Remolded soil sample preparation device capable of controlling density through weight and air pressure combined loading

A technology of air pressure controller and combined loading, which is applied in the field of geotechnical testing in geotechnical engineering, can solve the problems of holes, uneven density of reshaped soil samples, etc., and achieve the effect of uniform soil samples, shortening the sample preparation cycle, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

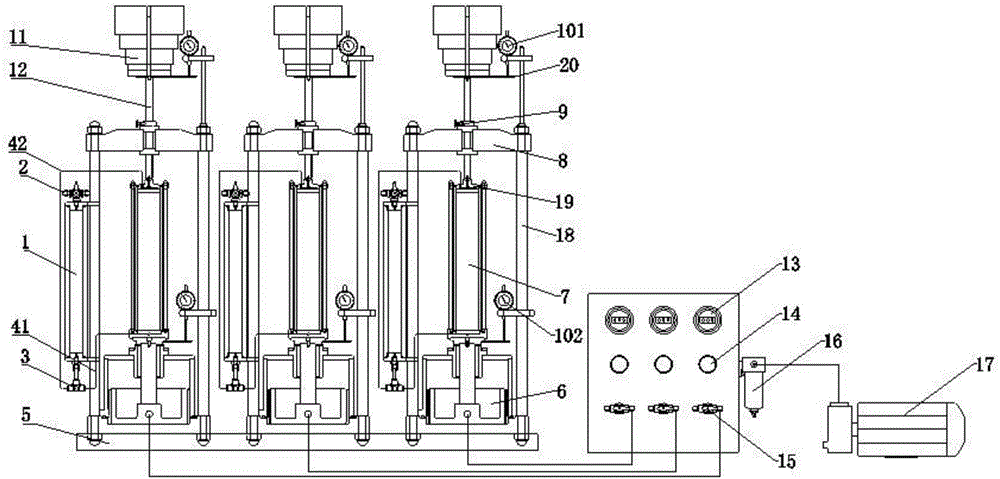

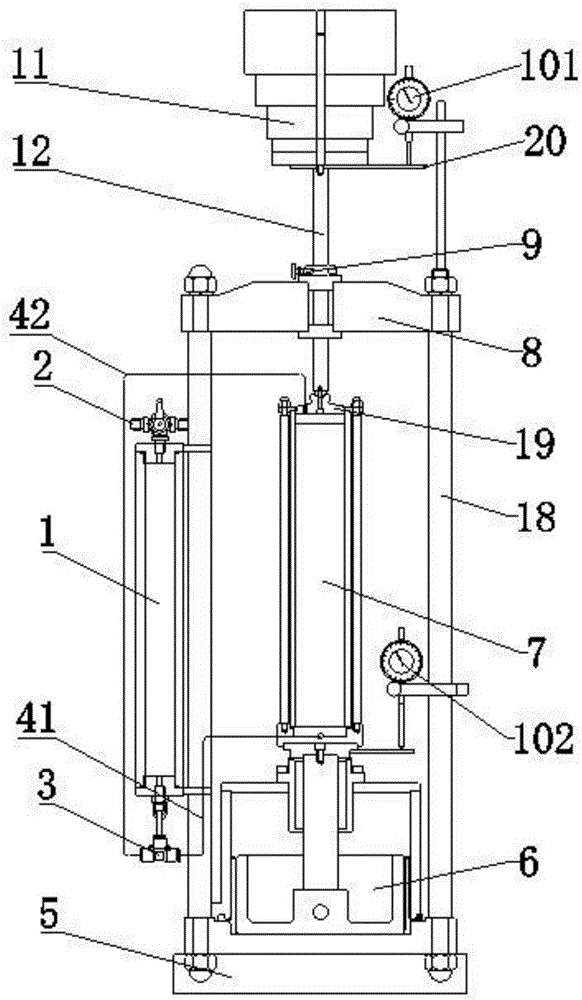

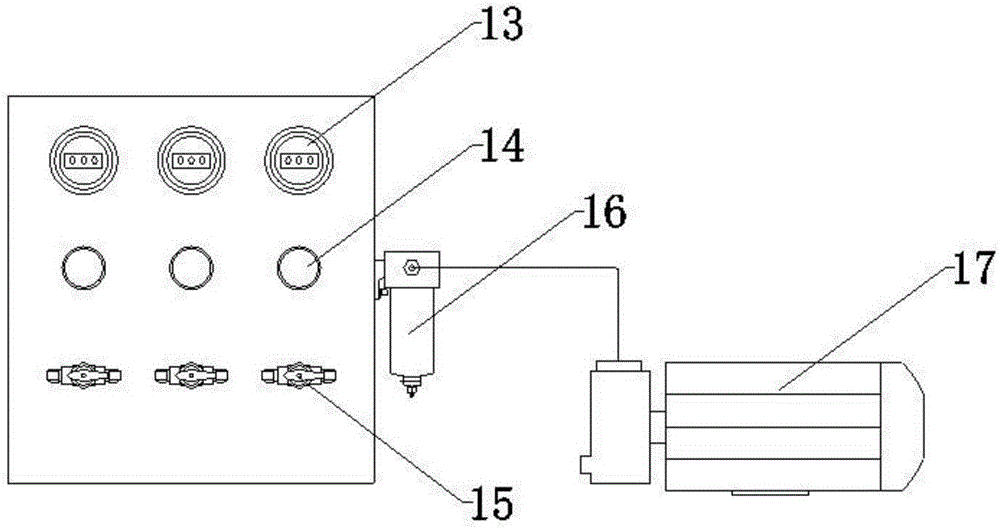

[0029] like figure 1 As shown, the present invention includes the air pressure pressurizing device part and the sample preparation cylinder part, and 3 remodeling soil sample sample cylinders 7 are fixed on the base 5, and the three sample preparation cylinders 7 can carry out sample preparation work independently or simultaneously; sample preparation The cylinder part includes a vertical sample cylinder 7, the top of the sample cylinder 7 is connected to the weight 11 through the pressure rod 12, the weight 11 is arranged on the tray 20 on the top of the pressure rod 12, and the bottom of the pressure rod 12 is provided with a The pressure plate 19 for applying pressure to the soil sample in the cylinder 7, the pressure plate 19 extends into the sample cylinder 7, the diameter of the pressure plate 19 is the same as the inner diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com