Preparation method of graphene nanoribbon in situ toughened nano carbon fiber

A technology of graphene nanobelts and nanocarbon fibers, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of high energy consumption, complex process, high melt spinning temperature, etc., and achieve low energy consumption, simple process and few processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

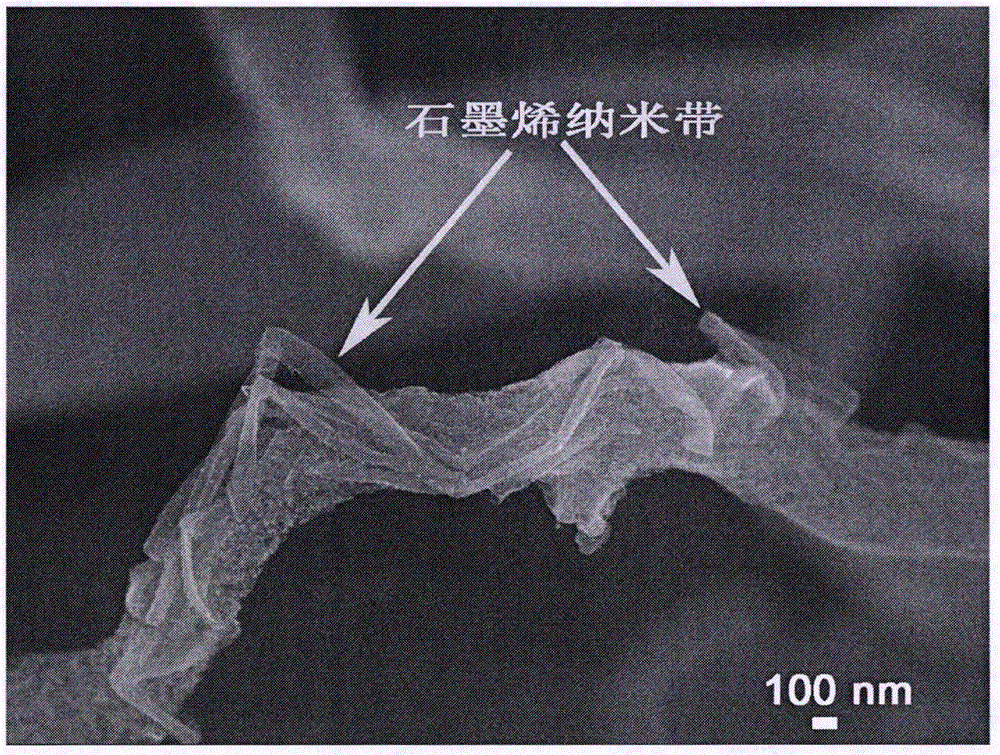

Image

Examples

Embodiment 1

[0026] A preparation method for in-situ toughened carbon nanofibers of graphite graphene nanobelts, the specific steps are as follows:

[0027] ((1) Preparation of carbon nanofiber precursor

[0028] Preparation of carbon nanofiber precursor solution A, the concentration of polymer in the solution A is 60g / L; the solution A is stirred, the stirring time is 8h, and the stirring temperature is 60°C to obtain a uniform solution A.

[0029] (2) Dispersion of graphene nanoribbons

[0030] The aqueous solution B of preparation tensio-active agent, the concentration of tensio-active agent in the described solution B is 0.5g / L; Graphene nanoribbon is dispersed in solution B, prepares solution C, the graphene nanoribbon in above-mentioned solution C The concentration is 0.2g / L; ultrasonically oscillate the solution C, the ultrasonic power is 200W, and the ultrasonic time is 10min to obtain a uniform solution C; the solution C is frozen, the freezing temperature is -20°C, and the freez...

Embodiment 2

[0036] A preparation method for in-situ toughened carbon nanofibers of graphite graphene nanobelts, the specific steps are as follows:

[0037] (1) Preparation of carbon nanofiber precursor

[0038] Preparation of carbon nanofiber precursor solution A, the concentration of polymer in the solution A is 200g / L; the solution A is stirred for 8 hours and the stirring temperature is 25°C to obtain a uniform solution A.

[0039] (2) Dispersion of graphene nanoribbons

[0040] Prepare the aqueous solution B of surfactant, the concentration of surfactant in the solution B is 2g / L; Graphene nanobelt is dispersed in solution B, prepares solution C, the concentration of graphene nanobelt in above-mentioned solution C was 0.4g / L; the solution C was ultrasonically oscillated, the ultrasonic power was 400W, the ultrasonic time was 30min, and a uniform solution C was obtained; the solution C was frozen, the freezing temperature was -40°C, and the freezing time was 6h; The solution C was free...

Embodiment 3

[0046] A preparation method for in-situ toughened carbon nanofibers of graphite graphene nanobelts, the specific steps are as follows:

[0047] (1) Preparation of carbon nanofiber precursor

[0048] Preparation of carbon nanofiber precursor solution A, the concentration of polymer in the solution A is 130g / L; the solution A is stirred for 28 hours and the stirring temperature is 42°C to obtain a uniform solution A.

[0049] (2) Dispersion of graphene nanoribbons

[0050] The aqueous solution B of preparation tensio-active agent, the concentration of tensio-active agent in the described solution B is 1.25g / L; Graphene nanoribbon is dispersed in solution B, prepares solution C, the graphene nanoribbon in above-mentioned solution C The concentration is 0.3g / L; ultrasonically oscillate the solution C, the ultrasonic power is 300W, and the ultrasonic time is 20min to obtain a uniform solution C; the solution C is frozen, the freezing temperature is -30°C, and the freezing time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com