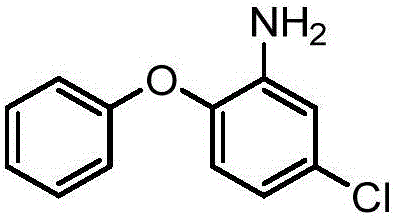

Method for preparing 2-amino-4-chlorodiphenyl oxide

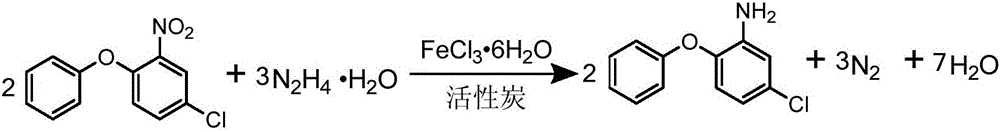

A technology of chlorodiphenyl ether and amino, which is applied in the field of preparing 2-amino-4-chlorodiphenyl ether by reducing 2-nitro-4 chlorodiphenyl ether with hydrazine hydrate, which can solve the problem of high equipment requirements and harsh hydrogenation conditions , unfavorable industrial promotion and other issues, to achieve the effect of increasing reaction yield, improving conversion rate, and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the reaction flask, add 2-nitro-4-chlorodiphenyl ether 30g, industrial alcohol 90mL, ferric chloride hexahydrate 5g, activated carbon 5g, stir and use 7g liquid caustic soda (mass percentage concentration is 30% sodium hydroxide aqueous solution ) adjust the pH value to 7.3, heat up to 80-90°C, slowly add 13g of hydrazine hydrate with a mass percentage concentration of 85% to the system under reflux, drop it in about 2 hours, continue to reflux for 3 hours, filter while it is hot, and recover the filtrate by distillation After alcohol, add water and stir for 30 minutes, stand still and separate liquid to obtain 24.85g of light brown oily product, 2-amino-4-chlorodiphenyl ether has a purity of 99.04%, a content of 98.65%, and a product yield of 92.82%.

Embodiment 2

[0030] In the reaction flask, add 2-nitro-4-chlorodiphenyl ether 30g, denatured alcohol 90mL, ferric chloride hexahydrate 5g, gac 5g, stir and adjust the pH value to 9.5 with 9g liquid caustic soda (30%), heat up to 80-90°C, slowly add 13g of hydrazine hydrate with a concentration of 85% to the system under reflux, and drop it in about 2 hours. Continue to reflux for 3 hours and then filter while it is hot. The liquid obtained 21.88g of a dark brown product, the purity of 2-amino-4-chlorodiphenyl ether was 94.74%, the content was 91.55%, and the product yield was 75.85%.

Embodiment 3

[0032] In the reaction flask, add 2-nitro-4-chlorodiphenyl ether 30g, technical alcohol 90mL, ferric chloride hexahydrate 5g, gac 5g, stir and adjust the pH value to 7.5 with 7g liquid caustic soda (30%), be warming up to 80-90°C, slowly add 12g of hydrazine hydrate with a concentration of 85% to the system under reflux, and drop it in about 2 hours. After continuing to reflux for 3 hours, filter while it is hot. After the filtrate is distilled to recover alcohol, add water and stir for 30 minutes. The liquid obtained 22.80 g of light brown product, the purity of 2-amino-4-chlorodiphenyl ether was 98.76%, the content was 95.77%, and the product yield was 82.27%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com