A kind of preparation method of polyimide foam and insulation pipe cover thereof

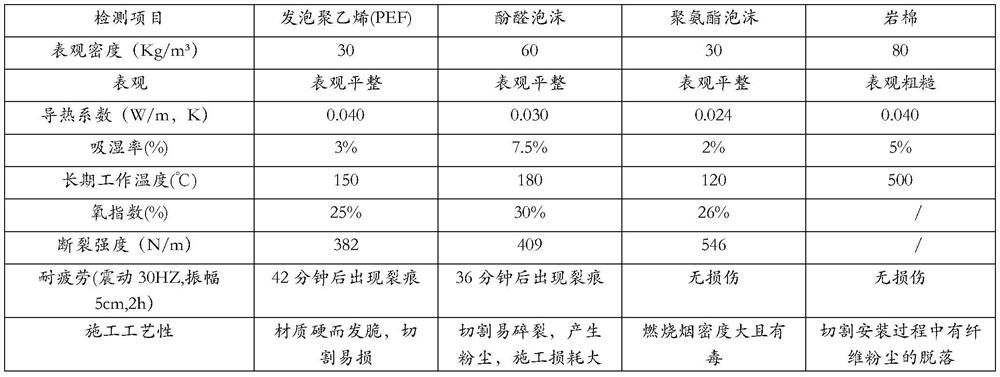

A technology of polyimide and foam, which is applied in the field of preparation of polyimide foam and its insulation pipe sleeve, can solve the problems of low-efficiency utilization of organic carbon resources, occupation of land, pollution of the environment, etc., and achieves excellent performance and effect , enhanced toughness, good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In parts by weight, add 100 parts of 3,3',4,4'-benzophenone tetra-acid dianhydride into 60 parts of polymethylene polyphenyl polyisocyanate and heat to 80°C, react for 0.4h, Let it pre-react 10% of the total mass, then add 50 parts of the blocking agent trihaloethanol to block the isocyanate, and then add 10 parts of the surfactant DC 200 to it, and disperse it by stirring at 600r / min and ultrasonic at 50KHZ Mix it thoroughly and evenly. Cool to normal temperature and become solid and slightly brittle, pulverize and pulverize with a 1000W ultrafine pulverizer for 0.2h to 1000 mesh as a binder for use;

[0033] The polyimide foam leftovers are crushed into foam particles with a particle size of 25mm by a foam pulverizer, and 20 parts of the adhesive obtained after the crushing in the preceding steps and 100 parts of the foam particles after the crushed leftovers are taken, and passed through a 2000W closed screw mixer Mix well; then fill it into a mold and place it in a...

Embodiment 2

[0035] Add 100 parts of 1,2,4,5-pyromellitic dianhydride to 100 parts of toluene diisocyanate and heat to 150°C, react for 3 hours, let it react 50% in advance, and then add 50 parts of blocking agent ortho Hydroquinone, the isocyanate is blocked, and then 15 parts of surfactant AK8803 is added to it, and it is fully mixed by 800r / min stirring and 60KHZ ultrasonic disperser. Cool to normal temperature and become solid and slightly brittle, pulverize with a 2000W ultrafine pulverizer for 3 hours to 2000 mesh as a binder for later use;

[0036]The polyimide foam scraps are pulverized into foam particles with a particle size of 5 mm by a foam pulverizer, and 200 parts of crushed adhesive and 100 parts of foam are taken and mixed thoroughly by a 160KW closed screw mixer; then filled into a mold , placed in an industrial microwave oven, the microwave power is 60KW, and the microwave foaming time is controlled to be 2h; after the temperature reaches 180°C, the isocyanate deblocks, r...

Embodiment 3

[0038] Add 100 parts of 3,3',4,4'-diphenyl ether tetra-acid dianhydride to 70 parts of isophorone diisocyanate and heat to 60°C, react for 0.3h, let it react 5% in advance, and then add 35 parts of capping agent ethanol is used to block isocyanate, and then 5 parts of surfactant AK8805 are added to it, and it is fully mixed evenly by stirring at 500r / min and ultrasonic disperser at 150KHZ. Cool to normal temperature and become solid and slightly brittle, pulverize with a 1500W ultrafine pulverizer for 0.2h to 1500 mesh as a binder for use;

[0039] The polyimide foam scraps are pulverized into foam particles with a particle size of 50 mm by a foam pulverizer, and 10 parts of pulverized adhesive and 100 parts of foam are fully mixed by a closed screw mixer; then filled into a mould, Placed in an industrial microwave oven, the microwave power is 60KW, and the microwave foaming time is controlled to be 2 hours; after the temperature reaches 190°C, the isocyanate deblocks, reacts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com