Rice husk carbon-based water retention agent preparation method and rice husk carbon-based water retention agent

A technology of water retaining agent and rice husk charcoal, which is applied in the fields of agriculture and forestry to achieve the effects of large-scale production, promotion of application range, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

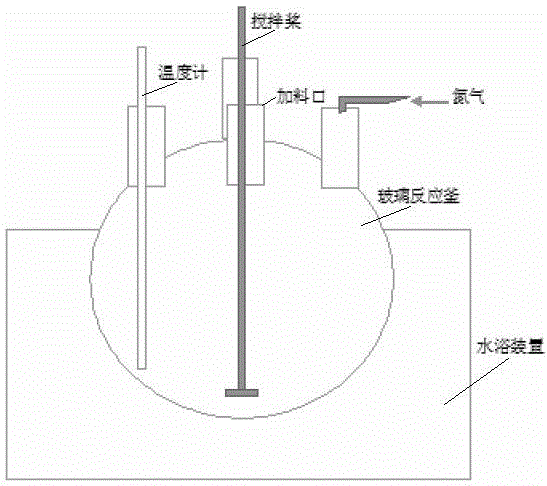

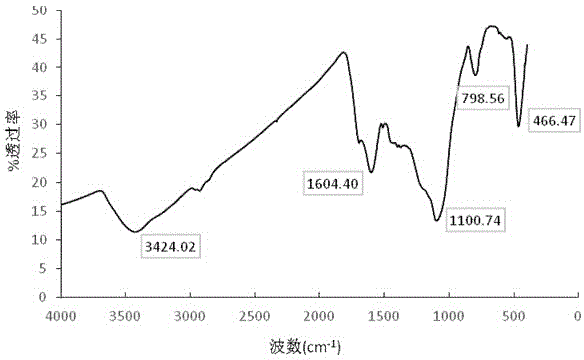

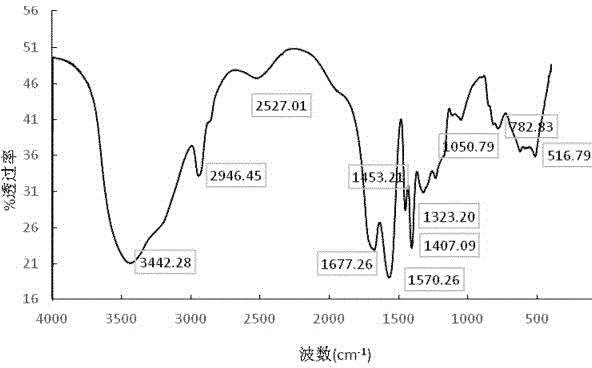

[0025] see Figure 1 to Figure 4 , The steps of the preparation method of rice husk charcoal-based water retaining agent in the present embodiment are as follows.

[0026] The water-absorbing resin in this example is carried out in a four-port glass reactor, and the specific device schematic diagram can be found in figure 1 . First dilute the acrylic acid monomer with deionized water to a mass percent concentration of 50%, and then add it into the reaction kettle. Add the crushed and 200-mesh sieved rice husk charcoal into the reaction kettle, pass nitrogen gas, and turn on the stirring paddle. The stirring speed is 550-800r / min, which is more economical. and hold for 10 minutes. Then from the feeding port, use a separatory funnel to slowly drop in an aqueous NaOH solution with a mass percent concentration of 40%. Since the neutralization of acrylic acid and NaOH is an exothermic reaction, normal temperature water (25°C) is passed into the water bath for cooling. According...

Embodiment 2

[0034] The steps of the preparation method of the rice husk charcoal-based water retaining agent in this example are as follows: the rice husk is carbonized for 30-90 minutes at a temperature of 280-400°C and the oxygen volume content is less than or equal to 5% to obtain a carbonized product, and the obtained carbonized product is pulverized , cross 200 mesh sieves to obtain rice husk charcoal powder; the rice husk charcoal powder crossing 200 mesh sieves is mixed in the reactor with the ratio of 0.5% mass fraction of acrylic acid and the aqueous solution of acrylic acid monomers with a mass percentage concentration of 50%. The rotating speed of the kettle stirring blade is 600r / min. Under normal temperature water bath conditions, drop 40% sodium hydroxide aqueous solution into the acrylic acid reaction system through a separatory funnel, the acid-base neutralization degree is 60%, and the temperature of the reaction system is controlled below 40°C during this process , such ...

Embodiment 3

[0038] The steps of the preparation method of the rice husk charcoal-based water retaining agent in this example are as follows: the rice husk is carbonized for 30-90 minutes at a temperature of 280-400°C and the oxygen volume content is less than or equal to 5% to obtain a carbonized product, and the obtained carbonized product is pulverized , cross 200 mesh sieves to obtain rice husk charcoal powder; the rice husk charcoal powder crossing 200 mesh sieves is mixed in the reactor with the ratio of 1% mass fraction of acrylic acid and the aqueous solution of acrylic acid monomer of 50% mass percentage concentration, and the reaction The stirring speed of the kettle stirring paddle is 600r / min. Under normal temperature water bath conditions, 40% sodium hydroxide aqueous solution is dripped into the acrylic acid reaction system through a separatory funnel, and the acid-base neutralization degree is 60%. During this process, the temperature of the reaction system is controlled belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com