Aqueous solar energy heat-absorbing coating

A solar energy absorption and coating technology, applied in the direction of radiation-absorbing coatings and coatings, can solve the problems of high cost and complex preparation process, and achieve the effects of low equipment requirements, simple preparation process and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

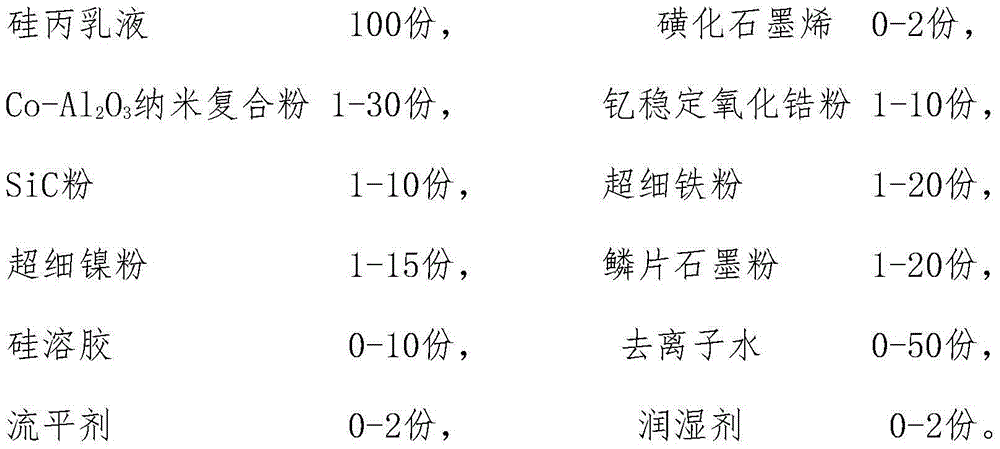

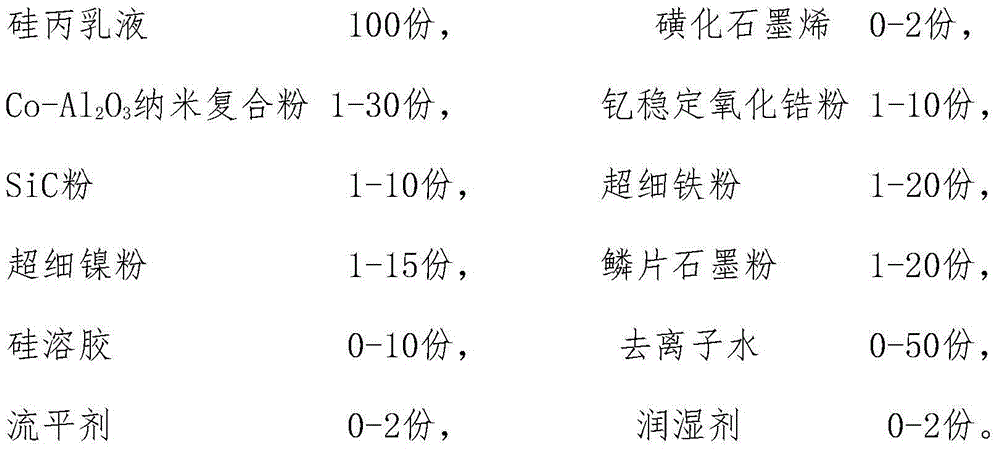

Method used

Image

Examples

Embodiment 1

[0022] A water-based solar heat-absorbing coating, in parts by weight:

[0023] 100 parts of silicon acrylic emulsion, 1 part of sulfonated graphene, Co-Al 2 o 3 12 parts of nanocomposite powder, 6 parts of yttrium stabilized zirconia powder, 6 parts of SiC powder, 10 parts of ultrafine iron powder, 4 parts of ultrafine nickel powder, 15 parts of flake graphite powder, 3 parts of silica sol, 4 parts of deionized water, 0.5 parts of leveling agent and 0.5 parts of wetting agent. At room temperature, grind the solid powder and liquid raw materials according to the weight ratio on the sander for 30 minutes to mix the materials evenly, and finally filter the prepared solution with a 1000-mesh filter, and put the filtered solution in a paint container for sealed storage , to obtain the water-based solar heat-absorbing coating.

[0024] The water-based solar heat-absorbing coating is evenly coated on the surface of the zinc steel plate, and the black water-based solar heat-absorb...

Embodiment 2

[0027] A water-based solar heat-absorbing coating, in parts by weight:

[0028] 100 parts of silicon acrylic emulsion, 0.5 parts of sulfonated graphene, Co-Al 2 o 318 parts of nanocomposite powder, 3 parts of yttrium stabilized zirconia powder, 4 parts of SiC powder, 5 parts of ultrafine iron powder, 8 parts of ultrafine nickel powder, 12 parts of flake graphite powder, 3 parts of silica sol, 4 parts of deionized water, 0.5 parts of leveling agent and 0.5 parts of wetting agent. At room temperature, the solid powder and liquid raw materials according to the weight ratio are ground on a sander for 40 minutes to mix the materials evenly, and finally the prepared solution is filtered with a 1000-mesh filter, and the filtered solution is sealed and stored in a paint container. , to obtain the water-based solar heat-absorbing coating.

[0029] The water-based solar heat-absorbing coating is evenly coated on the surface of the zinc steel plate, and after being completely cured at...

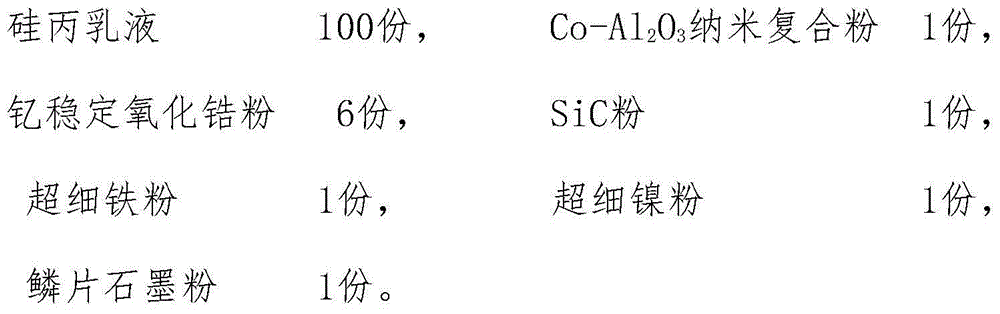

Embodiment 3

[0031] A water-based solar heat-absorbing coating, in parts by weight:

[0032] 100 parts of silicon acrylic emulsion, 2 parts of sulfonated graphene, Co-Al 2 o 3 30 parts of nanocomposite powder, 9 parts of yttrium stabilized zirconia powder, 8 parts of SiC powder, 15 parts of ultrafine iron powder, 12 parts of ultrafine nickel powder, 18 parts of flake graphite powder, 10 parts of silica sol, 4 parts of deionized water, 0.5 parts of leveling agent and 0.5 parts of wetting agent. At room temperature, the solid powder and liquid raw materials according to the weight ratio are ground on a sander for 60 minutes to mix the materials evenly, and finally the prepared solution is filtered with a 1000-mesh filter, and the filtered solution is sealed and stored in a paint container. , to obtain the water-based solar heat-absorbing coating.

[0033] The water-based solar heat-absorbing coating is uniformly coated on the surface of the zinc steel plate, and after being completely cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com