(K0.5Na0.5)NbO3-Sr(Sc0.5Nb0.5)O3 leadless transparent ferroelectric ceramic material and preparation method thereof

A technology of ferroelectric ceramics, nbo3-sr, applied in the field of preparation of functional ceramics, can solve the problems of less research and achieve the effects of low preparation cost, simple preparation process and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

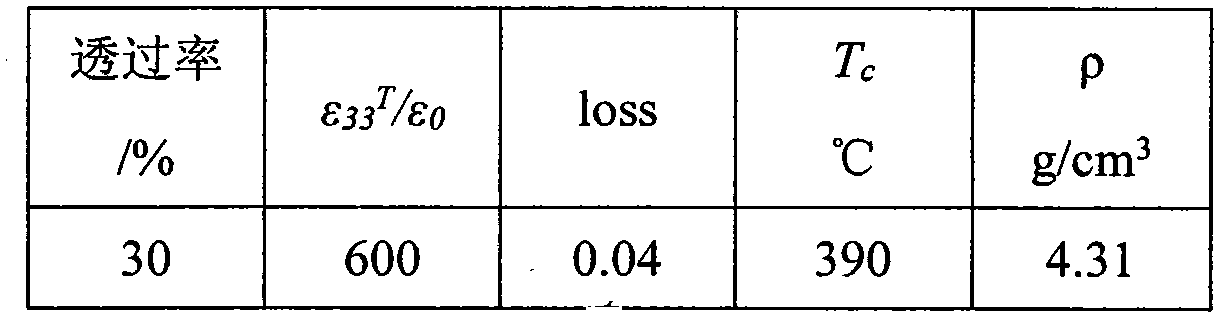

Embodiment 1

[0019] The raw material of present embodiment comprises anhydrous potassium carbonate, anhydrous sodium carbonate, anhydrous strontium carbonate, niobium pentoxide and scandium trioxide, and its stoichiometric ratio is 0.98 (K 0.5 Na 0.5 )NbO 3 -0.02Sr(Sc 0.5 Nb 0.5 )O 3 .

[0020] The preparation process of this embodiment is:

[0021] (1) Place analytically pure anhydrous potassium carbonate, anhydrous sodium carbonate, anhydrous strontium carbonate, niobium pentoxide and scandium trioxide at 150°C for 10 hours, and the stoichiometric ratio is 0.98 (K 0.5 Na 0.5 )NbO 3 -0.02Sr(Sc 0.5 Nb 0.5 )O 3 . ingredients.

[0022] (2) Raw materials are prepared with ZrO in absolute ethanol 2 The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. The obtained powder was kept at 950°C in air for 5 hours, the calcined powder was subjected to planetary ball milling for 12 hours and then calcined again in 900°C air for 2 hours, and the p...

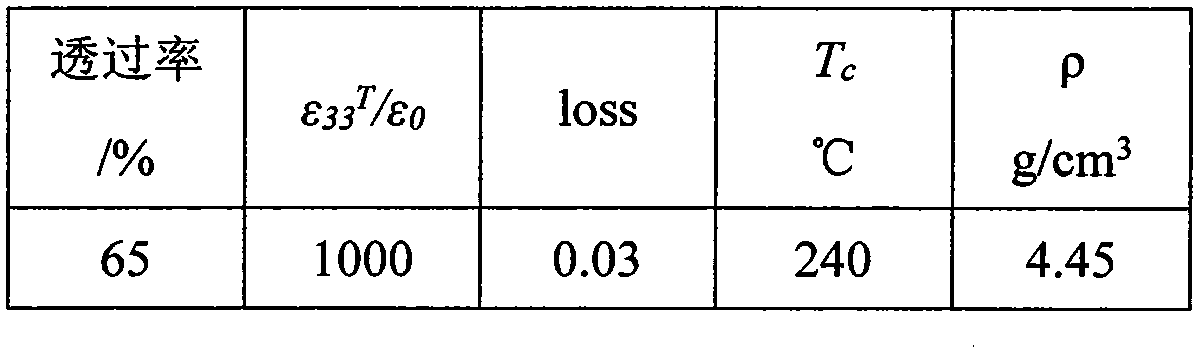

Embodiment 2

[0032] The raw material of embodiment comprises anhydrous potassium carbonate, anhydrous sodium carbonate, anhydrous strontium carbonate, niobium pentoxide and scandium trioxide, and its stoichiometric ratio is 0.94 (K 0.5 Na 0.5 )NbO 3 -0.06Sr(Sc 0.5 Nb 0.5 )O 3 .

[0033] The preparation process of this embodiment is:

[0034] (1) Place analytically pure anhydrous potassium carbonate, anhydrous sodium carbonate, anhydrous strontium carbonate, niobium pentoxide and scandium trioxide at 150°C for 10 hours, and the stoichiometric ratio is 0.94 (K 0.5 Na 0.5 )NbO 3 -0.06Sr(Sc 0.5 Nb 0.5 )O 3 . ingredients.

[0035] (2) Raw materials are prepared with ZrO in absolute ethanol 2 The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. The obtained powder was kept at 950°C in air for 5 hours, the calcined powder was subjected to planetary ball milling for 12 hours and then calcined again in 900°C air for 2 hours, and the powder wi...

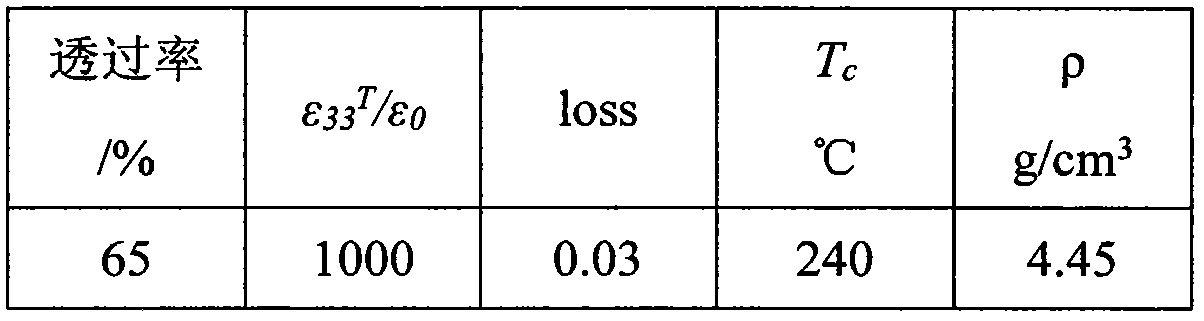

Embodiment 3

[0045] The raw material of embodiment comprises anhydrous potassium carbonate, anhydrous sodium carbonate, anhydrous strontium carbonate, niobium pentoxide and scandium trioxide, and its stoichiometric ratio is 0.9(K 0.5 Na 0.5 )NbO 3 -0.1Sr(Sc 0.5 Nb 0.5 )O 3 .

[0046] The preparation process of this embodiment is:

[0047] (1) Place analytically pure anhydrous potassium carbonate, anhydrous sodium carbonate, anhydrous strontium carbonate, niobium pentoxide and scandium trioxide at 150°C for 10 hours, and the stoichiometric ratio is 0.9(K 0.5 Na 0.5 )NbO 3 -0.1Sr(Sc 0.5 Nb 0.5 )O 3 . ingredients.

[0048] (2) Raw materials are prepared with ZrO in absolute ethanol 2 The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. The obtained powder was kept at 950°C in air for 5 hours, the calcined powder was subjected to planetary ball milling for 12 hours and then calcined again in 900°C air for 2 hours, and the powder with per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com