Charging automatic control system of boiling type pith-removing machinery

An automatic control system and boiling technology, which is applied in the field of automation systems, can solve problems such as unstable feeding, skipping of pitting machines, difficult work and high intensity, so as to improve efficiency and automation and reduce the probability of bagasse blockage , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

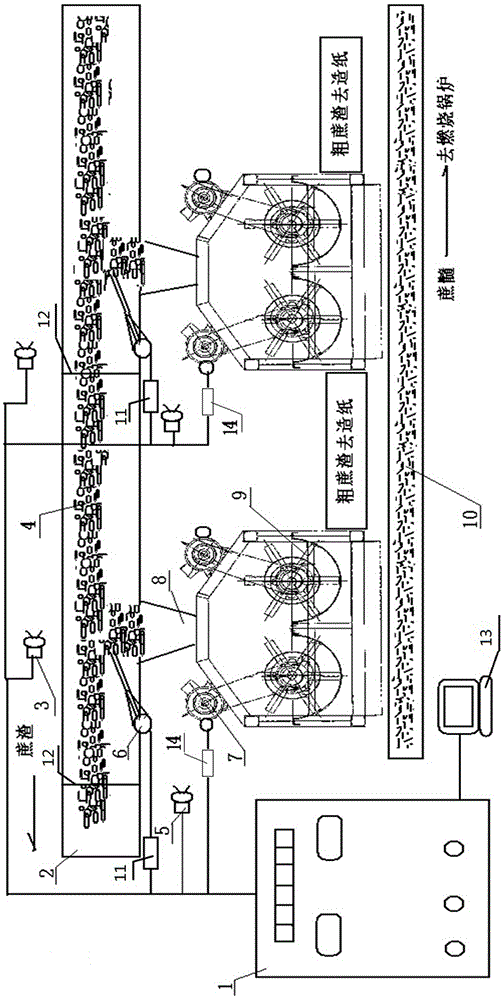

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0025] After the sugarcane is squeezed, the bagasse (4) is transported to the bagasse conveyor belt (2), combed through the adjustment baffle (12), and at the same time, the bagasse conveyor belt monitor (3) transmits the field data to the PLC controller (1), The PLC controller (1) issues instructions to control the electro-hydraulic push rod motor (11) to drive the electro-hydraulic push rod (6) to move, and push the bagasse (4) into the bagasse blanking port (8) and enter the boiling type pitting machine (9 ) to remove pitting; a current sensor (14) is installed in the drive circuit of the pitting machine motor (7), and a boiling type pitting machine monitor (5) is installed above the spiral blade of the boiling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com