Composite filtering material fiber used for SCR dust removal and denitration and preparation method of same

A composite filter material and fiber technology, which is applied in the post-treatment of nitrogen oxides and pollutant dust, to achieve the effects of strengthening the bonding strength, simplifying the process, and improving the denitrification efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

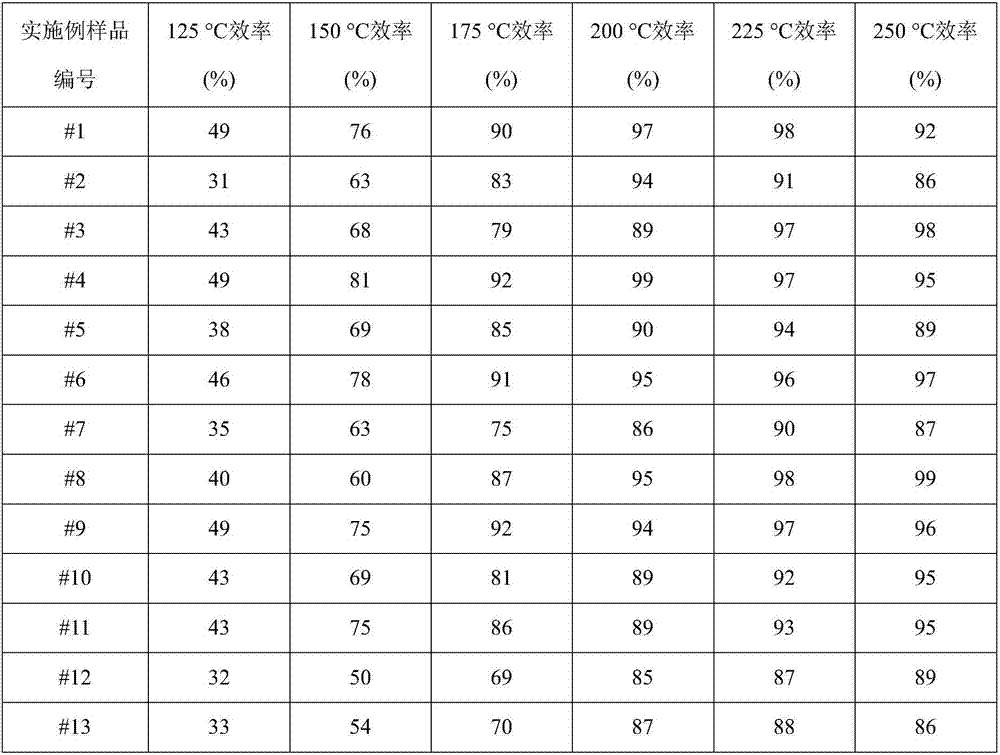

Examples

Embodiment 1

[0042] The steps of the composite filter fiber used for SCR dust removal and denitration based on polyimide fiber are as follows:

[0043] Step 1: Weigh 14.32g of 50wt% manganese nitrate solution, 4.34g of cerium nitrate hexahydrate, and 4.29g of zirconium nitrate pentahydrate, dissolve them in 250mL of deionized water, stir evenly to obtain solution A. Take 16 mL of 25 wt% ammonia aqueous solution, dilute to 200 mL with deionized water, and stir to obtain solution B (pH 10).

[0044] Step 2: Immerse the polyimide fiber in solution A for 40 minutes, and ultrasonic assist time for 7 minutes, then take out the infiltrated polyimide fiber from solution A, drain and immerse it in solution B, immerse and settle for 21 minutes, take out the fiber, and place The air atmosphere is aged for 4h.

[0045] Step 3: Put the aged fiber in a microwave reactor, microwave heat treatment for 20min, reaction conditions: microwave power 200W, microwave generation time 10s every 20s; then put it in a bla...

Embodiment 2

[0047] This example is the same as Example 1, except that the 50wt% manganese nitrate solution of this example is 3.58g, cerium nitrate hexahydrate 17.36g, and zirconium nitrate pentahydrate 4.29g, to obtain a bifunctional composite that supports metal oxides firmly Fiber #2.

Embodiment 3

[0049] This example is the same as Example 1, except that the 50wt% manganese nitrate solution of this example is 3.58g, cerium nitrate hexahydrate 4.34g, and zirconium nitrate pentahydrate 17.16g, to obtain a bifunctional composite that supports metal oxides firmly. Fiber #3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com