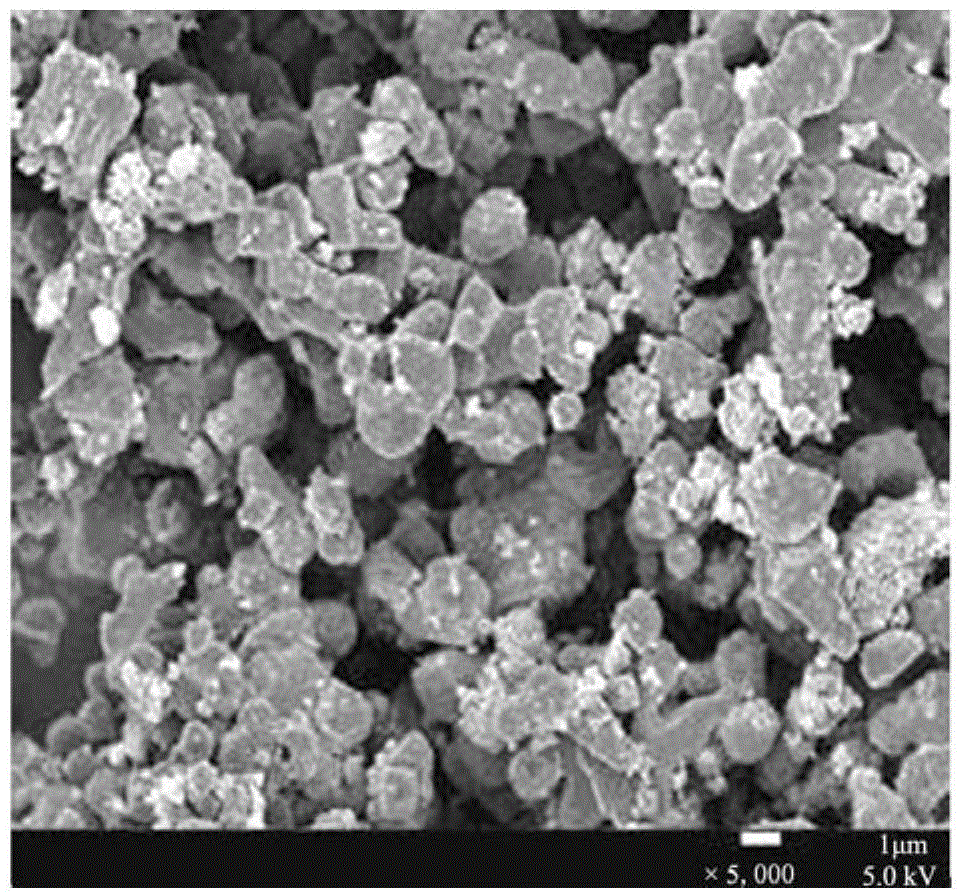

Rotation type dynamic continuous preparing method and device for (M1, M2)(CxN1-x) powder

A rotary dynamic and sintering device technology, which is applied in the direction of rotary drum furnace, lighting and heating equipment, furnace components, etc., can solve the problems of high cost, serious product bonding, and long time required for the product, so as to facilitate processing and production, The effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

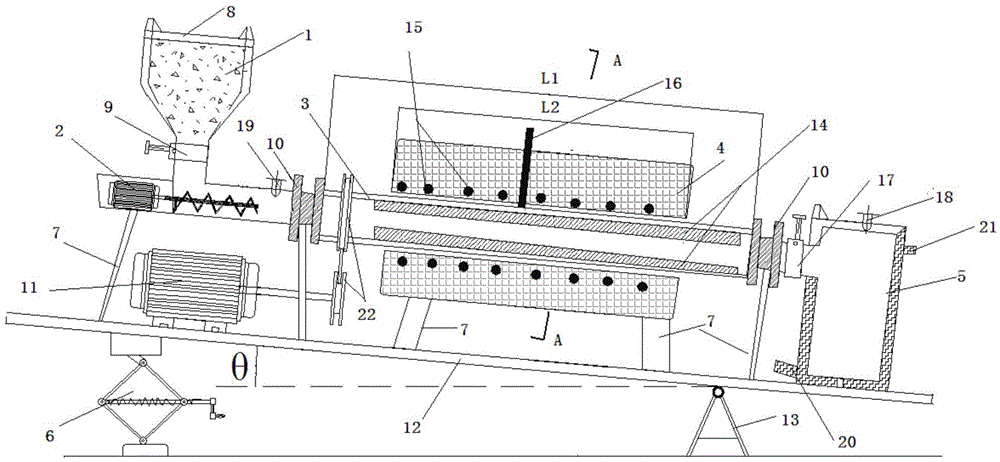

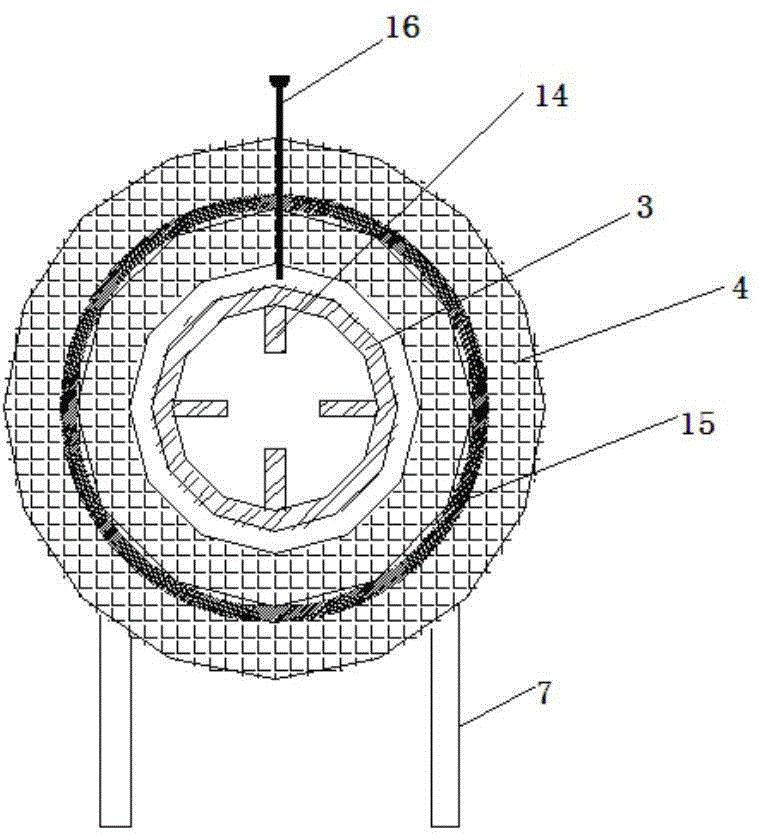

[0042] In this embodiment, the structure of the rotary dynamic continuous sintering device is as follows figure 1 as shown, figure 2 for figure 1 The A-A sectional view of the rotary dynamic continuous sintering device is composed of a storage chamber 1, a screw feeder 2, a furnace tube 3, a furnace tube drive mechanism, a heating furnace 4, a collection chamber 5, a support frame, a threaded lifter 6 and a support frame 7; the discharge end of the screw feeder 2 is provided with an air inlet valve 19, the top of the storage chamber 1 is provided with a sealing cover 8, and the bottom of the storage chamber 1 is provided with a discharge control valve 9. The discharge port at the bottom of the material chamber 1 is connected to the screw feeder 1; the heating furnace 4 is provided with a resistance heating device 15 and a thermocouple 16; The inlet of the collection chamber 5 is provided with a feed control valve 17, the chamber wall of the collection chamber 5 is a sandwic...

Embodiment 2

[0056] In this embodiment, the structure of the rotary dynamic continuous sintering device is basically the same as that of the dynamic sintering device described in Embodiment 1, except that the length L1 of the furnace tube 3 is 3 m, and the length L2 of the heating zone of the heating furnace 4 is 2m, the number of stirring pieces 14 is 2 pieces.

[0057] (Ti,10Ta,5Nb)(C 0.9 N 0.1 ) The rotary dynamic continuous preparation method of powder is as follows:

[0058] (1) Ingredients

[0059] The raw material is TiO 2 Powder, Ta 2 o 5 Powder, Nb 2 o 5 Powder and graphite powder, the ratio of each raw material to the total mass of raw materials is as follows:

[0060]

[0061] (2) Mixing and drying

[0062] Put the raw materials measured in step (1) into a rolling ball mill, add cemented carbide balls as grinding balls, the ball-to-material ratio (mass ratio) is 4:1, add absolute ethanol and water as ball milling media, absolute ethanol The mass ratio to water is 3:1,...

Embodiment 3

[0068] In this embodiment, the structure of the rotary dynamic continuous sintering device is basically the same as that of the dynamic sintering device described in Embodiment 1, except that the length L1 of the furnace tube 3 is 4 m, and the length L2 of the heating zone of the heating furnace 4 is 3m, the number of stirring pieces 14 is 3 pieces.

[0069] (Ti,40W)(C 0.3 N 0.7 ) The rotary dynamic continuous preparation method of powder is as follows:

[0070] (1) Ingredients

[0071] The raw material is TiO 2 Powder, WO 3 Powder and activated carbon powder, the ratio of each raw material to the total mass of raw materials is as follows:

[0072] TiO 2 Powder 27.7%

[0073] WO 3 Powder 53.6%

[0074] Activated Charcoal Powder 18.7%

[0075] (2) Mixing and drying

[0076] Put the raw materials measured in step (1) into a rolling ball mill, add cemented carbide balls as grinding balls, the ball-to-material ratio (mass ratio) is 10:1, add absolute ethanol as the ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com