Weight control method for braided fabric

A technology of weight control and control method, which is applied in knitting, textiles and papermaking, etc. It can solve problems affecting comfort, multiple weights, and differences in the density value of sweater pieces, so as to reduce the generation of waste pieces, reduce labor costs, and yield Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

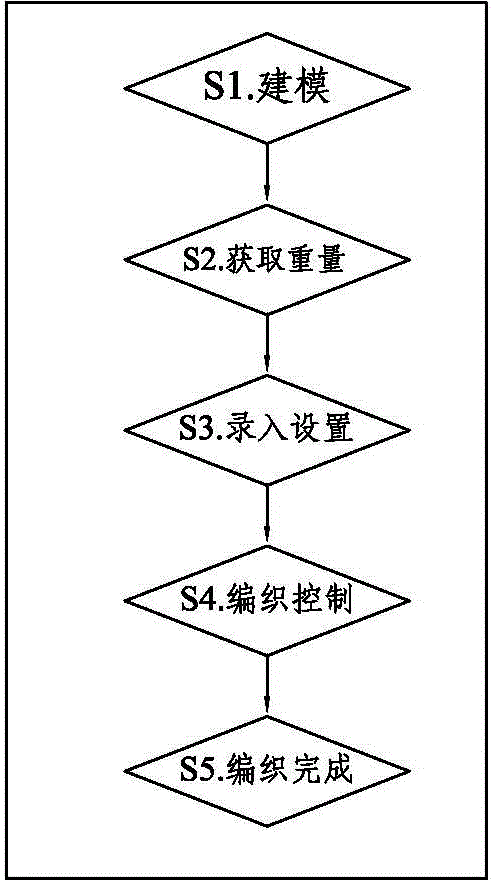

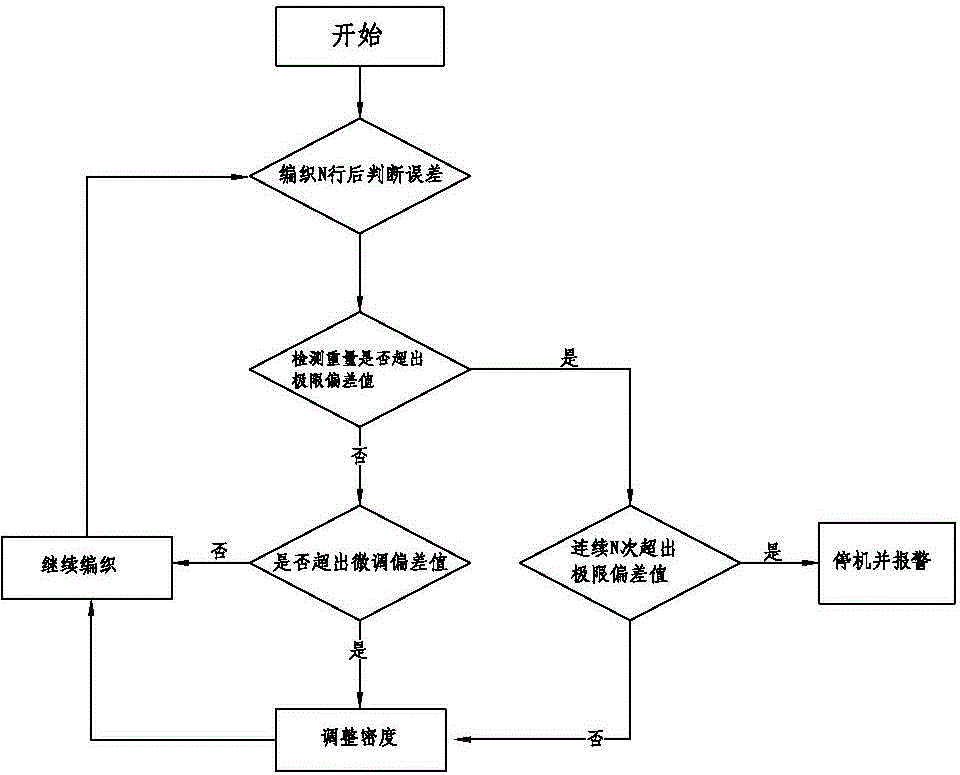

[0023] Attached below figure 1 , attached figure 2 The present invention will be described in detail.

[0024] A kind of weight control method of braid provided by the invention, this control method comprises the following steps:

[0025] S1. Modeling: establish a standard piece of braided fabric;

[0026] S2. Obtain weight: divide the standard sheet into several segments, and obtain the weight data of each segment;

[0027] S3. Input setting: input the obtained weight data into the system as the segment standard weight; and set a deviation value for the segment standard weight;

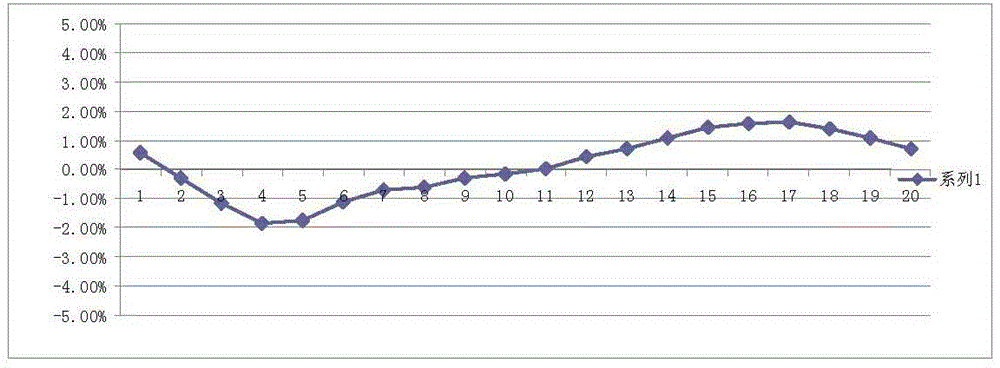

[0028] S4. Weaving control: In mass production, the weight of yarn used in each section of braided fabric is monitored, and if the weight of yarn used in the current weaving section is greater than the upper limit of the deviation value attached to the standard weight, the current knitting density value is reduced; If the yarn usage weight of the current knitting segment is less than the lower l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com