Low-temperature sintered ternary system relaxor ferroelectric ceramic material, preparation method and application of low-temperature sintered ternary system relaxor ferroelectric ceramic material

A low-temperature sintering technology for ferroelectric ceramics, which is applied in the field of ternary system relaxor ferroelectric ceramic materials, can solve the problems of material component deviation, high sintering temperature, and electrical performance degradation, and achieve high-field piezoelectric performance improvement, Effects of high electrical performance and enhanced temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

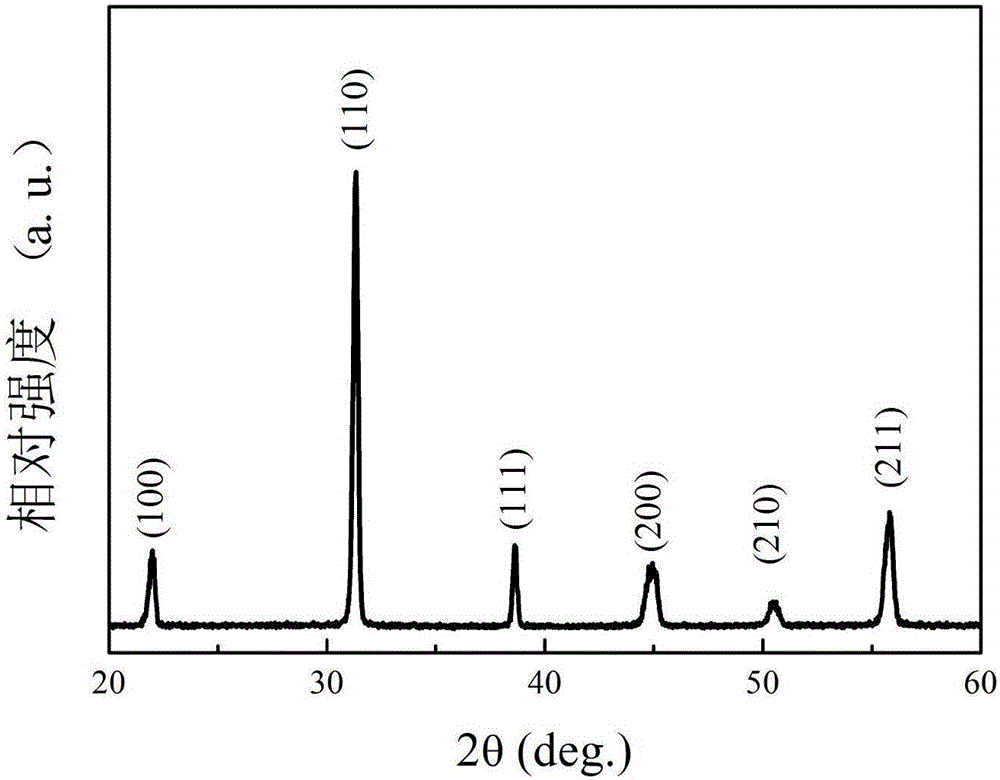

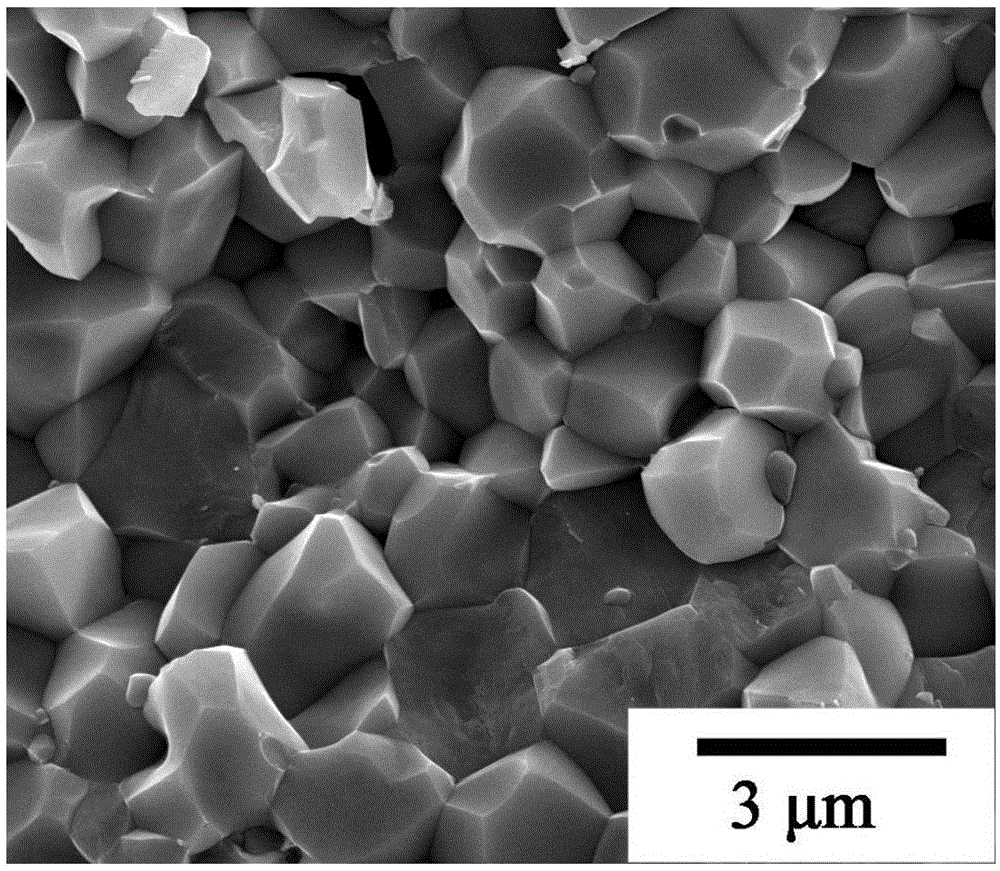

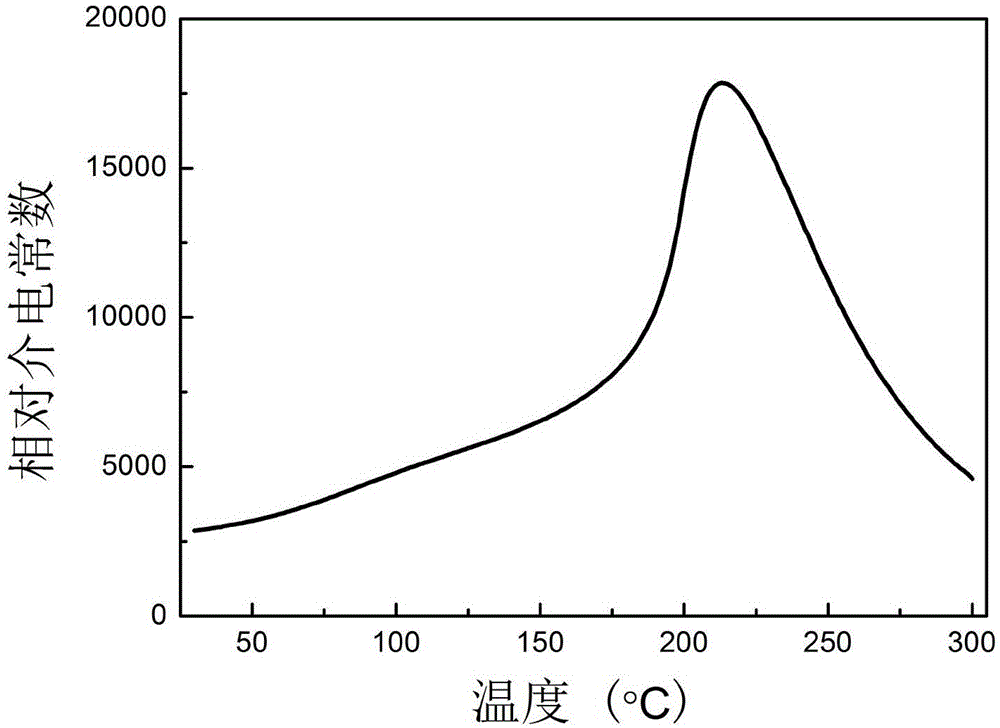

[0019] Specific embodiment 1: The chemical formula of a low-temperature sintered ternary relaxor ferroelectric ceramic material in this embodiment is xPb(In 1 / 2 Nb 1 / 2 )O 3 -(1-x-y)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -yPbTiO 3 -awt.%CuO, where 0.16≤x≤0.36, 0.32≤y≤0.36, 0 <a≤2.

specific Embodiment approach 2

[0020] Specific implementation manner 2: The preparation method of a low-temperature sintered ternary system relaxor ferroelectric ceramic material of this embodiment is completed in the following steps:

[0021] 1. Using solid-phase reaction method to synthesize pure phase MgNb 2 O 6 Precursor powder

[0022] 2. Using solid phase reaction method to synthesize pure phase InNbO 4 Precursor powder

[0023] 3. Using PbO, TiO 2 , The pure phase of MgNb obtained in step one 2 O 6 Precursor powder and pure phase InNbO obtained in step 2 4 The precursor powder is used as the raw material, and the pure phase xPb(In 1 / 2 Nb 1 / 2 )O 3 -(1-x-y)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -yPbTiO 3 Matrix powder, where 0.16≤x≤0.36, 0.32≤y≤0.36;

[0024] 4. The pure phase xPb(In 1 / 2 Nb 1 / 2 )O 3 -(1-x-y)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -yPbTiO 3 The matrix powder is used as the raw material, and the low-temperature sintered ternary system relaxor ferroelectric ceramic material is prepared by solid-phase synthesis preparation technolog...

specific Embodiment approach 3

[0025] Specific embodiment three: This embodiment is different from the specific embodiment two in that: in step one, a solid phase reaction method is used to synthesize pure phase MgNb 2 O 6 The precursor powder is specifically carried out according to the following steps:

[0026] According to the chemical formula as MgNb 2 O 6 Weigh MgO and Nb 2 O 5 , Will weigh the MgO and Nb 2 O 5 Mix and place in a polyethylene ball milling tank, with absolute ethanol as the ball milling medium, agate ball as the milling ball, ball mill for 24h~72h to obtain wet material A after ball milling, and place the wet material A after ball milling at a temperature of 50℃ Dry in an oven at ~100℃ to obtain dry block A. Place the dry block A in an agate mortar to grind and crush to obtain powder A. Then, place the powder A in an alumina crucible with a lid. Pre-sintering at 1000℃~1150℃ for 2h~6h to obtain pure phase MgNb 2 O 6 Precursor powder. Others are the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com