Device and method for collecting waste gas during water quenching of liquid slag

A waste gas collection and liquid slag technology, applied in separation methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient production safety, low visibility in surrounding workshops, and difficult operation of personnel, so as to reduce equipment misoperation and Safety accidents, obvious environmental protection effects, and the effect of improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

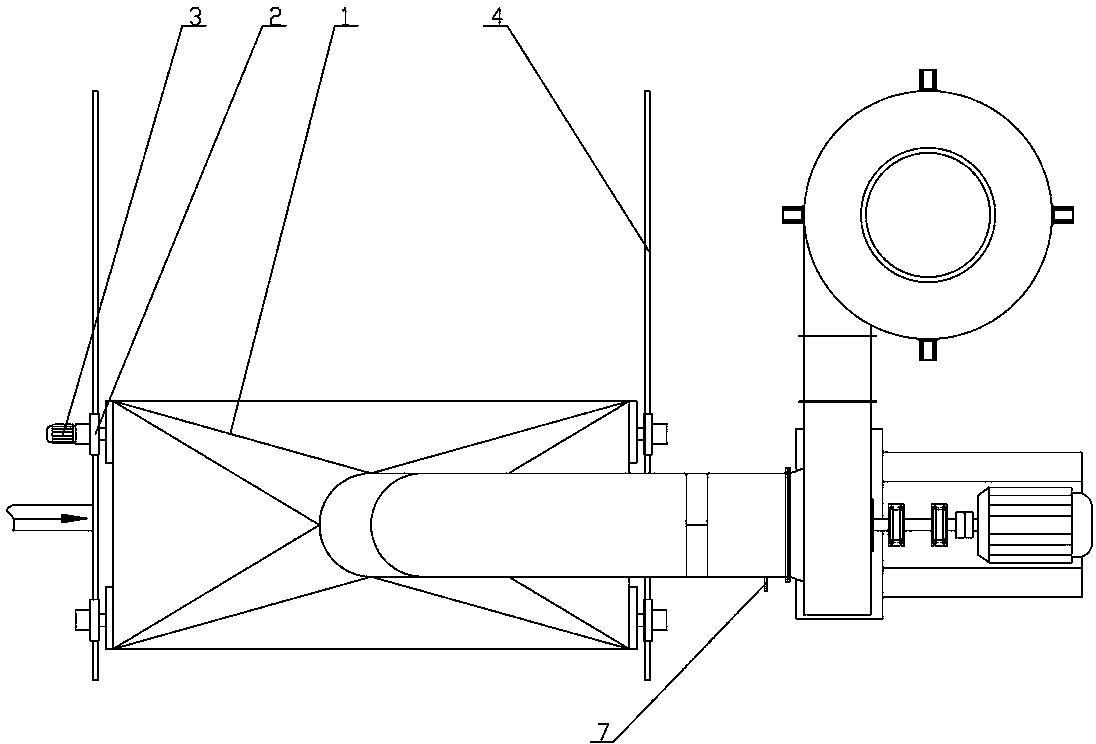

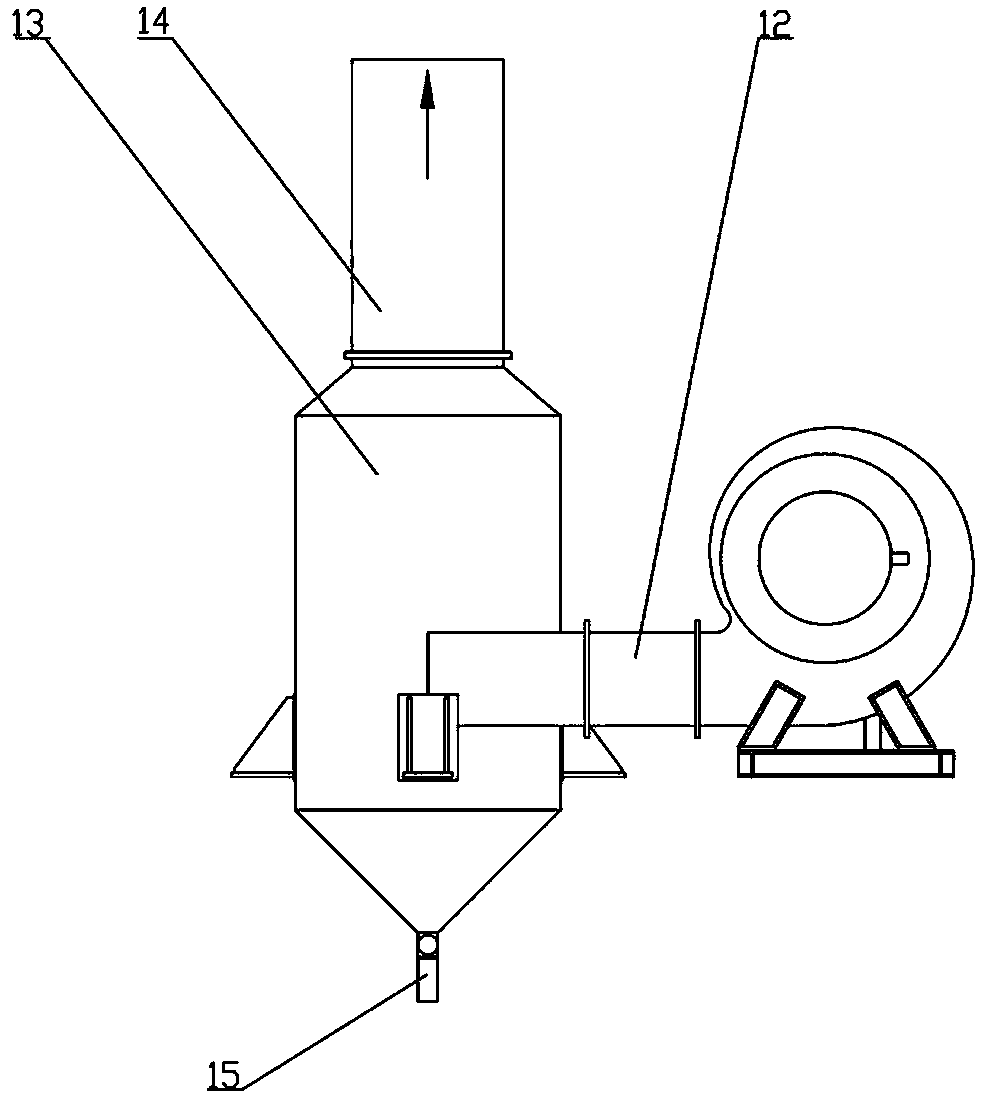

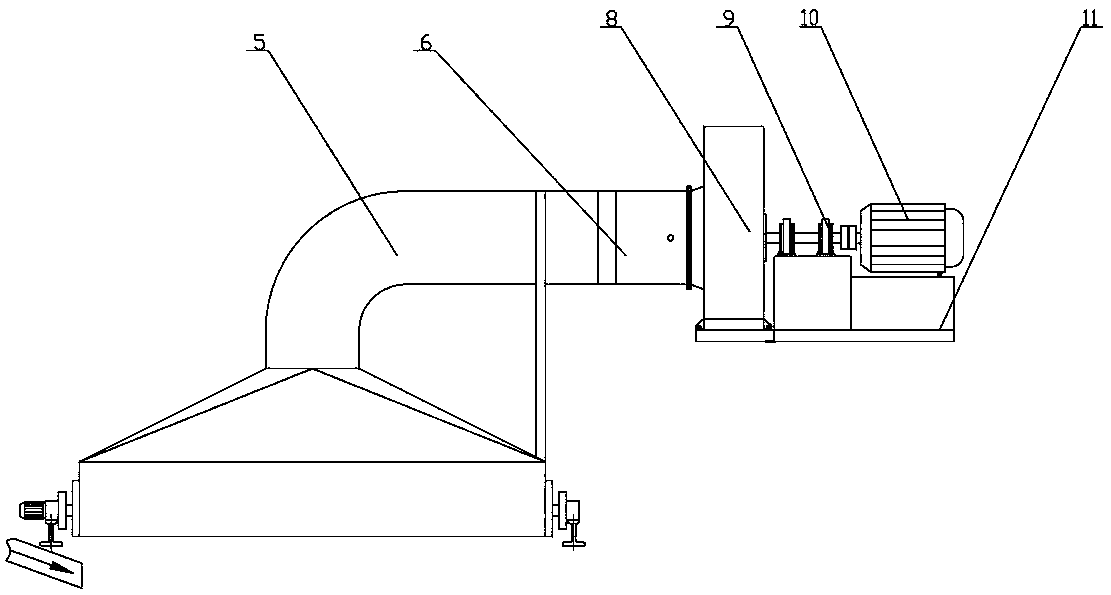

[0024] Such as figure 1 As shown, a device for collecting and treating waste gas in the liquid slag water quenching process includes a mobile gas collecting hood 1, a washing fan 8 fixed on the frame, and a water-air separation cylinder 13 connected to the washing fan 8, and is characterized in that: Four traveling wheels 2 are arranged outside the cover body at both ends of the mobile gas collecting hood 1, and the traveling wheels 2 are placed on the track 4, and the electric traveling device 3 is connected with the traveling wheels 2 at one end; the mobile exhaust pipe 5 is fixed on the mobile collecting On the top surface of the gas hood 1, one end is connected to the air outlet of the mobile gas collecting hood 1, and the other end is overlapped with the fixed exhaust pipe 6; one end of the fixed exhaust pipe 6 is overlapped with the mobile exhaust pipe 5, and the other end is connected with the washing The fan 8 is connected; the spiral atomizing nozzle 7 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com