A kind of zirconia ceramic and its preparation method

A technology of zirconia ceramics and neodymium oxide, which is applied to the field of colored zirconia ceramics and their preparation, can solve the problem that the zirconia ceramics cannot show purple, and achieve the effects of stable color rendering, pure and beautiful color, and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

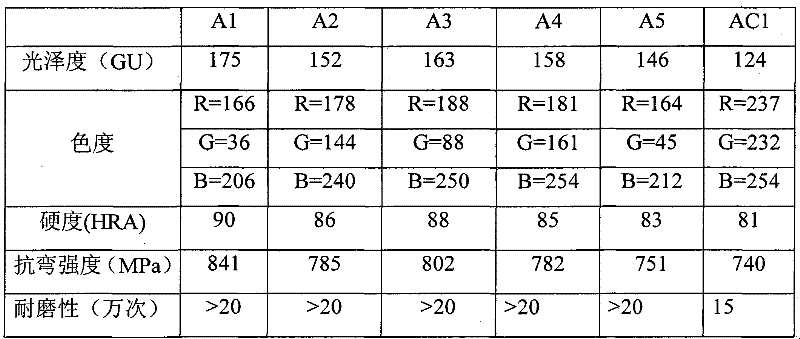

Examples

preparation example Construction

[0025] The preparation method of purple zirconia ceramics of the present invention, it comprises the steps:

[0026] (1) Neodymium oxide pretreatment: adding neodymium oxide particles into diethanolamine solution for soaking, and then separating the solid and liquid;

[0027] (2) Compression molding sintering: the base material, sintering aids, additives, and neodymium oxide particles pretreated in step (1) are ball milled and mixed, then molded and sintered at high temperature.

[0028] The average particle diameter of the neodymium oxide particles of the present invention is preferably 0.1 to 20 μm, more preferably 1 to 10 μm.

[0029] Wherein, the present invention does not have too many restrictions on the amount of the diethanolamine solution, as long as it can completely submerge the neodymium oxide. In the present invention, the dosage of the diethanolamine solution per gram of neodymium oxide is preferably 10-40 mL.

[0030] Preferably, the concentration of the dieth...

Embodiment 1

[0043] Substrate: 88 g of semi-stabilized yttria-stabilized zirconia, wherein the mole fraction of yttria is 3%.

[0044] Sintering aids: 0.6g magnesium oxide, 0.8g silicon oxide, 0.6g aluminum oxide

[0045] Neodymium oxide: 8 g of neodymium oxide with an average particle size of 5 μm

[0046] Additives: 0.4g zinc oxide, 0.8g barium carbonate, 0.8g calcium fluoride

[0047] (1) Pretreatment: First, add neodymium oxide particles into 240ml of 3mol / L diethanolamine solution, and stir for 1 hour at 200rad / min. Then the neodymium oxide particles were filtered out from the diethanolamine solution and dried at 100°C for 0.5h.

[0048] (2) Molding sintering: Add the matrix, sintering aids, neodymium oxide obtained in step (1) and additives into 200 mL of absolute ethanol, and then ball mill and mix for 6 hours. After taking it out, place it in an oven at 100°C for 6 hours. The obtained powder was crushed with a porcelain mortar and passed through a 200-mesh sieve. Use a four-co...

Embodiment 2

[0050] Substrate: 94 g of semi-stabilized yttria-stabilized zirconia, wherein the mole fraction of yttria is 3.5%.

[0051] Sintering aids: 0.5g magnesium oxide, 0.5g calcium oxide

[0052] Neodymium oxide: 3 g of neodymium oxide with an average particle size of 1 μm

[0053] Additives: 0.4g zinc oxide, 0.8g barium carbonate, 0.8g calcium fluoride

[0054](1) Pretreatment: First, add neodymium oxide particles into 90ml of 3mol / L diethanolamine solution, and stir for 1h at a speed of 200rad / min. Then the neodymium oxide particles were filtered out from the diethanolamine solution and dried at 100°C for 0.5h.

[0055] (2) Molding and sintering: Add the matrix, sintering aids, neodymium oxide obtained in step (1) and additives into 200 mL of absolute ethanol, and then ball mill and mix for 6 hours. After taking it out, place it in an oven at 100°C for 6 hours. The obtained powder was crushed with a porcelain mortar and passed through a 200-mesh sieve. Use a four-column press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com