A preparation method of carbon fiber/toughened epoxy resin prepreg for vacuum bag forming process

A technology for toughening epoxy resin and epoxy resin, applied in the field of carbon fiber/toughening epoxy resin prepreg preparation, can solve the requirements of resin raw materials and resin preparation process, affect resin fluidity and room temperature storage, hinder Resin flow and fiber impregnation, etc., to achieve the effects of precise control of resin content and fiber surface density, easy promotion, and strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] As mentioned above, the epoxy resin system can be prepared by the preparation method of the resin matrix well known to those skilled in the art, preferably by mixing and preparing with a planetary mixer, and the preparation steps are as follows:

[0042] Step 1: Take 60-100 parts of epoxy resin and its composition by mass ratio, 5-25 parts of toughening agent, and 30-55 parts of amine epoxy resin curing agent; The toughness, fluidity and curing characteristics of the resin shall meet the requirements.

[0043] Step 2: According to the order of epoxy resin and its composition, toughening agent and curing agent, add the raw materials weighed in step 1 into the barrel and stir at a certain temperature for a period of time. The preferred stirring temperature in this step is 70-120° C., and the preferred stirring time is 10-40 min. The specific stirring temperature and stirring time shall be subject to the incomplete dissolution of the thermoplastic resin particles and curi...

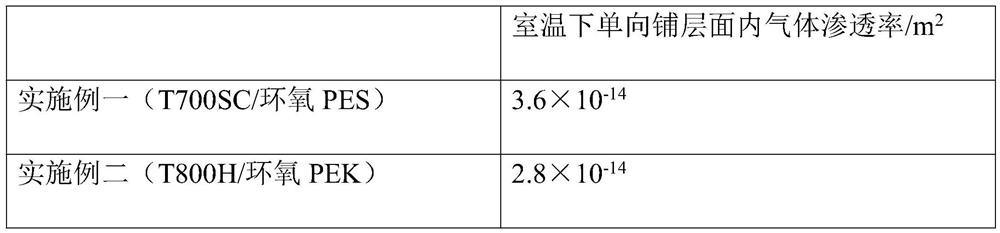

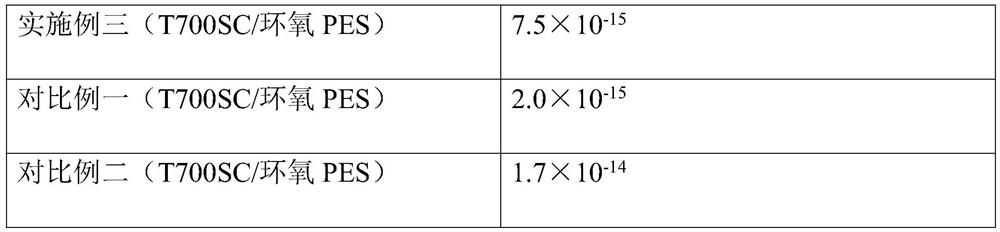

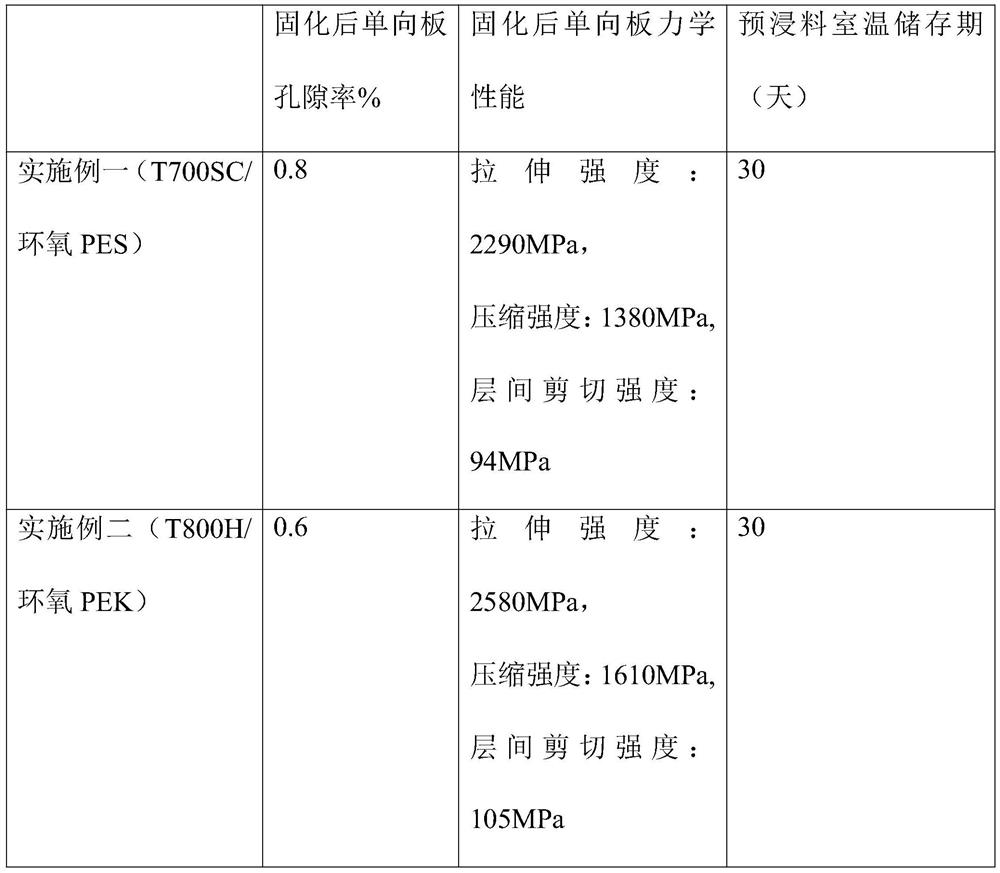

Embodiment 1

[0052] Use T700SC carbon fiber tow to prepare fiber surface density of 150g / m 2 OoA prepregs. According to 80 parts by mass of AG80 resin, 20 parts by mass of E44 resin, 25 parts by mass of polyethersulfone (PES, D90 is 50 μm), 47 parts by mass of 4,4'-DDS (D90 is 30 μm), 0.5 parts by mass of The ratio of boron trifluoride monoethylamine is used to prepare epoxy resin.

[0053] Resin mixing steps: Add AG80 resin and E44 resin to the cylinder of planetary mixer, mix for about 10 minutes at 100°C; add PES, mix for about 30 minutes at 100°C; add 4,4'-DDS, mix for about 30 minutes at 100°C; add trifluoro Boron monoethylamine, mixed at 100°C for about 5 minutes.

[0054] Prepreg preparation steps: the resin mixture obtained in the above steps is coated on the release paper at 70°C, and the thickness of the resin film is controlled so that the surface density of the resin film is 40g / m 2 . The carbon fiber tow is compounded with the resin film on both sides at 65 °C and the pres...

Embodiment 2

[0056] Use T800H carbon fiber tow to prepare fiber surface density of 125g / m 2 OoA prepregs. According to 80 parts by mass of AFG90 resin, 10 parts by mass of E51 resin, 15 parts by mass of polyether ketone (PEK, D90 is 60 μm), 53 parts by mass of 4,4'-DDS (D90 is 25 μm), 0.5 parts by mass of The ratio of boron trifluoride monoethylamine is used to prepare epoxy resin.

[0057] Resin mixing steps: Add AFG90 resin and E51 resin to the cylinder of planetary mixer, mix for about 10 minutes at 90°C; add PEK, mix for about 30 minutes at 90°C; add 4,4'-DDS, mix for about 30 minutes at 90°C; add trifluoro Boron monoethylamine, mixed at 90°C for about 5 minutes.

[0058] Prepreg preparation steps: the resin mixture obtained in the above steps is coated on the release paper at 60°C, and the thickness of the resin film is controlled so that the surface density of the resin film is 34g / m 2 . The carbon fiber tow and the resin film on both sides are compounded under the conditions of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com