Dielectric energy-storing anti-ferroelectric ceramic material and preparation method thereof

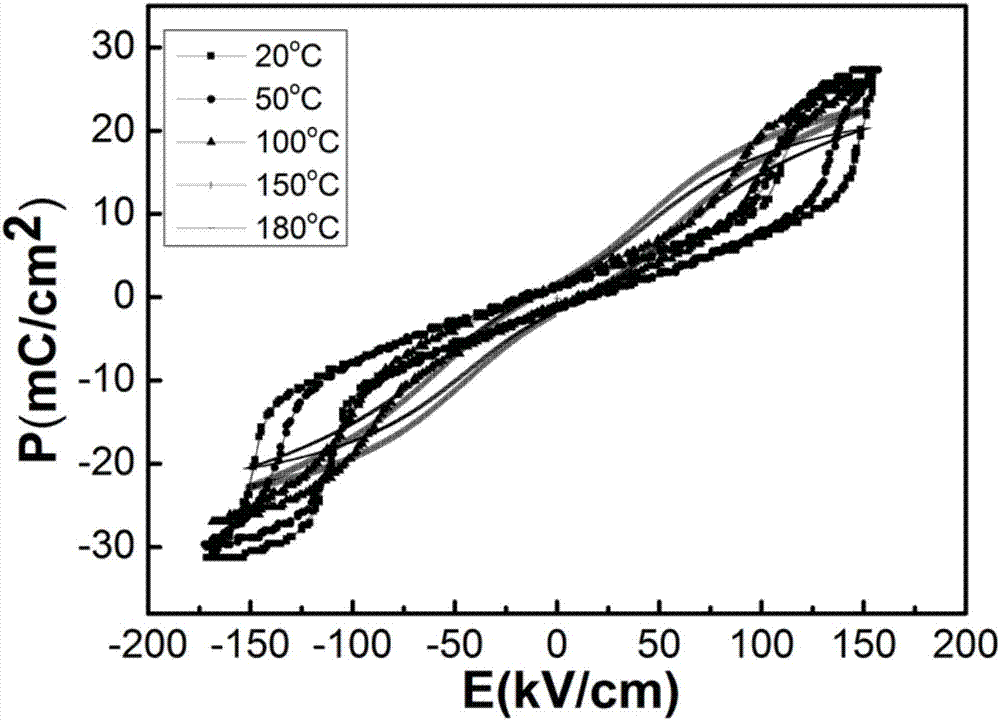

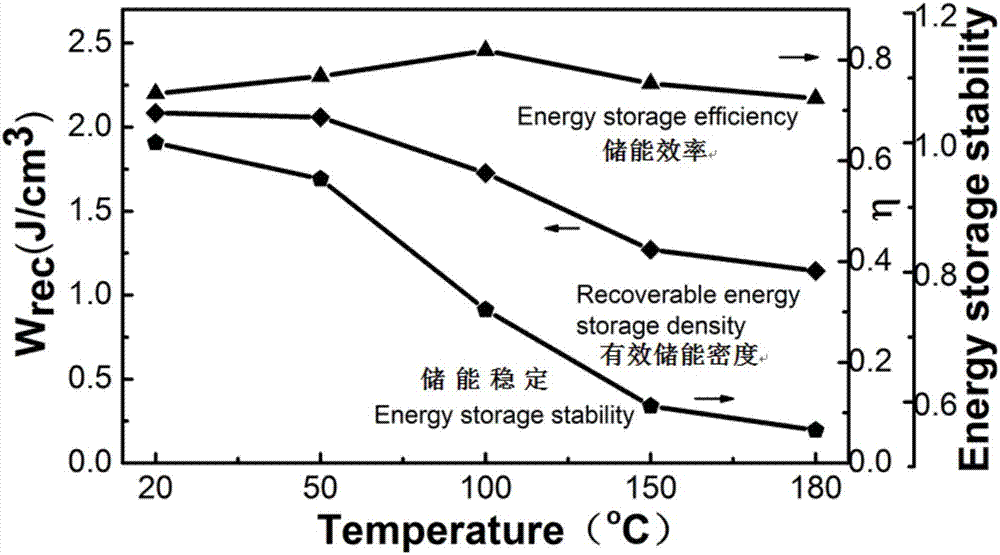

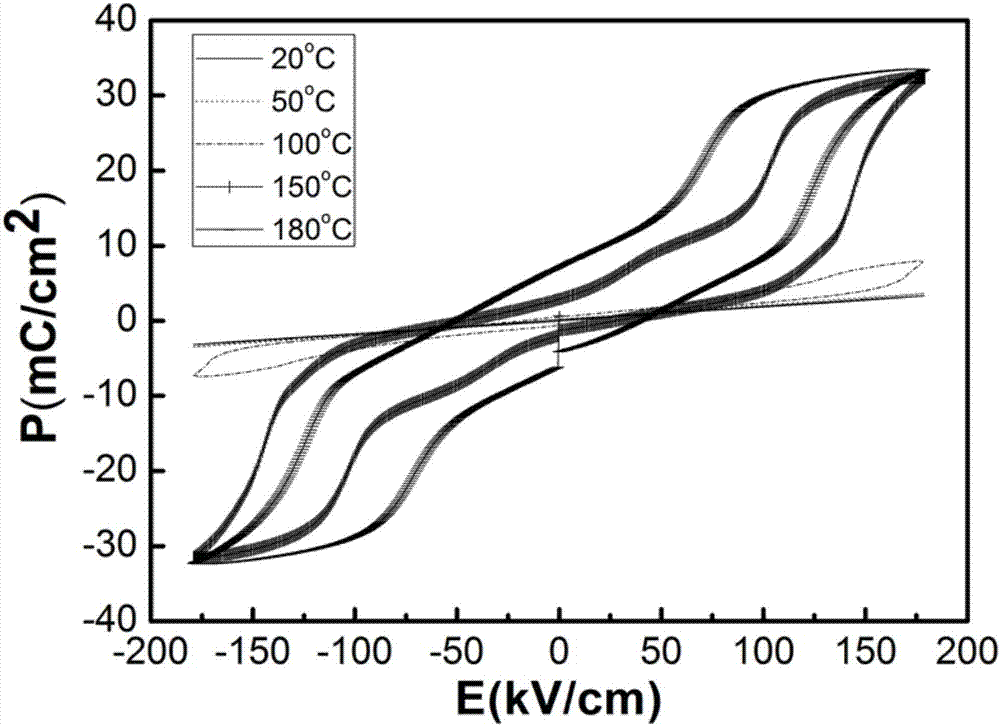

A ceramic material and dielectric energy storage technology, applied in the field of dielectric energy storage antiferroelectric ceramic materials and their preparation, can solve problems such as poor temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a dielectric energy storage antiferroelectric ceramic material, comprising:

[0033] (1) mixing the antiferroelectric ceramic powder material with a negative temperature coefficient of energy storage density and the antiferroelectric ceramic powder material with a positive temperature coefficient of energy storage density according to the mass ratio (30-80):(20-70) to obtain a mixed powder;

[0034] (2) Add polyvinyl alcohol solution to the mixed powder, and then sinter to obtain the dielectric energy storage antiferroelectric ceramic material.

Embodiment 1

[0036] (1) Preparation of antiferroelectric ceramic powder material with negative temperature coefficient of energy storage density:

[0037]Weigh the raw materials PbO (99.9%), BaCO 3 (99.8%), La 2 o 3 (99.9%), ZrO 2 (99.5%), SnO 2 (99.6%) and TiO 2 (99.6%), adopt wet ball milling method, according to raw material: alcohol=1: 0.6 mass ratio ball milling 6 hours, rise to 850 ℃ with 5 ℃ per minute after drying, in air insulation 3 hours. The obtained powder is ball milled, dried, and sieved, pre-pressed with a pressure of 20 MPa, and the pre-pressed powder is subjected to secondary sieving to obtain a pre-fired powder of an antiferroelectric ceramic material with a negative temperature coefficient of energy storage density .

[0038] (2) Preparation of antiferroelectric ceramic powder material with positive temperature coefficient of energy storage density:

[0039] Weigh raw materials PbO (99.9%), La 2 o 3 (99.9%), ZrO 2 (99.5%), SnO 2 (99.6%) and TiO 2 (99.6%), ad...

Embodiment 2

[0043] (1) make the calcined powder body of energy storage density negative temperature coefficient antiferroelectric ceramic material with (1) identical method in embodiment 1;

[0044] (2) make the calcined powder body of energy storage density positive temperature coefficient antiferroelectric ceramic material with (2) identical method in embodiment 1;

[0045] (3) Mix the antiferroelectric ceramic material with negative temperature coefficient of energy storage density and antiferroelectric ceramic material with positive temperature coefficient of energy storage density according to the mass ratio of 50:50, ball mill and mix for 4 hours, after drying and pulverizing, add concentration 5% PVA solution, the solution accounted for 8% by mass of the powder, after granulation and dry pressing, sintering at 1230°C for 3 hours, and annealing at 1000°C for 1 hour to make a dielectric storage Antiferroelectric ceramic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com