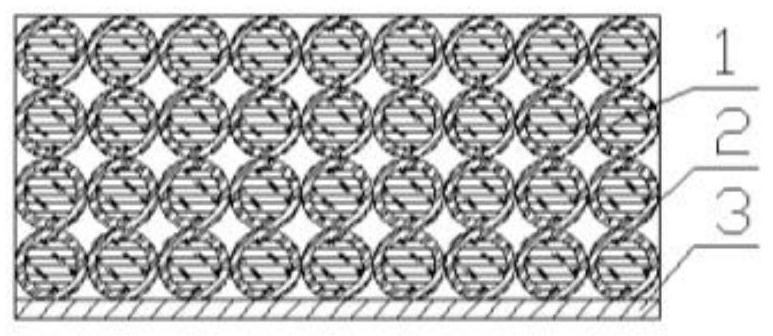

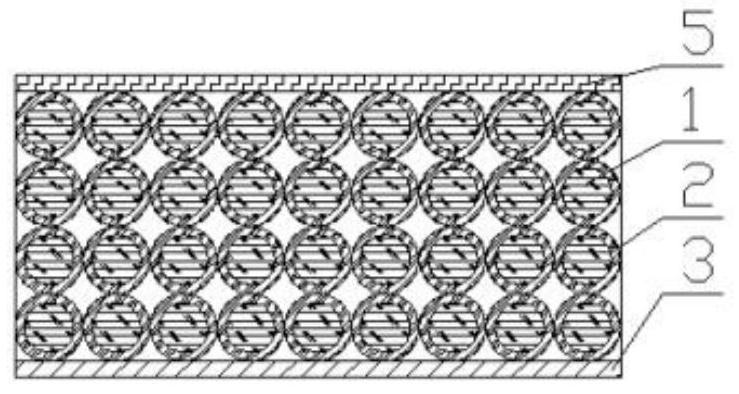

Modified polyurethane carrier and preparation method thereof

ActiveCN113045797AIncrease the attachment surfaceTo achieve the purpose of increasing efficiencyWater treatment parameter controlWater contaminantsCellulosePolymer science

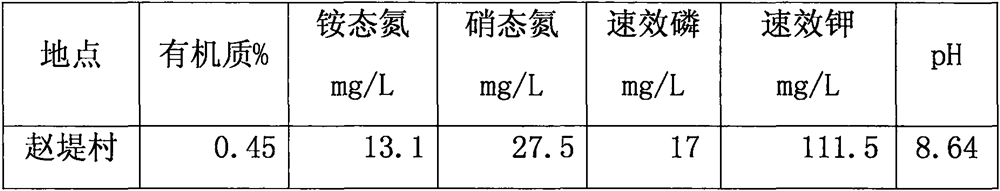

The invention provides a modified polyurethane carrier and a preparation method thereof, and aims to solve the technical problems of small specific surface area, poor adsorbability, poor toxicity impact resistance, poor fluidization property after biofilm formation and the like of the existing suspension carrier. The preparation method of the modified polyurethane carrier is characterized by comprising the following steps: S1, preparation of a coating modification liquid: mixing the following raw materials in parts by weight: 30 to 50 parts of powdered activated carbon, 3.0 to 8.0 parts of hollow glass micro-beads, 0.5 to 1.5 parts of riboflavin, 0.5 to 2.0 parts of L-cysteine, 1.0 to 3.0 parts of reduced iron powder, 1 to 4 parts of sodium carboxymethyl cellulose, 200 to 450 parts of water, 0.5 to 2.0 parts of an organic silicon wetting agent, and 8 to 20 parts of acrylic emulsion. and S2, preparation of a modified polyurethane carrier: infiltrating the outer surface and the inner hole surface of porous polyurethane foam with the coating modification liquid, and curing to obtain the modified polyurethane carrier.

Owner:无锡映川环境技术有限公司

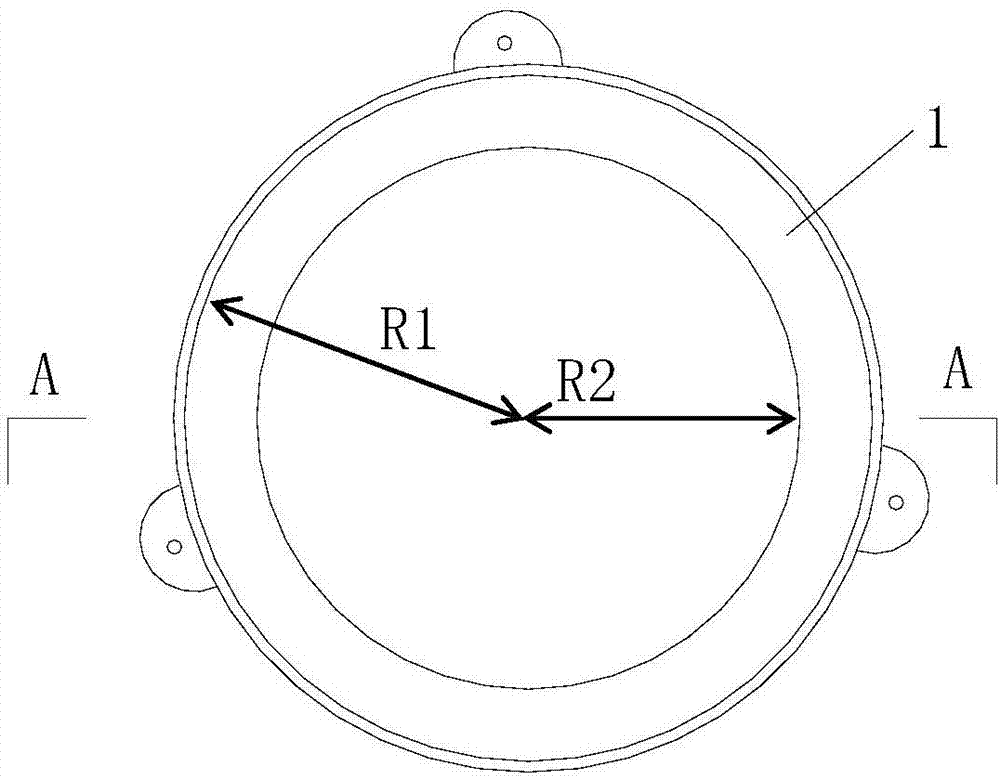

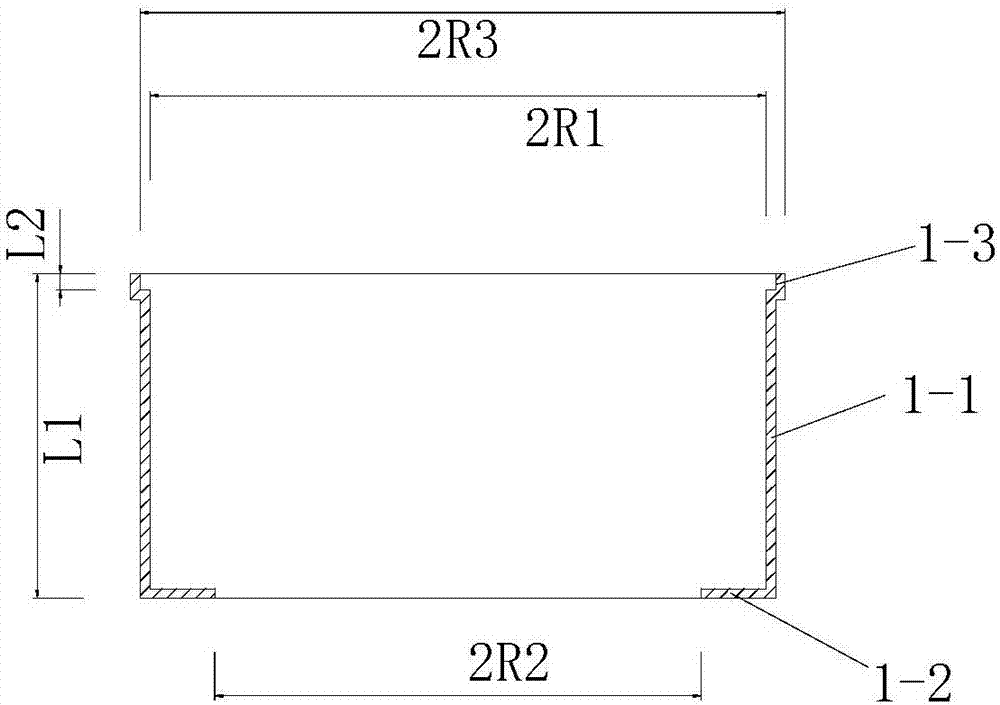

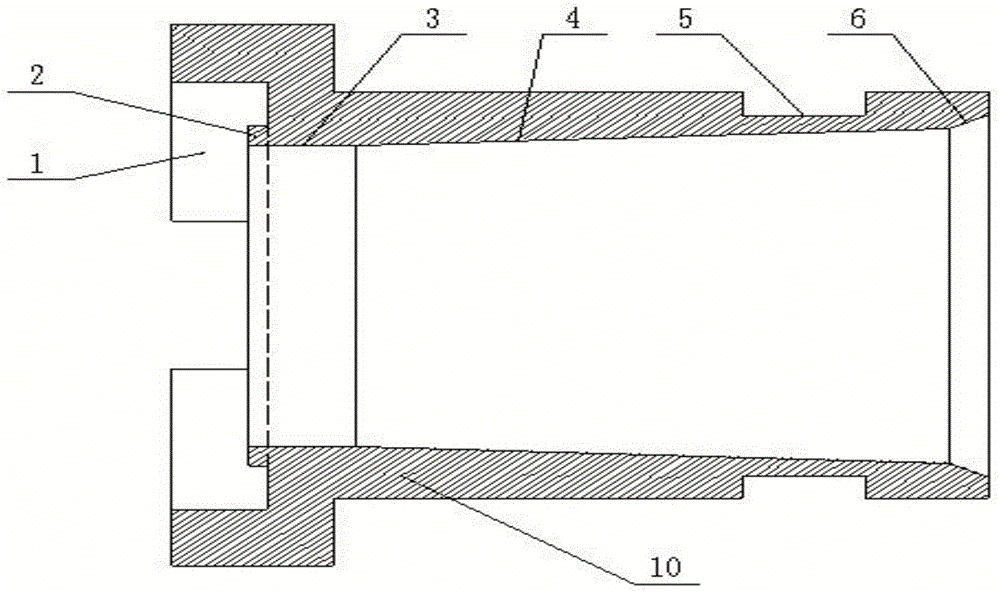

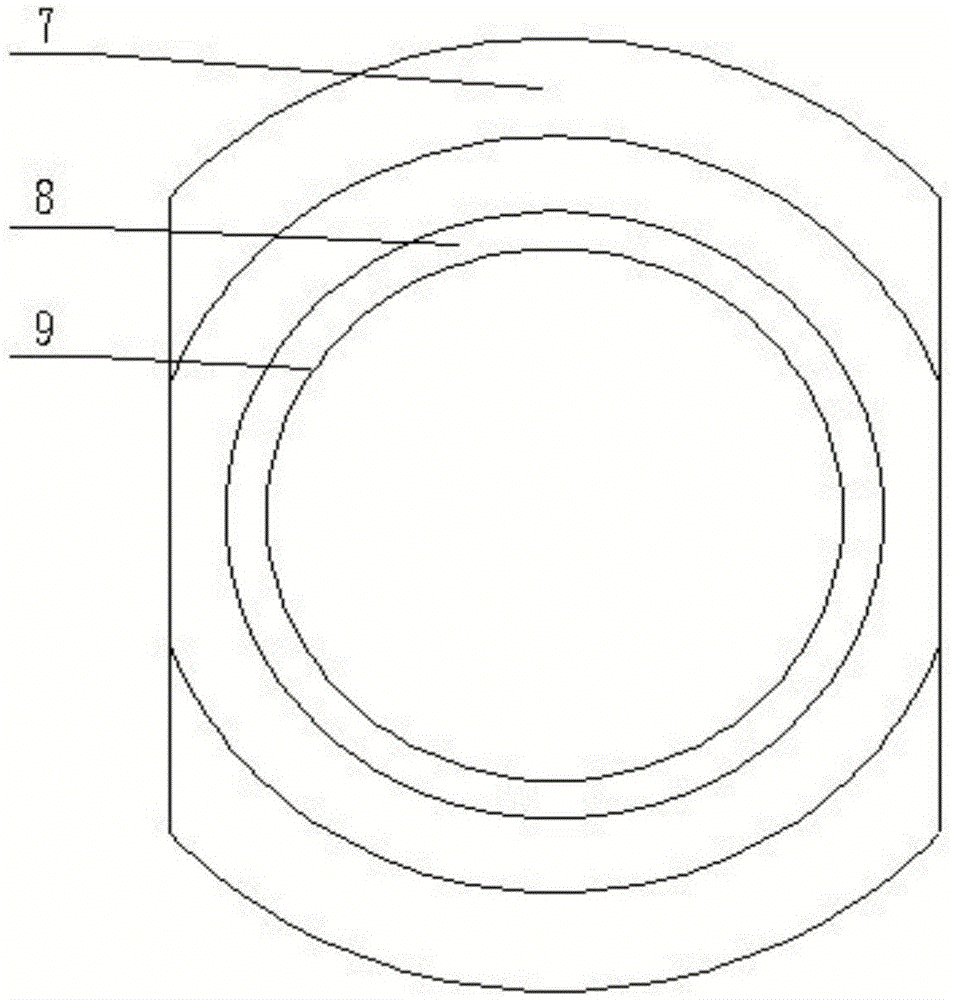

Three-section honing material-pressing sleeve for automotive piston ring

InactiveCN105538124AReduce weightTo achieve the purpose of increasing efficiencyHoning machinesPiston ringEngineering

A three-section honing material-pressing sleeve for an automotive piston ring mainly consists of a positioning check ring (1), a transition boss (2), a first-section bell mouth (6), a second-section bell mouth (4), a third-section pressing-in opening (3), a process slot (5) and a material-pressing sleeve body (10); the interior of the material-pressing sleeve is made into three sections, so that the charging difficulty of operating personnel is greatly reduced; the transition boss (2) is manufactured at the bottom part of the material-pressing sleeve and is flush with a cylinder sleeve opening to play a part of transition; meanwhile, the process slot (5) is processed at a proper position of an excircle surface of the material-pressing sleeve, and thus not only is the weight of the material-pressing sleeve reduced but also the operation is convenient, therefore production efficiency is increased, and the goal that benefit of an enterprise is increased is achieved.

Owner:李陶胜

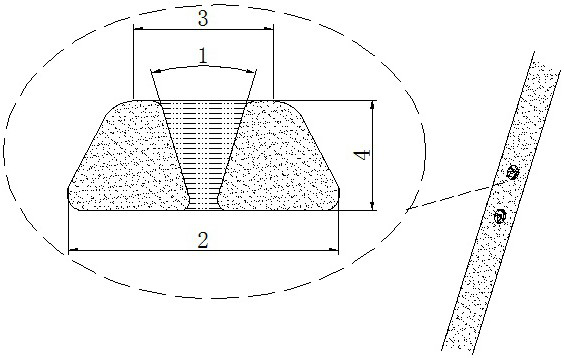

Preparation method of trapezoidal sectional type hollowed-out low-yield solder strip and photovoltaic module thereof

PendingCN111628026AReduce crackingReduce shading areaFinal product manufacturePhotovoltaic energy generationElectrical batteryStructural engineering

The invention discloses a preparation method of a trapezoidal sectional type hollowed-out low-yield solder strip and a photovoltaic module thereof. The method comprises the following steps: (1) according to the broken grid, positive / negative width and length and model of grid lines of a battery piece, determining the trapezoidal and hollow-out conical sizes, including the hollow-out conical degree, the bottom width, the top width and the total thickness, of a solder strip; (2) determining the optimal hollowed-out conical degree by using the hollowed-out distance of the solder strip as two holes per broken grid and the hollowed-out conical degree as 30 degrees, 45 degrees and 60 degrees respectively for orthogonal experiment evaluation test; (3) sequentially carrying out roller calendering,trapezoidal grinding tool wire drawing and taper hole treatment, by an perforating machine, on the solder strip with the size determined according to the step (1) and the step (2) to obtain a trapezoidal solder strip; and (4) annealing and tin-plating the trapezoidal solder strip obtained in the step (3). The method has the beneficial effects that the yield limit bottleneck of other solder stripsis broken through, the yield is reduced, and subfissure of the photovoltaic module is reduced.

Owner:江苏太阳科技股份有限公司

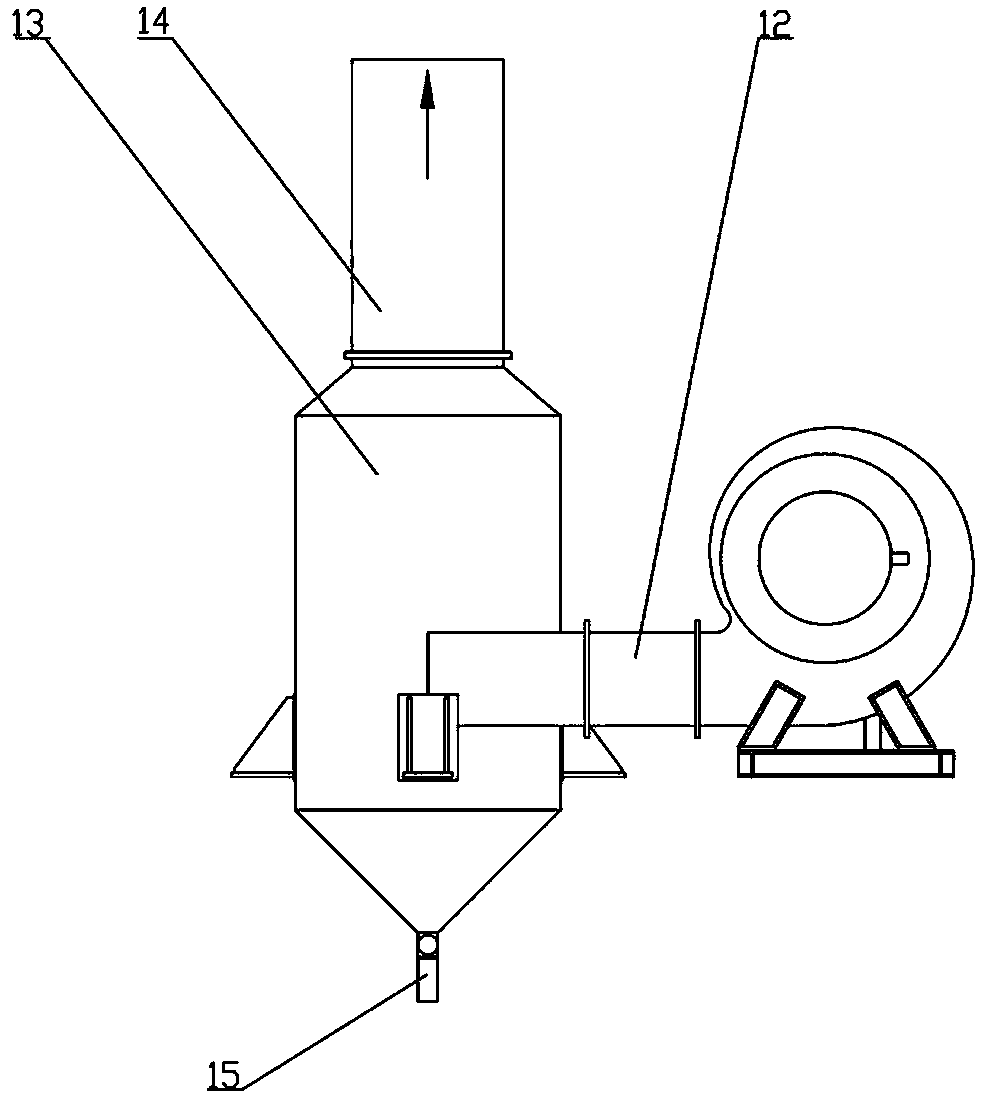

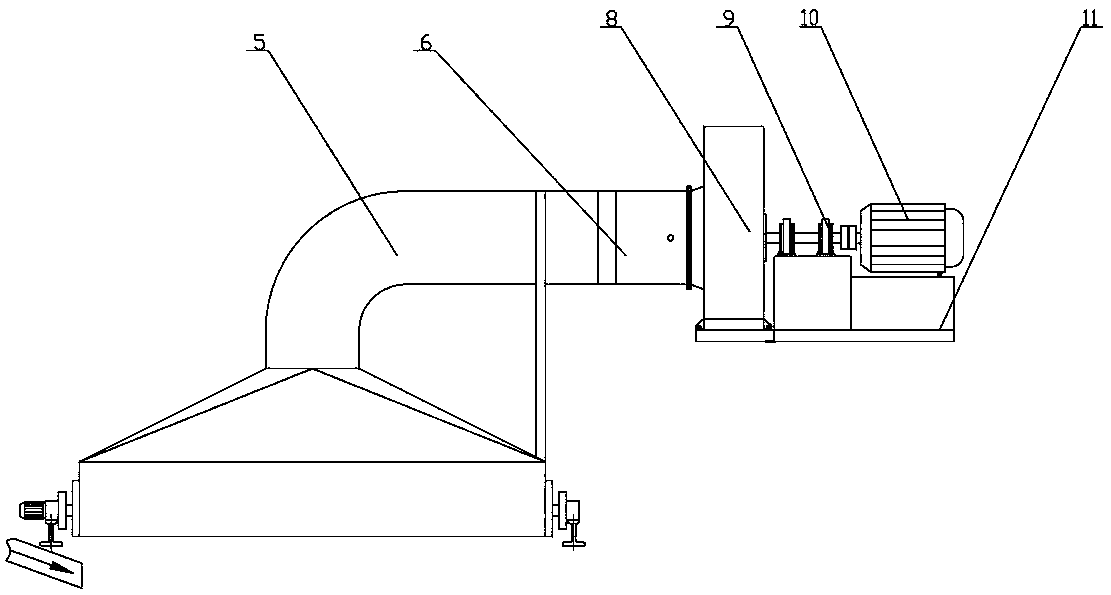

Device and method for collecting waste gas during water quenching of liquid slag

ActiveCN102350142BGood environmental effectReduce the amount of fresh waterDispersed particle separationDirt cleaningQuenchingExhaust pipe

The invention relates to a device and a method for collecting waste gas during water quenching of liquid slag, and the method and device provided by the invention are used for overcoming the technical difficulty in collection of waste gas during water quenching of the liquid slag. The waste gas is collected by a mobile gas collection cover; the waste gas passes through a mobile gas exhaust pipe and a fixed gas exhaust pipe, is cooled and condensed by atomized water sprayed out of a spiral atomization nozzle, and then is conveyed into a washing fan; the condensed waste gas enters a water and gas separation barrel at a flow speed of 30 meters per second after being cooled; under the action of a centrifugal force, condensed water and dust move downwards along the wall of the barrel so as to be separated and purified; purified clean air is emptied by virtue of an air exhaust barrel; the condensed water and the dust are discharged by virtue of a discharge pipe arranged at the bottom of the barrel body; and the separated sewage is conveyed into a clarification tank for clarification and reused, therefore, the blank of collection of the waste gas during water quenching of the liquid slag in China is filled, and the device has the advantages of conservation of water resources, good environmentally-friendly effect, simplicity and convenience in operation and improvement on working environment.

Owner:HENAN YUGUANG GOLD & LEAD

Technology for sowing and cultivating broom corn millet before winter

PendingCN112913604AImprove yield and qualityPromote Diversified DevelopmentFertilising methodsCereal cultivationPesticideEnvironmental geology

The invention discloses a technology for sowing and cultivating broom corn millet before winter. The technology includes the steps of preparing before sowing, selecting land, selecting flat land which is deep in soil layer, fertile in soil texture, strong in water and fertilizer retention capability and good in drainage and ventilation, selecting wheat stubble without using high-residual pesticide and corn stubble and potato stubble which are good in cultivation condition as previous stubbles, and avoiding continuous cropping and alternate cropping; selecting varieties and treating seeds; sowing the seeds; conducting field management; controlling diseases, pests and birds; and in the jointing and booting stage of the broom corn millet, spraying 40-50 kg / mu of a 0.2%-0.3% monopotassium phosphate aqueous solution on leaf surfaces of plants in sunny days, and the situation that the broom corn millet can absorb and utilize the solution as soon as possible is guaranteed. According to the technology for sowing and cultivating the broom corn millet before winter, the major problems that sowing in spring is dry and less in rain, the emergence rate is low, late-maturing varieties cannot be mature and the like can be effectively solved, meanwhile, the yield and quality of the broom corn millet can be improved, diversified development of the broom corn millet is enhanced, and the income of farmers is effectively guaranteed.

Owner:GUYUAN BRANCH NINGXIA AGRI & FORESTRY SCI

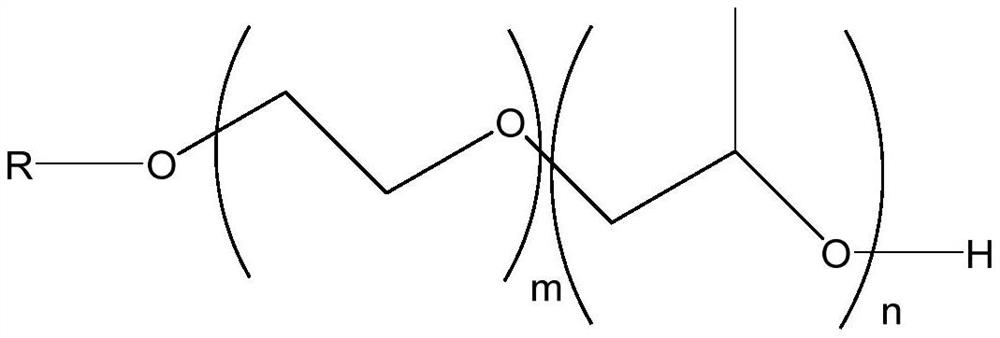

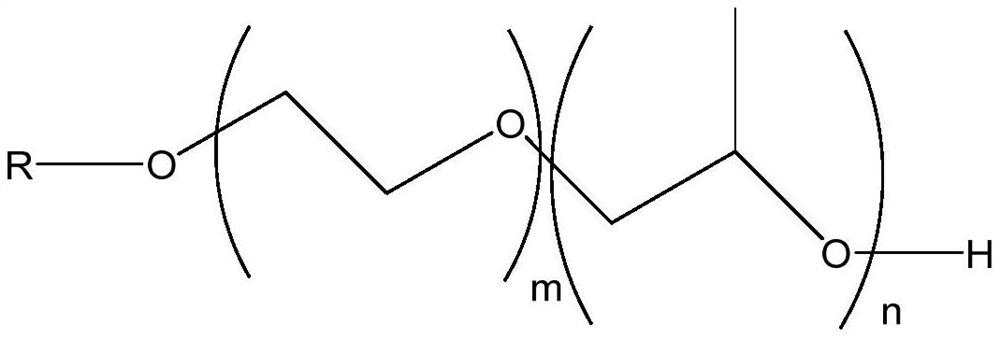

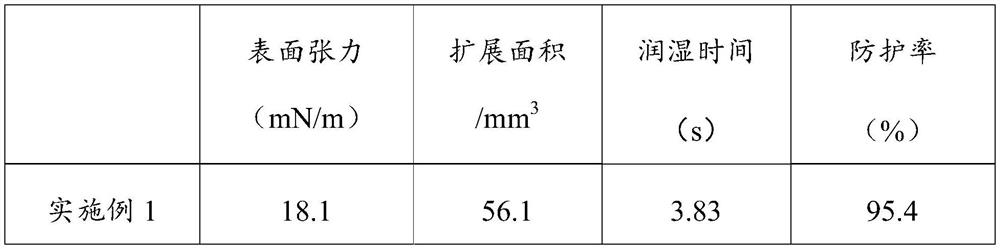

Fluorine-containing pesticide synergist as well as preparation method and application thereof

PendingCN114732011AImprove wetting propertiesAssist in absorption and conductionBiocideAnimal repellantsPesticide synergistsPESTICIDE ADJUVANTS

The invention relates to the technical field of pesticide adjuvants, in particular to a fluorine-containing pesticide synergist as well as a preparation method and application thereof. According to the fluorine-containing pesticide synergist provided by the invention, the effective components of the synergist comprise perfluorononenoxy benzene sulfonate, isomeric alcohol polyoxyethylene polyoxypropylene ether and methyl oleate. After the perfluorononenoxy benzene sulfonate, the isomeric alcohol polyoxyethylene polyoxypropylene ether and the methyl oleate are compounded, an obvious synergistic effect is achieved, and the effect that the surface tension is remarkably reduced while the dosage of a medicament is reduced can be achieved; meanwhile, the effects of reducing pesticide residues, delaying formation of pesticide resistance of pests and reducing the cost are also achieved.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

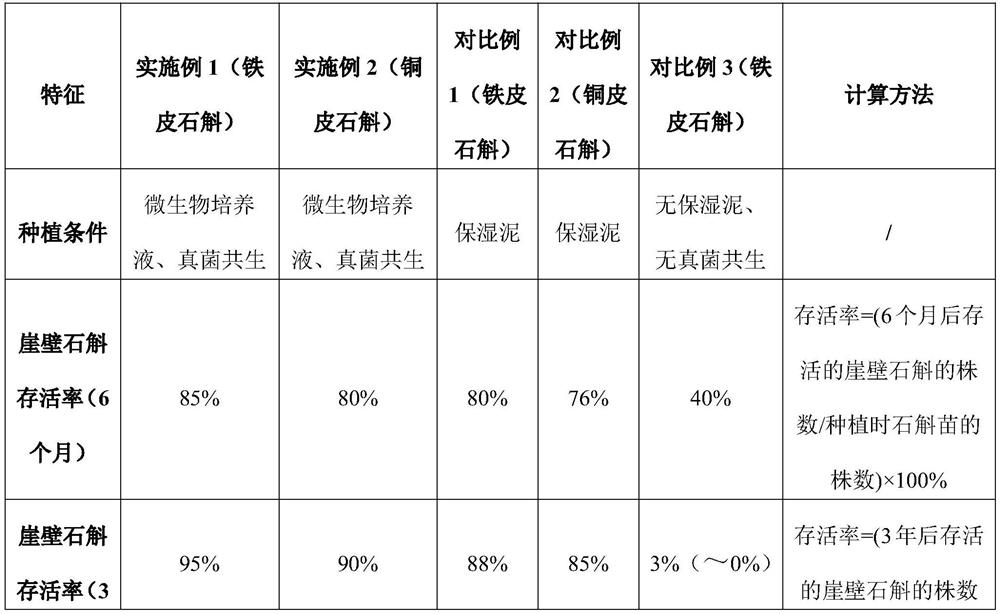

Microbial culture solution and cliff fungus cultivation and dendrobium nobile lindl symbiotic planting method thereof

ActiveCN112205239APromote growthAct as a sticky objectCultivating equipmentsMushroom cultivationBiotechnologyMicroorganism

The invention belongs to the technical field of plant cultivation, and particularly relates to a microbial culture solution. The microbial culture solution comprises rice husk soup and superphosphoricacid and can provide growth elements for natural fungi and promote growth of the natural fungi. The invention further relates to a method for carrying out cliff fungus cultivation and dendrobium nobile lindl symbiotic planting by using the microbial culture solution. Under the action of the microbial culture solution, the natural fungi can grow and propagate quickly after natural sunlight exposure and rain and dew temperature difference for one week; and under the symbiotic action of the natural fungi, dry and drought moisture preservation can be achieved in a time period in severe weather, the symbiotic action of dendrobium nobile lindl is protected, drought death is avoided, rapid growth of dendrobium nobile lindl is improved, the survival rate reaches 90%-95%, the quality is good, andthe standard of national wild dendrobium nobile lindl is met.

Owner:FUJIAN LIANCHENG GUANJIANG DENDROBIUM OFFICINALE

Molecular sieve spacing bar, manufacturing method and equipment

PendingCN113006652AImprove moisture absorptionAdd support functionDoors/windowsMolecular sieveAdhesive

The invention belongs to the technical field of glass deep processing, and discloses a molecular sieve spacing bar, a manufacturing method and equipment. A molecular sieve in the molecular sieve spacing bar is bonded into a strip-shaped object through an adhesive; the outer surface of the molecular sieve is wrapped with a layer of adhesive, and the spacing bar which takes the molecular sieve as a supporting framework and has a certain porosity is formed through mutual bonding of the adhesive; and the spacing bar is directly bonded on glass in an online manufacturing and online placing mode to form a spacing frame. According to the molecular sieve spacing bar, the moisture absorption function is added to the spacing bar, the supporting function is added to the molecular sieve, the molecular sieve and the spacing bar are combined into a whole, the existing molecular sieve filling process is omitted, and therefore the production cost is reduced; various additives can be added into the spacing bar, and various functional strips can be compounded, so that the performance of the spacing bar is improved; and the cost of the spacing bar is not higher than that of an existing lowest aluminum alloy strip, and the performance of the spacing bar is not lower than that of an existing highest-end TPS strip and TSS strip.

Owner:温州前瞻玻璃科技有限公司

A kind of complete nutrient fertilizer capable of promoting corn silking in advance and preparation method thereof

ActiveCN107673821BReduce utilizationTo achieve the purpose of increasing efficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiotechnologyFurfural

Owner:HENAN XINLIANXIN FERTILIZER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com