Treatment method and device of tank-cleaning sump oil

A treatment method and treatment device technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problem of increasing the cooling load of diesel oil and residual oil, increasing energy consumption, and wasting heat sources and other issues, to achieve significant economic and environmental benefits, save disposal costs, and increase disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solutions of the present invention are now described in detail below, but should not be construed as limiting the scope of implementation of the present invention.

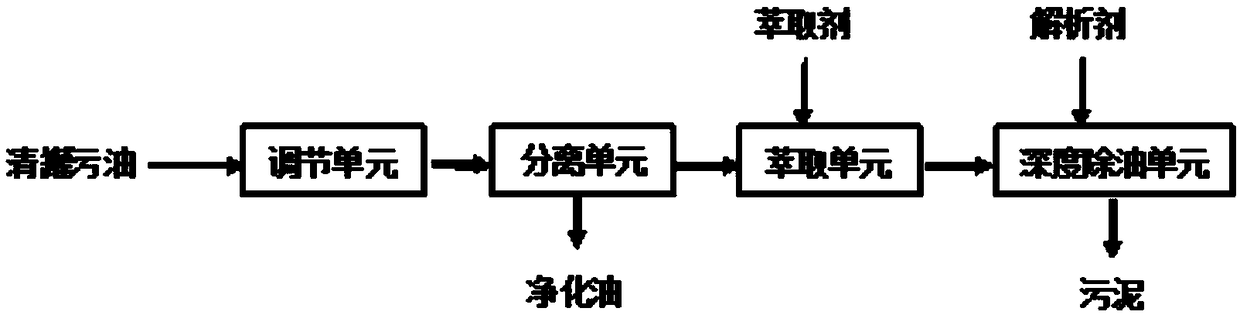

[0062] like figure 1 As shown in the figure, the present embodiment provides a tank cleaning sewage oil amount treatment device, the purification treatment device includes: an adjustment unit 1, a separation unit 2, an extraction unit 3, a deep oil removal unit 4, an extraction agent tank 5, and an analytical agent tank. 6.

[0063] The conditioning unit 1 communicates with the separation unit 2 , the separation unit 2 communicates with the extraction unit 3 , and the extraction unit 3 communicates with the deep oil removal unit 4 .

[0064] The extraction agent tank 4 is communicated with the extraction unit 3 , and the analytical agent tank 6 is communicated with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com