La-doped lead zirconate stannate titanate anti-ferroelectric ceramics with high energy storage efficiency and preparation method thereof

A technology of energy storage efficiency and antiferroelectricity, which is applied in the field of functional ceramics to achieve the effects of small electric hysteresis, long energy storage density, and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of PLZST antiferroelectric ceramic material of the present invention, comprises the steps:

[0038] (a) with Pb 3 o 4 , ZrO 2 、TiO 2 , SnO 2 , La 2 o 3 The powder is used as raw material, according to (Pb 0.97 La 0.02 )(Zr 0.58 sn 0.42-x Ti x )O 3 The stoichiometric ratio of the corresponding elements is prepared, and mixed by wet ball milling; after drying, it is compacted, and after pre-fired, a ceramic block is obtained;

[0039] In the mixing of wet ball milling method described in step (a), according to the mass ratio of raw material: ball: water = 1: (1.4 ~ 1.8): (0.7 ~ 1.0), mix for 5 ~ 7 hours, wherein the ball milling medium is steel ball Or agate ball, the water is deionized water;

[0040] The sintering conditions are as follows: the heating rate is lower than 2°C / min to 820-880°C, and the temperature is kept for 1-3 hours;

[0041] (b) finely grinding the ceramic blocks obtained in step (a) by wet ball milling, adding a b...

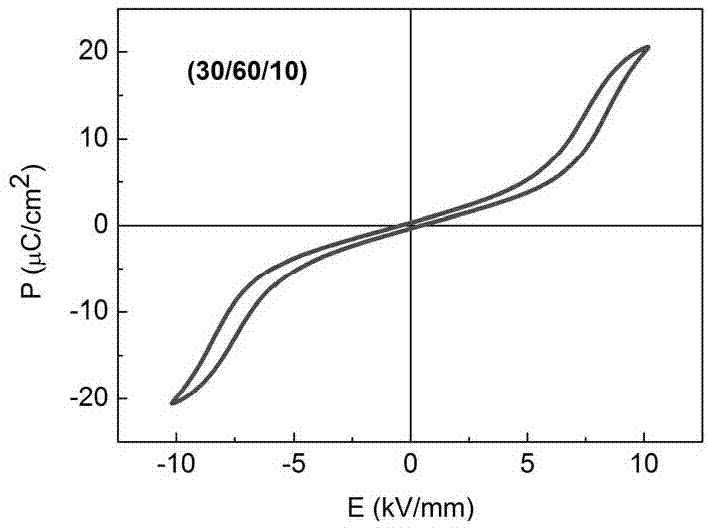

Embodiment 1

[0054] The antiferroelectric ceramic material is composed of: Pb 0.97 La 0.02 (Zr 0.3 sn 0.6 Ti 0.1 )O 3

[0055] (1) Calculate the composition Pb in the powder raw material according to the composition of the above chemical formula 3 o 4 , La 2 o 3 , ZrO 2 、TiO 2 and SnO 2 The mass is prepared according to the composition ratio, mixed by wet ball milling, and mixed for 7 hours according to the mass ratio of raw materials: ball: water = 1:1.6:0.9, so that the components are mixed evenly. After drying, pass through a 40-mesh sieve, briquette in an air atmosphere, raise the temperature to 850°C at a rate of 2°C / min, and keep it warm for 2 hours to synthesize Pb 0.97 La 0.02 (Zr 0.58 sn 0.33 Ti 0.09 )O 3 ceramic blocks;

[0056] (2) smash the ceramic block obtained in step (1), pass through a 30-mesh sieve, and finely grind for 24 hours by wet ball milling, dry the ceramic powder after fine grinding, and then add 7wt.% of the powder weight PVA binder, granulate...

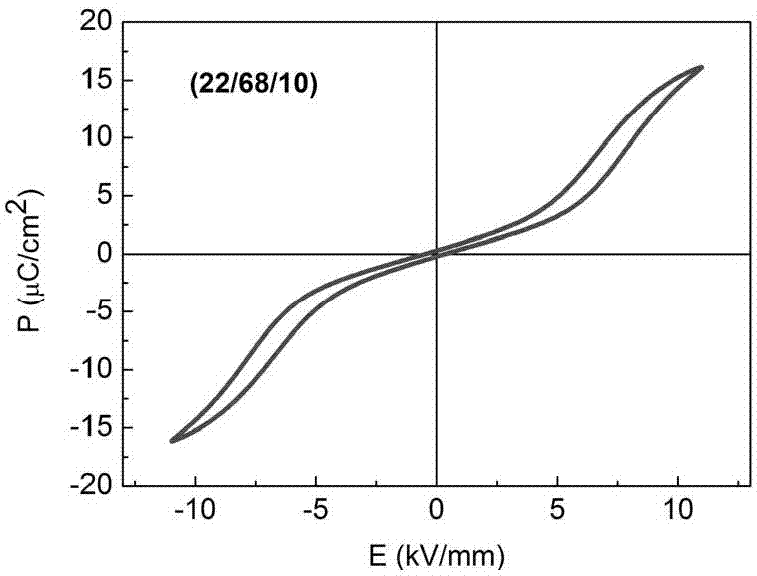

Embodiment 2

[0061] The material composition is: Pb 0.97 La 0.02 (Zr 0.22 sn 0.68 Ti 0.1 )O 3

[0062] Repeat the preparation method of Example 1 according to the above formula to prepare ceramic elements;

[0063] The measurement of the hysteresis loop under room temperature was carried out to the ceramic element of the present embodiment, and energy storage density, energy storage efficiency calculation, the results are shown in Table 1, figure 2 and Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com