Similar linear lead-free relaxor ferroelectric ceramic material and preparation method thereof

A ferroelectric ceramic, linear-like technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of effective energy storage efficiency disclosure, large remanent polarization, and low energy storage density, and achieve easy control of reaction conditions and preparation Simple method and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

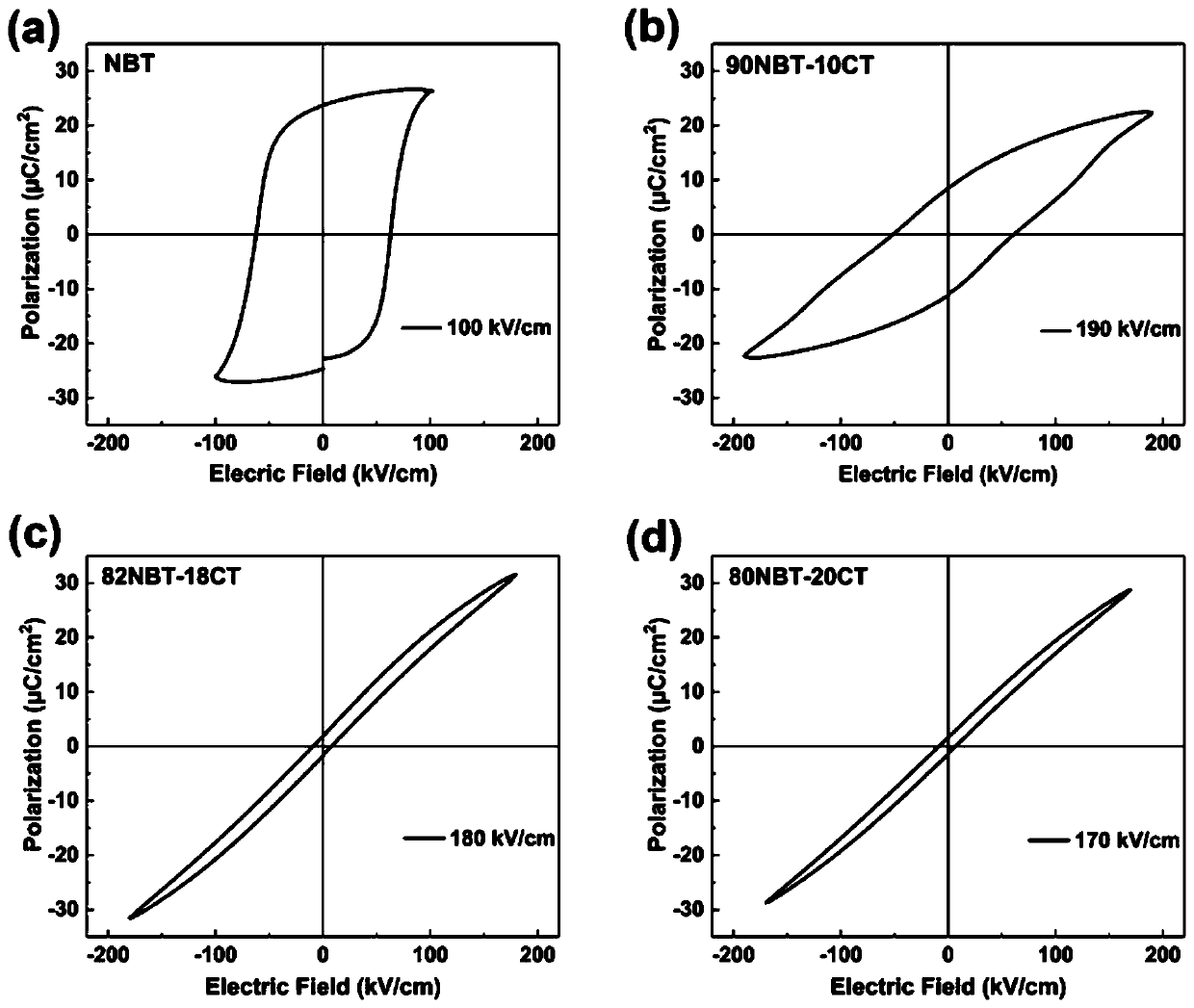

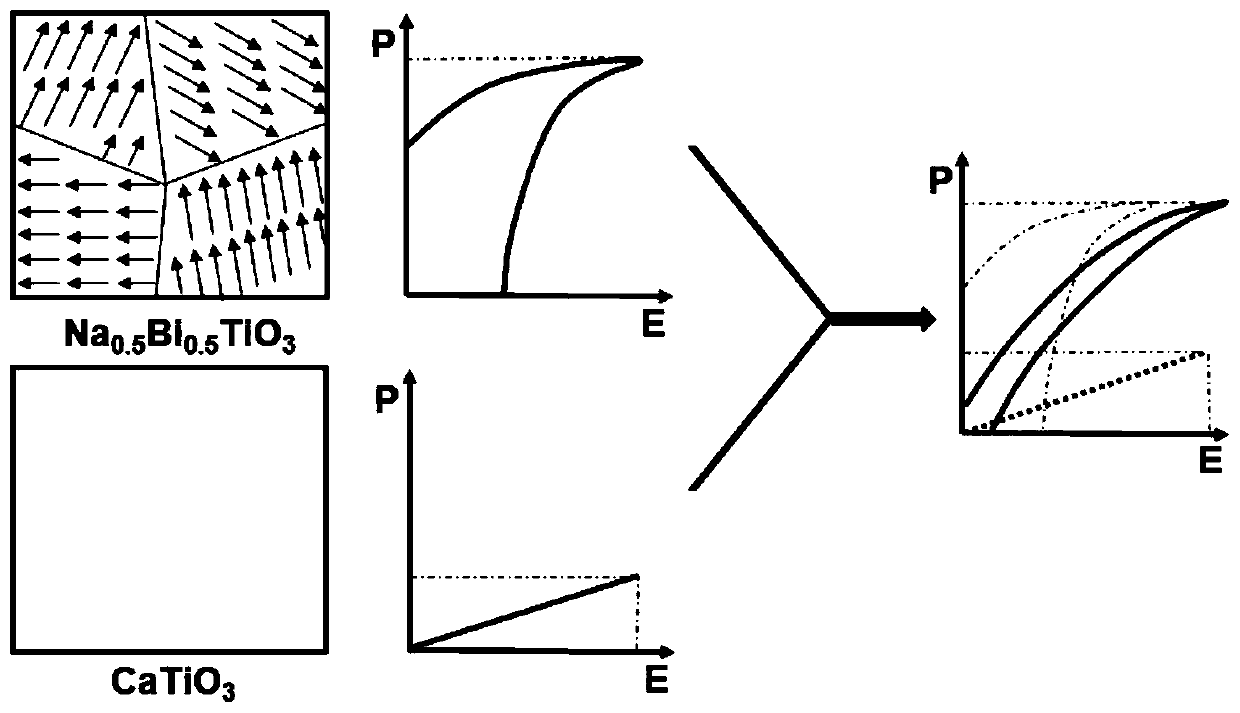

Problems solved by technology

Method used

Image

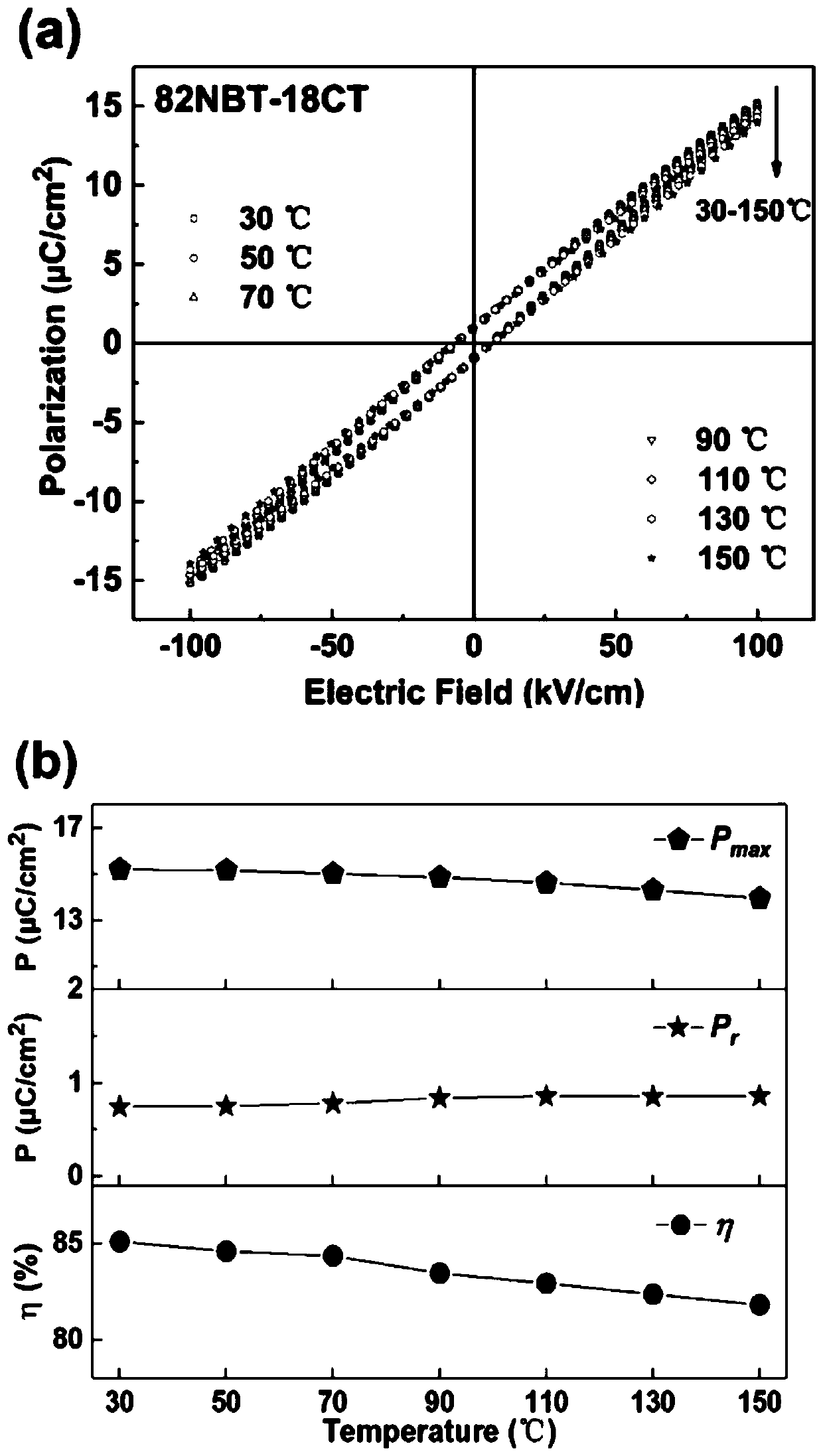

Examples

Embodiment 1

[0037] The prepared chemical composition is 0.82Na 0.5 Bi 0.5 TiO 3 -0.18CaTiO 3The quasi-linear lead-free relaxor ferroelectric ceramic material, its preparation method is as follows:

[0038] (1) Na with a purity of not less than 99% 2 CO 3 、 Bi 2 o 3 , CaCO 3 and TiO 2 The raw materials are mixed according to the molar ratio of 41:41:18:100 and then put into the ball milling tank. At the same time, absolute ethanol (the volume ratio of absolute ethanol to the raw materials participating in the ball milling is 2:1) and zirconia balls are added to the ball milling tank. (The volume ratio of zirconia balls to the raw materials participating in ball milling is 3:2), carry out ball milling for 24 hours at a speed of 270r / min, and dry the mixture obtained after drying (the temperature during the drying process is 70°C);

[0039] (2) Grinding and briquetting the mixture obtained in step (1), pre-burning at 950°C and keeping it warm for 2 hours, and then ball milling (the ...

Embodiment 2

[0046] The prepared chemical composition is 0.82Na 0.5 Bi 0.5 TiO 3 -0.18CaTiO 3 The quasi-linear lead-free relaxor ferroelectric ceramic material, its preparation method is as follows:

[0047] (1) Na with a purity of not less than 99% 2 CO 3 、 Bi 2 o 3 , CaCO 3 and TiO 2 The raw materials are mixed according to the molar ratio of 41:41:18:100 and then put into the ball milling tank. At the same time, absolute ethanol (the volume ratio of absolute ethanol to the raw materials participating in the ball milling is 2:1) and zirconia balls are added to the ball milling tank. (The volume ratio of zirconia balls to the raw materials participating in the ball milling is 3:2), carry out ball milling at a speed of 330r / min for 24 hours, and dry the mixture obtained after drying (the temperature during the drying process is 70°C);

[0048] (2) Grinding and briquetting the mixture obtained in step (1), pre-burning at 950°C and keeping it warm for 2 hours, and then ball milling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com