Three-phase composite high-dielectric-property material, manufacturing method and processing method

A high-dielectric, high-performance technology, used in the field of processing embedded capacitors, can solve the problems of large conductivity loss, loss of practical value of conductor/polymer composite materials, etc., and achieve the effects of low loss, excellent dispersion, and excellent dielectric properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

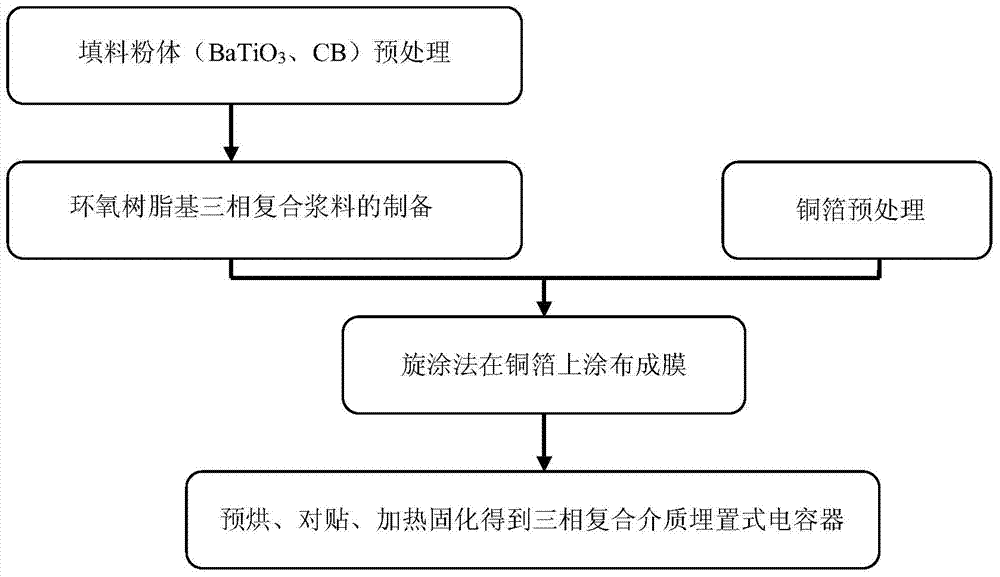

[0053] The preparation method of the three-phase composite high dielectric performance material of the present invention uses carbon black, barium titanate and epoxy resin as the main ingredients, and the overall technical route (preparation method process) is as follows figure 1 As shown, the preparation is carried out according to the following steps:

[0054] 1) Barium titanate preprocessing;

[0055] 1.1) Add powdered barium titanate into absolute ethanol, mix evenly to obtain a suspension;

[0056] 1.2) Then take the silane coupling agent accounting for 1-2 weight% of the barium titanate powder, add it to dilute with absolute ethanol whose mass is 18-25 times the mass of the silane coupling agent, and obtain an activated diluent;

[0057] 1.3) Add the activated diluent dropwise into the aforementioned suspension at a rate of 1-3 drops per second, stir evenly while adding, and then perform centrifugation;

[0058] 1.4) Dried after centrifugation to obtain surface-activat...

Embodiment 1

[0083] Embodiment one: prepare according to the following steps:

[0084] 1) Barium titanate preprocessing;

[0085] 1.1) Add powdered barium titanate into absolute ethanol, mix evenly to obtain a suspension;

[0086] 1.2) Take the silane coupling agent accounting for 1 weight% of the mass of the barium titanate powder, add it to anhydrous ethanol whose mass is 18 times the mass of the silane coupling agent, and dilute to obtain an activated diluent;

[0087] 1.3) Add the activated diluent dropwise into the aforementioned suspension at a rate of 1 drop per second, stir evenly while adding dropwise, and then perform centrifugation;

[0088] 1.4) Dried after centrifugation to obtain surface-activated barium titanate;

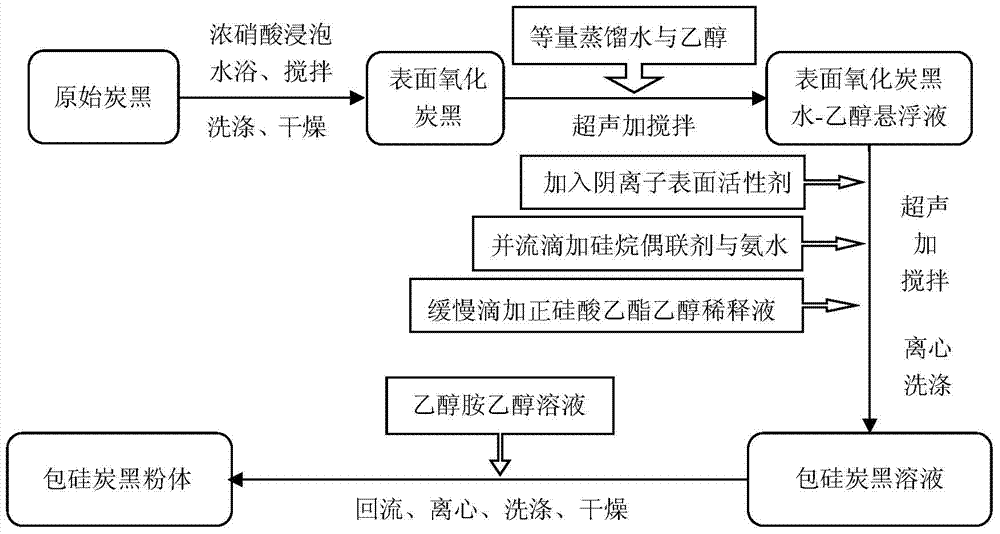

[0089] 2) carbon black preprocessing; such as figure 2 as shown,

[0090] 2.1) Add carbon black to 30 times the mass of nitric acid with a mass fraction of 34%, mix evenly, place in a water bath at 75°C, and stir for 1 hour; obtain an acidic carbon black susp...

Embodiment 2

[0101] Embodiment two: prepare according to the following steps:

[0102] 1) Barium titanate preprocessing;

[0103] 1.1) Add powdered barium titanate into absolute ethanol, mix evenly to obtain a suspension;

[0104] 1.2) Take the silane coupling agent accounting for 2 weight% of the mass of the barium titanate powder and add it to dilute with absolute ethanol 25 times the mass of the silane coupling agent to obtain an activated diluent;

[0105] 1.3) Add the activated diluent dropwise into the aforementioned suspension at a rate of 3 drops per second, stir evenly while adding dropwise, and then perform centrifugation;

[0106] 1.4) Dried after centrifugation to obtain surface-activated barium titanate;

[0107] 2) carbon black preprocessing; such as figure 2 as shown,

[0108] 2.1) Add carbon black to 40 times the mass of nitric acid with a mass fraction of 34%, mix evenly, place in a water bath at 85°C, and stir for 2 hours; obtain an acidic carbon black suspension;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com