Samarium-oxide-doped modified lead zirconate titanate ferroelectric ceramic and preparation method thereof

A technology of ferroelectric ceramics and lead zirconate titanate, which is applied in the field of ferroelectric piezoelectric ceramic materials, can solve the problems of performance degradation and achieve the effect of reducing uniform dispersion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

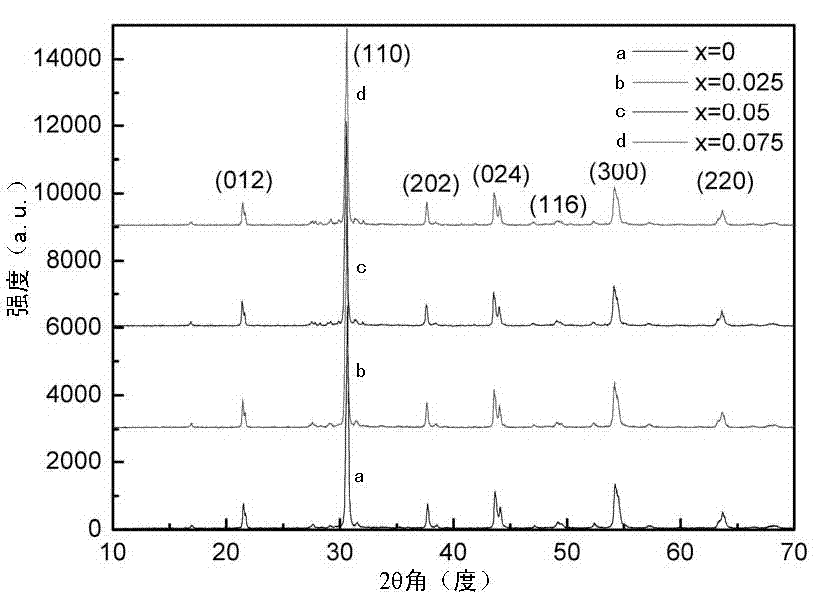

[0036] First according to the general formula Pb 1-x SM x (Zr y Ti 1-y ) 0.98 Nb 0.02 o 3 (x=0, y=0.95) Weigh the stoichiometric ratio of Pb 3 o 4 , ZrO 2 、TiO 2 and Nb 2 o 5 Each raw material is mixed with powder by wet ball milling method to make it evenly mixed. After drying, briquetting is carried out and synthesized at 850°C for 2 hours. ; The mass ratio of ball milling material, ball milling medium and deionized water is 1:1.5:0.6, the ball milling time is 24 hours, and the ball milling medium is steel balls. After the slurry is dried, add PVA binder according to the mass ratio of 7%, granulate, age for 24 hours, pass through a 30-mesh sieve, form under a pressure of 200MPa, and hold the temperature at 750°C for 0.5 hours to discharge the plastic; Sintering is carried out under atmosphere. The sintering process conditions are as follows: heating up to 1000°C at a rate of 2.5°C / min; then raising the temperature to 1330°C at a rate of 1°C / min, holding for 1.5 ...

Embodiment 2

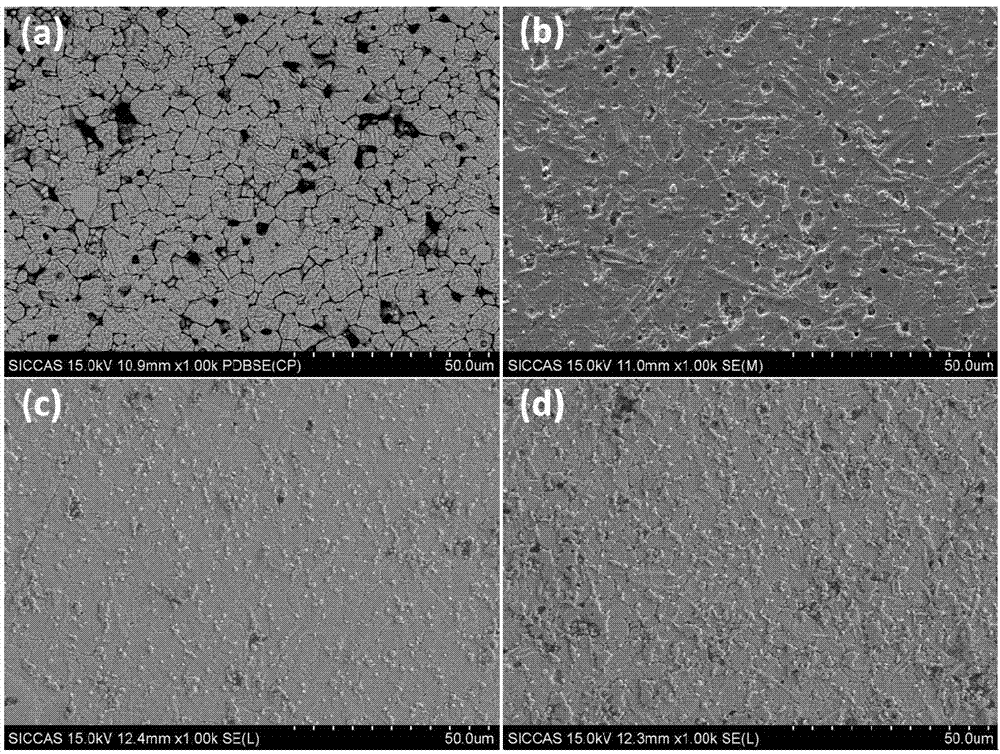

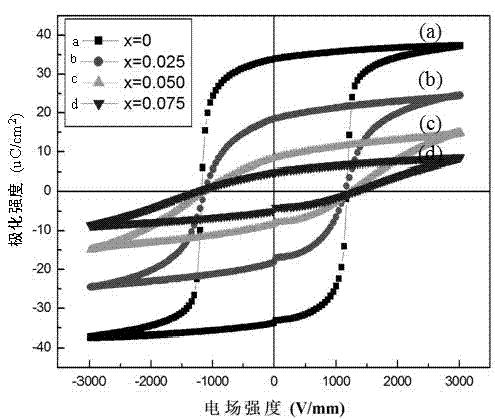

[0039] The only difference between this embodiment and embodiment 1 is: according to the general formula Pb 1-x SM x (Zr y Ti 1-y ) 0.98 Nb 0.02 o 3 (x=0.025, y=0.95) Weigh the stoichiometric ratio of Pb 3 o 4 , ZrO 2 、TiO 2 , Nb 2 o 5 and Sm 2 o 3 Each raw material. Other contents of this embodiment are the same as those described in Embodiment 1. The resulting ceramic has a density of ~7.6 g / cm 3 , Curie temperature Tc=213℃, Young's modulus Y 11 =1.35×10 11 m 2 / N,d 33 =~50pC / N, the resistivity is ~7×10 12 Ωcm. from image 3 It can be seen from the curve b in the ceramic that the remnant polarization strength is 18μC / cm 2 .

Embodiment 3

[0041] The only difference between this embodiment and embodiment 1 is: according to the general formula Pb 1-x SM x (Zr y Ti 1-y ) 0.98 Nb 0.02 o 3 (x=0.05, y=0.95) Weigh the stoichiometric ratio of Pb 3 o 4 , ZrO 2 、TiO 2 , Nb 2 o 5 and Sm 2 o 3 Each raw material. Other contents of this embodiment are the same as those described in Embodiment 1. The prepared ceramic density is 7.6g / cm 3 , Curie temperature Tc=214℃, Young's modulus Y 11 =1.32×10 11 m 2 / N,d 33 =45pC / N, the resistivity is ~1×10 13 Ωcm. from image 3 From the curve c in the figure, it can be seen that the remnant polarization of the ceramic is 10μC / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com