Ferro-voltage ceramic component with low sintering temperature character, production and uses thereof

A low sintering temperature, piezoelectric ceramic technology, applied in the field of material science, can solve the problems of small chemical uniformity and grain size, reduce the chemical ratio of PZT, deterioration of driver performance, etc., to reduce industrial energy consumption and cost, reduce The effect of volatilization and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

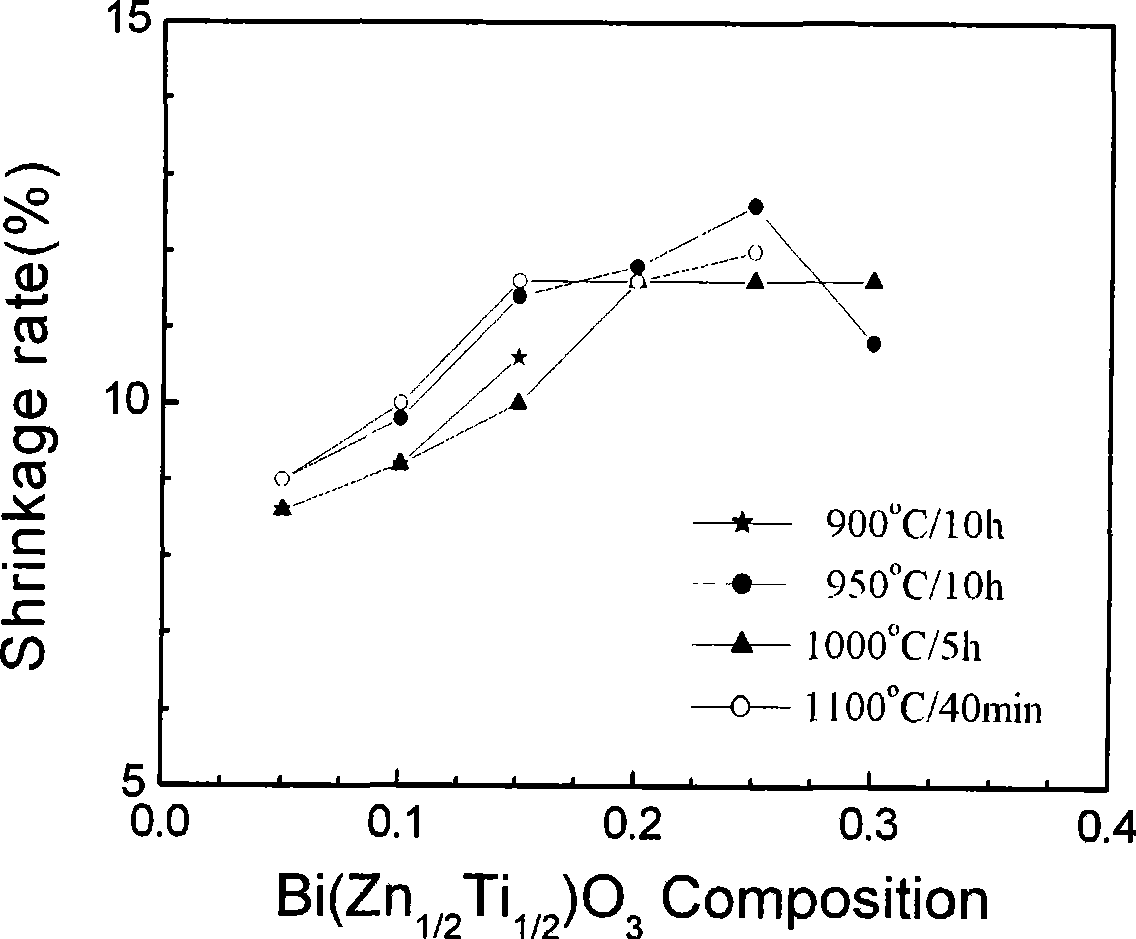

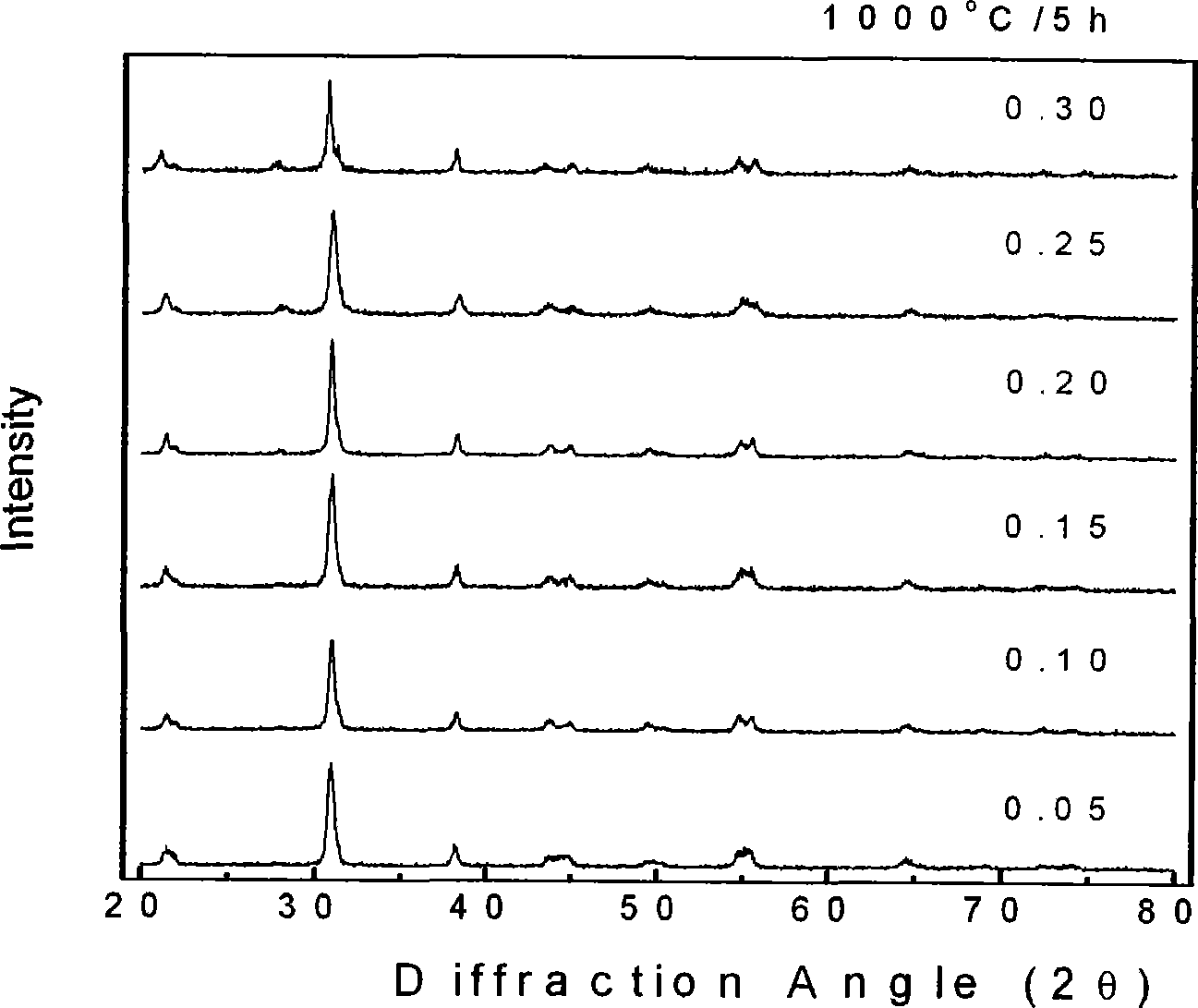

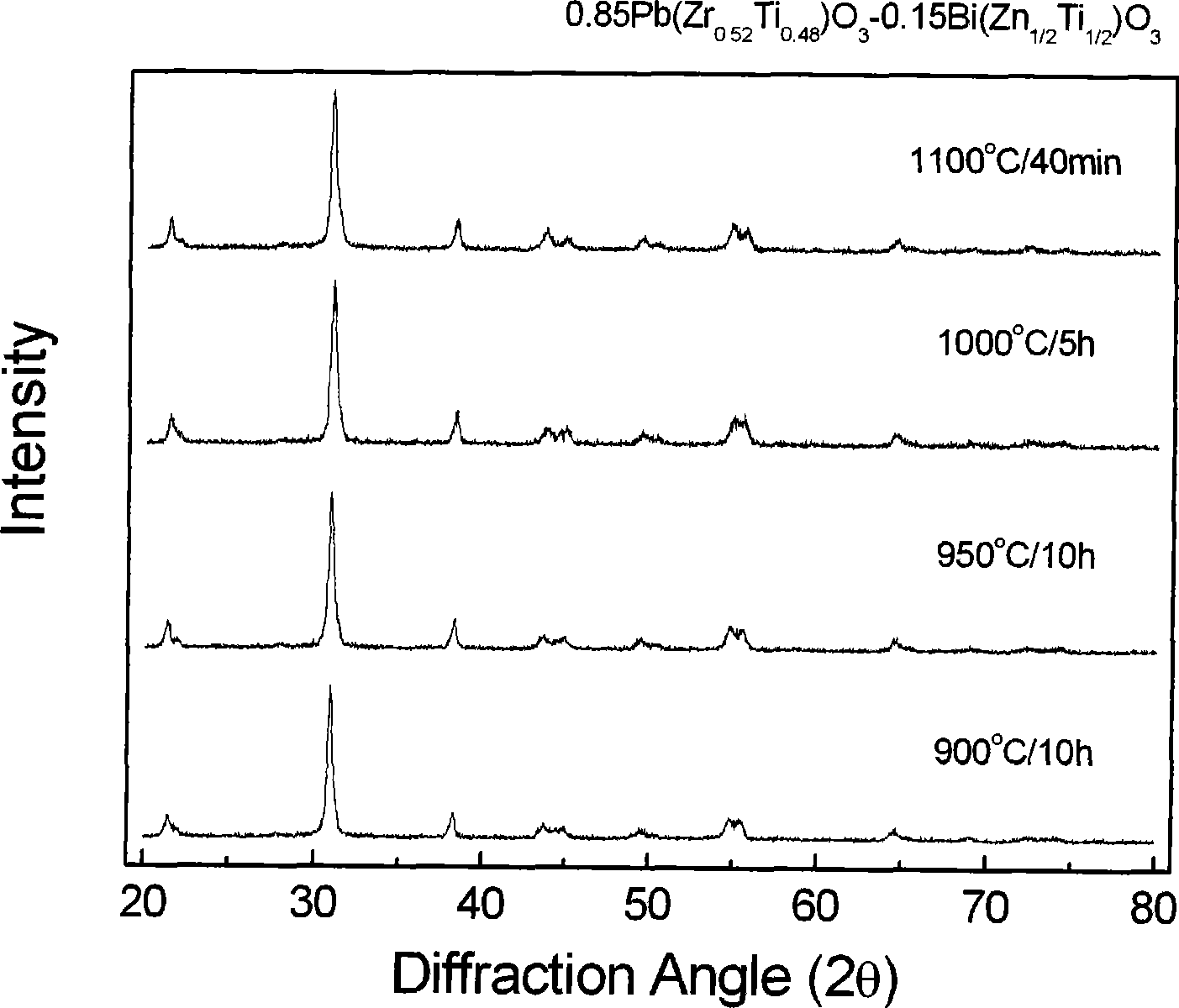

[0046] 1. (1-x)Pb(Zr 0.52 Ti 0.48 )O 3 -xBi(Zn 1 / 2 Ti 1 / 2 )O 3 Preparation of Ferroelectric Piezoelectric Ceramics: Bi 2 o 3 , PbO, ZnO, ZrO 2 and TiO 2 Weigh the oxide powder according to the stoichiometric ratio, add absolute ethanol and grind it in an agate mortar for 2 hours, pre-fire at 800°C for 5 hours; add absolute ethanol and grind it in an agate mortar for 2 hours, and then granulate; uniaxial stress molding, forming The pressure is 250MPa, and the diameter of the green body is 10mm; the green sheet is sintered at 900°C-1100°C for 40 minutes-10 hours. Sintered ceramic sheet shrinkage see figure 1 , For x=0.10-0.25 samples, the sintering shrinkage at 950°C is greater than 10%. X-ray diffraction measurement x=0.10-0.20 The sample is a single-phase perovskite structure, the test results are shown in figure 2 with image 3 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com