Lanthanum-doped lead zirconate titanate antiferroelectric ceramic and preparation method thereof

A lead zirconate titanate and antiferroelectric technology, which is applied in the field of preparation of lanthanum-doped lead zirconate titanate antiferroelectric ceramics, can solve the problems of changing the phase transition properties of materials and the influence of phase transition properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

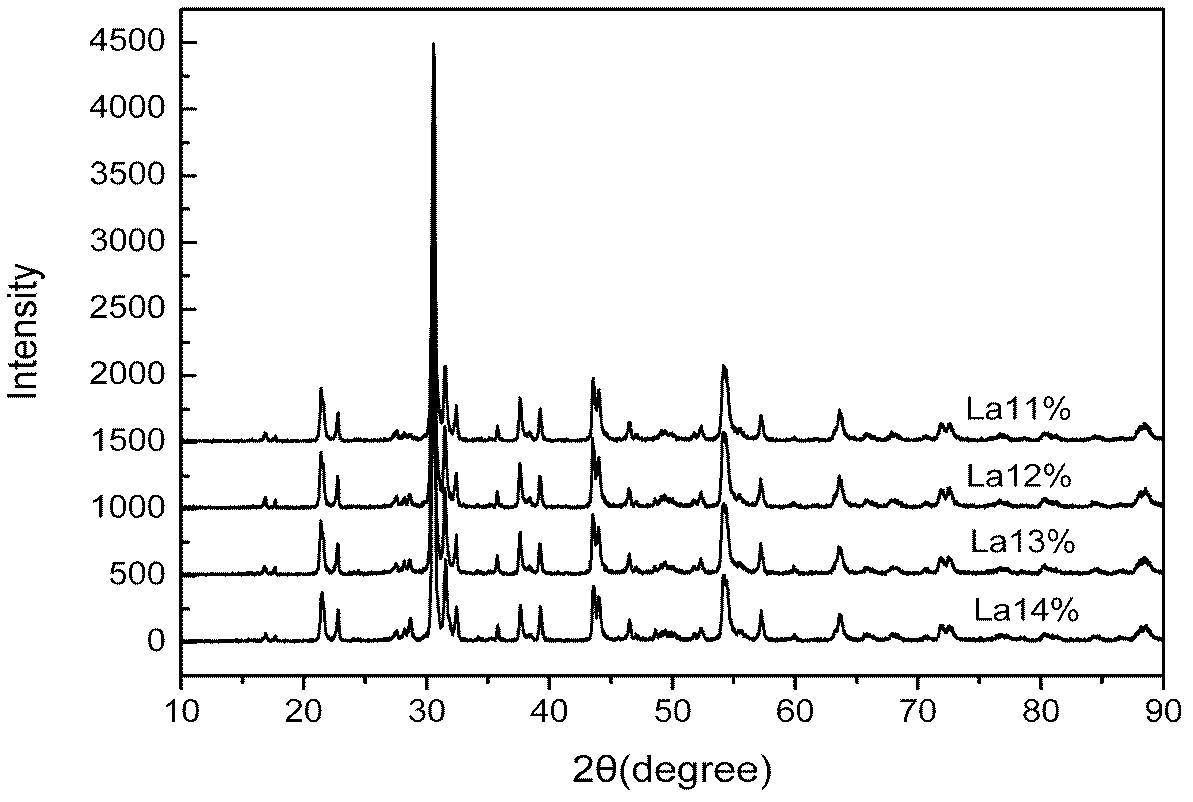

[0027] The present invention adopts commercially available chemically pure raw material (purity ≥ 99%), is Pb 3 o 4 , ZrO 2 、TiO 2 , La 2 o 3 .

[0028] The specific implementation is as follows:

[0029] (1) Ingredients

[0030] Raw material Pb 3 o 4 , ZrO 2 、TiO 2 , La 2 o 3 by Pb 1-x La x (Zr 0.70 Ti 0.30 ) 1-x / 4 o 3 , the stoichiometric ratio batching of x=0.07~0.18 in the formula, mixes in ball mill, ball: material: the weight ratio of water is 2: 1: 0.5, and ball mill medium is deionized water and agate ball, and the rotating speed of ball mill is 750r / min, the ball milling time is 4h, and then the raw materials are dried;

[0031] (2) synthesis

[0032] Put the dried powder in step (1) into an alumina crucible, cover and seal it, and synthesize it at 900°C for 2 hours;

[0033] (3) Molding and ejection

[0034] Ball mill and dry the synthetic material in step (2) again, add 7wt% polyvinyl alcohol aqueous solution to granulate, sieve and press unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com